NEMAH: The Birth of a Skiff

Part IV: Trimming

out the Hull and Fitting the Rig

by Tracy O'Brien

https://www.tracyobrien.com/

Part I

- Part II - Part

III

In Part

III of this series of articles on the

design and construction of the sharpie skiff, Nemah, we

went through the process of fabricating her plywood "shell/"

Here in the fourth and final part of this series we will

complete the hull, as well as fabricate and fit her sailing

rig.

A Logical Sequence

At

this point m the building process, the plywood shell is

structurally complete, but it's still quite flexible,

For this reason, we will leave the temporary spreaders

in place until the rail and thwart assemblies are fitted.

Even with the spreaders in place, the plywood side panels

are flexible enough that they can easily be forced out

of shape. To prevent any possible distortion of the finished

boat, we will need to hold the tops of the side panels

in a fair curve while fitting the forward and transom

bulkheads to the hull. This can be accomplished by fitting

the rubrails to the sides of the hull.

At

this point m the building process, the plywood shell is

structurally complete, but it's still quite flexible,

For this reason, we will leave the temporary spreaders

in place until the rail and thwart assemblies are fitted.

Even with the spreaders in place, the plywood side panels

are flexible enough that they can easily be forced out

of shape. To prevent any possible distortion of the finished

boat, we will need to hold the tops of the side panels

in a fair curve while fitting the forward and transom

bulkheads to the hull. This can be accomplished by fitting

the rubrails to the sides of the hull.

Before bonding the rubrails

in place, we can install the "riblets". They

are glued and fastened to the side panels with short bronze

ring nails driven through from the outside. The rubrails

are then glued up and fastened with bronze ring nails

driven through the side panels from the inside.

At this point, the breast

hook, oarlock blocks and quarter knees are also fitted.

The breast hook and quarter knees are glued and fastened

to the side panels with bronze or stainless steel screws

driven through the knee and into the transom, All screws

should be counter-bored and plugged. The oarlock blocks

are glued and clamped to the inside of the side panels;

no fasteners need be used.

Flotation

With the rubrails in place,

the structures that form the fore and aft flotation chambers

can be installed. We begin this process by fitting the

forward and aft bulkheads at their respective location

lines (which were marked on the side panels during layout).

These bulkheads are wired in place and fillet bonded to

the hull with 3/4" radius fillets on both sides.

After the fore and aft

bulkheads are in place, gluing strips are bonded to the

bulkheads, side panels, and the transom face to provide

bearing for the transom seat and forward deck. Prior to

closing up the forward flotation chamber, the towing eye

and its reinforcing block should be installed, as shown

in Figure 1.

Clockwise from upper left:

Figure 1. Bow eye is installed before the top to theflotation

chamber. Figure 2. A 3/4 " radius fillet is applied

to the inside corners formed by theseatfflotation tanks.

Figure 3. The mast step and mast partner. Note the drain

hole in the step.Figure 4. The after ends of the inwales

iaper into the topside panels. (click thumbnails to

enlarge)

The flotation chambers

can be foam filled or left empty, as desired. Coast Guard

regulations only require foam if motors larger than 2

horsepower are specified.

The

transom seat and forward deck (with its doubler in place)

are glued and fastened in place with bronze ring nails,

and then a 3/4" radius fillet is applied around their

entire perimeter (Figure 2), The aft upper edge of the

forward deck is bonded to the side panels with three layers

of fiberglass tape, as was mentioned in PartII

of this series. This helps distribute

the stresses developed by the sail rig to the rail

assembly.

The Inwales

After the forward deck

is bonded in place and its reinforcing tape is sanded

smooth, the inwales can be fitted. They are cut to length

and their aft ends are taper cut to join the side panels

prior to installation (Figure 4). They are glued and fastened

in place with 1-1/4" bronze or stainless steel screws

driven into the side panels aft, and into the inside faces

of the nblets in the mid section of the hull. The forward

ends of the inwales are fastened to the side panels from

station #152-1/2 forward, as shown in Figure 3.

The fore and aft rail

spacer blocks can now be glued and clamped in place (Figures

3).

Clockwise from upper left: Figure 5.

A simple template can be used to rout the hole for the

daggerboard case. Figure 6. The center thwart is notched

to clear the daggerboard. Figure 7. A taper jig can be

used to taper cut the spars on a table saw. Figure 8.

The butt of the sprit is drilled to accept the snotter.

(click thumbnails to enlarge)

The Daggerboard

Well

The daggerboard well consists

of two side panels, two spreader blocks, and two well

beams. It is assembled and trimmed to fit prior to installation.

The hole into which the well is fitted can be cut with

a saber saw or with a router fitted with a guide bushing,

as shown in Figure 5. Note how a temporary pattern is

assembled by stapling plywood strips to the hull bottom.

The advantage of this technique is that the finished opening

will require no further cleanup work.

The case is glued and

fastened to the bottom panel with two temporary screws

driven up into the ends of the well spreader blocks. Shims

are placed between the bottom edges of the well side panels

to prevent distortion, and then the well assembly is fillet

bonded and taped to the bottom panel.

Two thwart cleats are

fabricated from white oak and fastened to the riblets

at a point level with the top of the daggerboard well.

The thwart itself is fabricated from 3/4" mahogany

and is notched to provide clearance for the daggerboard,

as shown in Figure 6. The thwart is fastened to the daggerboard

well beams and the thwart cleats with bronze or stainless

steel screws.

Mast Attachments

The mast is fitted by

simply dropping it through the mast partner and fitting

the mast heel into the mast step, as shown in Figure 3.

The mast step is fabricated from 5/4" white oak and

is glued to both the bottom panel and the forward bulkhead.

It can be held in place with temporary screws driven up

through the bottom panel. (Note that the mast step is

fitted with a limber hole.) The mast partner is fabricated

from 1/2" or thicker marine or aircraft plywood and

is fastened to the forward deck with five #10 x 1-1/2"

stainless steel screws.

Finishing the

Hull

After the rail assembly

and flotation chambers are fitted, the temporary spreaders

can be removed and any remaining holes in the hull filled

with thickened epoxy. The tops of the rails should be

belt sanded and faired into the transom top, and so forth.

All trim work should be

given a coat of penetrating sealer. Some or all of the

trim can be left natural, as desired. On the prototype,

I opted to paint the majority of the hull, leaving only

the transom, rubrails, quarter knees, thwart assembly

and mast partner bright. All brightwork was finished with

gloss spar varnish. Single component urethane marine enamels

were used on all the painted surfaces. A small amount

of Grumbacher cobalt drier was added to both the varnish

and the enamels prior to application to speed drying,

as these finishes are often quite slow in drying when

applied over epoxy coated surfaces.

Fabricating the

Rig

Nemah's sailing rig consists

of five major components: a 12-foot mast, a 12-foot sprit,

a daggerboard, a rudder and tiller assembly, and an 80

square foot spritsail.

The mast is fabricated

from a 2" square by 12' long piece of clear fir or

spruce. The blank can be laminated from a number of pieces,

if required. The top 2 feet of the blank is tapered on

two adjacent faces to form a 1-1/2" square, when

viewed from the end (Figure 7). The blank is then chamfered

on all four corners to form an octagon. The heel is tapered

slightly all around to fit into the mast step, and a shallow

groove is cut around the mast head to provide a secure

place for lashing on the sail throat.

The sprit is fabricated

from a 1-1/2" square by 12' long piece of clear fir

or spruce. Each end of the blank is tapered on two adjacent

faces, with the taper cuts running out at 3 feet, leaving

a 1-1/4" square at each end. The sprit is then chamfered

on all four corners to produce an octagon, as with the

mast. The top 1" of the sprit is reduced to 3/4"

in diameter, leaving a shoulder to catch onto a rope loop

fitted to the peak of the sail. The butt end of the sprit

is drilled to accept the snotter, as shown in Figure 8.

Both mast and sprit are

given a coat of clear sealer and several coats of spar

varnish.

Above left: Figure 9.

Oak cleats, fastened to the quarter knees, are used to

turn the sheet back to the cockpit. Right: Figure 10.

The sail is lashed through a small pad eye to provide

tension on the luff. (click thumbnails to enlarge)

The daggerboard is cut

from 3/4" x 12" hard mahogany, and is fitted

with a cleat at its upper end. The lower leading edge

is given a 6" radius and the entire underwater profile

is faired off to a streamline section. The daggerboard

is held in place by a short length of shock cord, as shown

in Figure 6. The rudder can be cut from a length of 3/4"

x 10" hard mahogany, and is radiused and streamlined

as described above. It is fitted with bronze or stainless

steel pintles, and will require a keeper to prevent its

floating out of the gudgeons. The tiller is fabricated

from two lengths of 7/16" thick white oak, with a

13/16" mahogany core, the whole unit being epoxy

bonded together. The forward end of the tiller is tapered

to a comfortable thickness, and all edges are given a

1/4" radius. A 1/4" bronze or stainless steel

carriage bolt and self locking nut are used to assemble

the tiller to the rudder (Figure 9).

Daggerboard, rudder, and

tiller can all be finished bright or painted, at the builders

option.

A pair of oak cleats should

be fabricated and fastened to the quarter knees, also

shown in Figure 9. These provide a simple method of routing

the sheet from the quarters back into the cockpit.

Besides the bow eye, pintles

and gudgeons, and rowlock sockets, the only other hardware

requirements are a jam cleat to secure the snotter to

the spirit (Figure 8), and two small pad eyes, which attach

to the mast to prevent the sail lashing from riding up

the mast (Figure 10) and the snotter from sliding down

the mast,

Performance

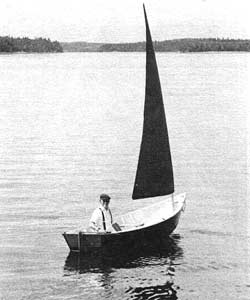

I have sailed Nemah in

a variety of conditions, from the light air of Olympia's

Boston Harbor, (where the rowing and sailing photos were

taken), to the gusty winds and choppy conditions of the

Ilwaco channel at the mouth of the Columbia river. On

Seattle's Lake Union she easily overtook a generously

canvassed traditional sloop while sailing close hauled

in a 6 to 8 knot breeze!

To windward, the loose

foot sets well, and actually is not much different than

a boomed sail, except that you can control the shape to

a greater degree with the loose foot. Downwind, the sail

bellies out, owning to the lack of a boom, but as the

sprit gives it shape at the peak, the sail performs quite

well, and doesn't tend to roll as much as most cat rigs

do on a run. The rig's low center of effort is quite noticeable;

even in a gust. I have been able to keep her on her feet

without having to sit up on the rail.

Under oars, Nemah is a

delight. Rowing solo, the hull trims a bit down at the

bow, which keeps her quiet and on track. With one or two

people in the stem, she is well balanced, moving easily

and going where she's pointed. I'm quite pleased at her

speed under oars; she carries well between strokes and

is not unduly hampered by the wind. I had an occasion

to row her dead to windward with board down and sail luffing

while in the Ilwaco channel, covering just under a mile

in 20 minutes.

At about 135 pounds without

her rig, she would take two adults to car top, but can

easily be handled by one person from a trailer or the

bed of a pickup. I've got the prototype on a trailer fabricated

from an imported trailer kit. I fitted it out with bunks

running across the width of the frame and bolted on a

10-foot tongue made of a nice piece of dry fir. The whole

towing package weighs under 300 pounds, and can be disconnected

from my mini pickup and rolled down to the water's edge

if no ramp is available.

Working out the design

of Nemah, and building and sailing the prototype has proven

to be both rewarding and enjoyable for me. I'm certain

that should you choose to build Nemah for yourself or

your family, you'll also find the building to be simple,

yet satisfying, and the sailing to be fun.

Plans and instructions

for Nemah

are $55 from Ken Hankinson and associates or from:

Tracy O'Brien Marine

Design

156 Bunker Creek Rd.

Chehalis, WA 98532

(360) 748.4089

fax (360) 740.0504

(tracy@tracyobrien.com)