|

Obsolete Outboards |

|

| by

Max Wawrzyniak - St Louis, Missouri - USA

Bringing

a 1956 Johnson 15 hp Back to Life

Part

IV: Magneto

Work |

|

Part

1 - Part

2 - Part 3 - Part

5 - Part 6 - Part

7

Have a good look at figure SF 25 (below). This is

your magneto. This is the thingy that makes the spark

plugs spark. In the very center is the crankshaft

(which you will not see on your magneto if you have

already removed the magneto from the engine. Instead,

you will see a hole where the crankshaft fits). Doo-dad

#4 is a cam (eccentric) which is a slip-fit on the

crankshaft. As the crankshaft rotates, the cam alternately

opens and closes the ignition points ("breaker"

points) which are #'s 10 and 20. You will see the

spring-loaded rocker arms which ride on the cam, and

which have the points at their outer ends. We are

going to install new points, but just as an "FYI,"

the most common problems with old points are that

their contact surfaces are dirty and/or pitted and

eroded. You can "clean-up" pitted points

with a special little points file or a bit of emory

cloth, and you can clean dirty points by allowing

the points to close on a bit of clean business card

and pulling the card out from between the closed points

several times. Other problems that occasionally show-up

are weak return springs and bent points rocker arms.

Have a look at figure SF 26 for some other protential

problems. Since most of these parts are pretty cheap

and you already have the engine apart, I suggest just

replacing the points and condensers. Why screw with

trouble-shooting old parts?

|

SF25 -

The magneto and it's parts

(click

images to enlarge) |

|

Numbers 2 and 13 on figure SF 25 are the condensers,

which have nothing to do with steam as their name

suggests. Some have commented that a more appropriate

term would be capacitor. Anyway, the condensers act

as short-term (very short-term, like a fraction of

a second) electrical current storage devices. Sort

of like a battery, but different. I won't go into

more detail because it will bore you and you don't

need to know more about condensers than I have already

written, and also because I really don't remember

much more about condensers and would have to look

it up. I do remember that condensers can fail in two

different ways. Notice that the condenser is a little

metal cylinder with a wire sticking out the end of

it. One way the condenser can fail is for there to

be short circuit between that wire and the metal case

of the condenser. This is easy to check for if one

has a multi-meter or even a little battery-powered

test light. There should be no electical connection

between the metal case and the wire; if there is,

the condenser is shorted and junk. The second way

a condenser can fail is that it can have an internal

problem that makes it weak or ineffective. One needs

a special testing device for detecting this problem.

But condensers for our favorate old OMC outboards

from 1955 to 1972 (are so) are dirt-cheap to buy so

why bother with testing old condensers at all? Just

replace them.

| SF26 - Yeah,

you've seen this before. You know, you can

replace most of this stuff pretty cheaply

and then you don't have to trouble-shoot

problems with it. |

|

|

Numbers 5 and 16 on SF 25 are the coils. As with

the points and condensers, there is one for each cylinder.

The coils are cylindrical plastic things mounted on

the middle "leg" of a three leg metal thing

constructed of many layers of metal riveted together.

The plastic coils and the laminated metal are considered

a single component in these old OMC engines, although

with other brands of engines one could replace the

plastic coil separately from the laminated metal thing.

The coils orignally installed in these old OMC engines

always went bad, without exeception. If the coils

on your engine have cracks in the plastic casing,

they are bad. No cracks, and probably your engine

has had replacement coils installed and most likely

they are good. Uncracked coils can go bad but it is

rare, and anyway the only way to test them is to use

a special testing device, which you don't have. You

can spend a lot of money buying one...

or if you are handy you can try building

your own coil tester... or you might be able to take

your coil to a local small engine/outboard motor repair

shop and have them test it for you. I just assume

that if the things are not cracked, they are good,

and I don't give them a second thought unless I have

already replaced the points, condensers, spark plug

wires and spark plugs and still do not get a spark.

|  SF27

- How to install the spark plug boots

on the ends of the spark plug wires. Make

sure that the pointed end of the coiled

wire goes through the center of the spark

plug wire so as to make contact with the

wire core of the spark plug wire. Disregard

#5; you won't have a choice like the old

boys did 50 years ago. The "slip-one"

end is the only end available on Champion

J8C plugs (or equivalent) , which are

the plugs recommended for most 1950's

and 1960's OMC outboards of under 35 hp

or so. SF27

- How to install the spark plug boots

on the ends of the spark plug wires. Make

sure that the pointed end of the coiled

wire goes through the center of the spark

plug wire so as to make contact with the

wire core of the spark plug wire. Disregard

#5; you won't have a choice like the old

boys did 50 years ago. The "slip-one"

end is the only end available on Champion

J8C plugs (or equivalent) , which are

the plugs recommended for most 1950's

and 1960's OMC outboards of under 35 hp

or so.

|

|

What about them spark plug wires? Chances are they

are the orginal wires and that they are getting old

and stiff and cracking. Unless you are real sure that

the wires have been replaced at some point in the

recent past, I would go ahead and replace them. They

could have some small cracks that could cause short

circuits and could drive you nuts trying to track-down

the problem. I try to minimize frustrations in my

life, so I always replace the wires. You will need

some metallic-core spark plug wire, which you can

usually buy by the foot. I use Sierra-brand spark

plug wire, which I bought a while back

in a 100 foot reel - part # 18-5226. Sierra also sells

a package containing 25 feet of wire and a bunch of

useless (to you) fittings, part # 18-5225. Since you

will need a lot less wire (measure the lengths of

your old wires, allow a bit extra, and note that the

wires are of different lengths), try calling local

boat dealerships and small engine repair shops and

you will find people selling this stuff by the foot.

There are other brands, of course, but do not get

talked into buying graphite-core wire. Before you

close-out the PDF, note the spark plug boots, 18-5750.

I always re-use the old boots on new wires, unless

the old boots are torn.

The spark plug wires are removed from the coils

by simply pulling on the wires; there is a little

spike inside the hole in the coil on which the wire

is impaled. The rubber boots on the other end of the

wires can also just be pulled off but try not to tear

the rubber. Note the little wire scroll inside the

boot; it is a seperate piece and not molded as part

of the boot. Figure SF27 shows how to install the

boots on the new wires. Note that #4 recommends the

use of a special silicone lubricant to make installing

the boot easier; it is really really hard to get one

of these boots on without some kind of lubricant.

I usually use an ordinary silicone spray lubricant

, but have on occasion used a drop of 2-cycle motor

oil. Don't use too much lubricant. Also, disregard

# 5 on SF 27; times have changed and one no longer

has a choice of terminals on one's spark plugs. By

the way, the spark plugs to use on this 1956 15 hp.

and on virtually all 1950's and 1960's OMC's are Champion

J8C or equivalent.

| SF28 - You

have to remove stuff from the underside

of the magneto in order to remove the spark

plug wires. The plug wire for the top cyclinder

is usually marked with a little metal band;

keep track of which wire is which. |

|

|

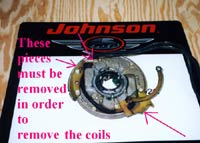

If you are installing new coils or if you are temporaily

removing the old coils in order to install new sparkplug

wires on them you will need to remove some of the

hardware from the bottom of the magneto ("stator")

plate. I really suggest taking careful notes and even

photos as these stator plates often are used on several

different models of engines and so often have extra

holes which may make reinstalling the bits and pieces

more complicated than you think. I find it helpful

to put the screws back into their holes as soon as

a part is removed, rather than tossing all the screws

into a coffee can and then later trying to figure

out which screw went where.

Once the "gingerbread" is off the bottom

of the magneto/stator, you can flip it right side

up and loosen screws #3, 8, & 18, figure SF21,

plus one screw on that diagram which excaped being

numbered. Note that in additon to the fat sparkplug

wire on the bottom, each coil also has a small wire

attached under one of it's mounting screws (a ground

wire) and another small wire that attaches to the

ignition points under a screw which also holds the

wire from the condenser. Unfasten these small wires

and lift the coils off the plate. If you are reusing

the old coils, pull the spark plug wires out of them

and push your new spark plug wires (cut to the appropriate

length) into the hole and secly onto the little spike

inside the hole. Note that there should be a little

rubber boot covering the joint where the spark plug

wire connects to the coil- be sure to re-install the

little boots.

Here's something important: make sure you know which

spark plug wire goes to which cylinder. usually there

is a little metal tag on the "top" spark

plug wire- be sure to transfer it to the new wire.

What happens if you lose track of which is which?

Figure SF25 provides some helpfull hints. Also, if

you try to start an outboard with the spark plug wires

reversed (and everything else is correct) it will

back-fire and yank the starter cord violently out

of your fingers.

|

SF29 -

Stuff removed from underside of magneto.

I always put the screws back into their

holes. Makes keep track of which screw

goes where a lot easier, and lessens the

chance of losing a screw.

|

|

When re-installing the coils to the magneto (stator)

plate, one has to set the "air gap": No

big deal at all, actually; the "air gap' is the

distance between the laminated metal "heels"

of the coils and the inner circumference of the flywheel.

The flywheel contains magnets, and the goal is to

have the coil heels as close to the magnets as possible

with out actually rubbing on the spinning flywheel.

To set the air gap, one merely loosens the coil mounting

screws and moves the coil around until the outer surface

of the heels is flush with a machined surface on the

stator plate directly below the heels. Figure SF30

shows the heels and the surface directly below the

heels; just rub your finger across the joint between

the heels and the machined surface and if you feel

no "step" as your finger crosses the joint,

tighten the coil mounting screws and re-check to make

sure the coil has not moved. Once the coils are mounted

you can put the "gingerbread" items back

on the bottom of the magneto.

With the magneto right-side up, the condensers can

be removed. Have a good look at figure SF30 and SF31:

remove the screw from the points which holds the wires

from the coil and condenser (and the wire from the

kill switch, if your engine has a kill switch). Then

remove the single screw which secures each condenser.

SF30

- Setting the coil "air gap" just

means making sure that the outer ends of

the coil heels are flush with the machined

surface directly below them. The holes in

the coils for their mounting screws are

slightly over-sized so that the coils can

be moved around slightly to make this alignment. SF30

- Setting the coil "air gap" just

means making sure that the outer ends of

the coil heels are flush with the machined

surface directly below them. The holes in

the coils for their mounting screws are

slightly over-sized so that the coils can

be moved around slightly to make this alignment. |

|

Now to the ignition points, AKA "breaker points"

or just "points." The points are actually

in two pieces: a "base plate" and a "rocker

arm." The actual contact surfaces of the points

are two tiny round metal disks, one of which is mounted

on the stationary base plate while the other is mounted

on the rocker arm, which pivots on a little axle or

shaft. The points are spring-loaded to be in the "closed"

closed position (contacts together) and the cam rotating

on the crankshaft moves the opposite end of the rocker

arm to "open" the points. Although you can

buy points and condesners seperately, I would suggest

that you buy a tune-up kit, which includes (2) points

rocker arms, (2) points base plates and (2) condensers.

You need one kit per engine, and you can either get

the official OEM kit from a Johnson or Evinrude dealer,

or you can buy a Sierra brand kit from virtually any

boat dealership (regardless of what engine brand they

carry0 and also from NAPA auto parts stores. The Sierra

kit I used on the 1956 15 hp was part # 18-5006, which

also fits the 5.5 hp, 7.5 hp, and 10 hp models of

the 1950s and early 1960's, and also 18 hp up to about

1961, and a few other models as well. List price for

the kit is about $20.00

Remove the tiny wire clip which holds the rocker

arm onto the littlte shaft that it "rocks"

on (needle nose pliers work well here). Notice also

that there is a flat sheet metal clip (usually copper

colored) which secures the spring that holds the rocker

arm in the "points closed" postion; this

clip needs the be removed as well and then the rocker

arm can be lifted off. The rocker arm shaft is part

of the magneto stator plate and does not come off.

Remove the single screw which secures the points base

plate and then lift off the base plate. Note the "adjuster"

for the base plate; this looks like a screw but it

is not. It is a permanent part of the magneto stato

plate and it is not removed.

|

SF31 -

The various parts of the "points,"

along with the "adjuster", which

is used when setting the points "gap."

|

|

You can now install the new points base plate with

it's single retaining screw and place the new rocker

arm on it's pivot shaft: use the other cylinder's

points as a guide to make sure you have the rocker

arm placed correctly. Install the (2) little clips

for the rocker arm shaft. You can then install the

new condenser and secure the wire from the condenser,

the wire from the bottom of the coil (and the kill

switch wire, if you have one) under the little terminal

screw on the points base plate.

Replace the points and condenser for the other cylinder

and the magneto is now ready to be reinstalled on

the engine, but let's wait until we have the carb

work down before putting the mag back on. That will

give use a bit more room to work with.

One last comment before closing for this month:

you may have noticed (2) little red capsules that

resemble cyanide capsules that came with the tune-up

kit. Those are not to put you out of your misery if

you screw-up something. Now, you might actually want

to use them although I never have. More on the capsules

next time.

Later,

Max

click here for a

list of Columns by Max Wawrzyniak

|