A Skin-on-frame Pram with a Plywood Bottom

Designed by Dana Munkelt

Edited by Joe Millard

Drawings by Andrew Walters

Introduction:

"Robin" is a small skin-on-frame (SOF) pram design with a twist; a solid plywood floor. This worked out well in

a prototype at only 33 lbs., and these plans are for the New Improved Robin! Now Larger and Better!

Robin can be made from these plans with a length from 8' to 9', and a beam of 42"-45", and suits 2-3 adults in

sheltered waters. Weight should be 40-55 lbs., depending on size, robustness, and customization.

Robin is a good boat for rowing, not so good for sailing as the torque applied by a mast is hard on the light

structure. A very small outboard might work if the transom is reinforced, but this means more stuff to buy and

carry to the water.

I assume the builder has some experience building things, especially SOF boats, and some stitch and glue, or

a friend who does. This includes setting up building jigs/strongbacks, steam bending, fabric attachment,

epoxy and hot gluing.

Robin is a simple design and doesn't need any fancy work. You might build one of inexpensive materials

(underlayment ply is often waterproof enough - cut a small piece to test in a pan of hot water). Then after a

while build your own new and improved Robin.

There are two transom widths and two temporary mold widths (see dwgs 7-10). The intention was a pram

with a wider stern, but by mixing them up the boat can be wider (two wide transoms and molds), narrower

(two narrow transoms and molds), or double-ended.

Materials:

To begin with you need:

| Transoms |

Two pieces, approx. 1/4" ply, I built the first ones curved. (Drawings 9 & 10). |

| Temp molds |

Two pieces. (Drawings 7 & 8). |

| Stringers |

9'-10' x 3/4" x 3/8" - Eight pieces, fir, spruce or poplar. |

| Ribs |

12-14 pairs, 22"-29" x 3/4" x 5/16", approx. 7" spacing. Ash. |

| Ply floor |

8'-9' x 1/4" x 16". Scarf or glass tape to length for a longer boat. |

| Runners |

Two pieces. 8'-9' x 3/4" x 1". For outside bottom. |

| Outwales |

Two pieces. 9'-10' x 3/4" x 3/8" to 1/2". |

| Fabric |

8-12 oz. polyester or nylon. |

| Oarlock blocks |

12" x 3/4" x 1". Mount on top of outwales. |

| Knees |

Four pieces, for transoms, or a ply "foredeck", 4"-5" wide spanning the boat. |

| and ... |

Lots of clamps for steam bending. |

Construction:

Having made a choice of a set of molds and transoms, set them up right side up on the building frame/strongback over the ply bottom panel with about 5" rocker, a little less at the stern or if building a wider version (see dwg. 11). Choose a rake for the transoms, starting with about 25 degrees at the bow, and less at the stern. Adjust until you like it, and the stringers will still reach from end to end.

Bend the stringers into the notches in molds and transoms. Hold them in place with zip ties (drill holes in the molds), string, wire, or whatever at the the transoms. Get them settled into the notches, trimming the notches if needed. Then stitch the bottom panel to the transoms with wire stitches. Note that the stringers meet the transoms at an angle, and the notches should match that angle, and not be too deep.

Transom knees can be fitted now or later.

When all fits well, check that the boat is straight, level, and symmetrical, not twisted. Adjust if needed.

Now for the epoxy.

Mix some of your favorite brand, and brush into all joints: floor to transoms, stringers to transom. Not the molds! Then thicken resin to make a fillet at all joints, adding glass tape to the floor-to-transom joint. Small patches of glass can be added to the stringer-to-transom joints, too.

Ribs.

There are lots of articles about steam bending. Please read some. I built a steambox of 1·foam board and duct tape, then set it on horses with a PVC pipe leading down to a pan of water on a camp stove.

Ribs do not have to be full length. I used mostly 22"-29" half-ribs, with three full-span in the middle of the boat.

Mark rib locations first, bottom and top ends.

Lots of clamps are needed, zip ties can work for mild bends. I did the ribs in three batches, steaming several pairs in, gluing the next day, then steaming another batch.

Epoxy in a 10 oz. cartridge can be squeezed from a caulking gun, and makes this job much easier than mixing, spreading glue on each rib, clamping each rib, going to next rib … Just squeeze a perfectly mixed dab at each intersection, clamp and move on.

Inwale and spacers

Inwale 3/4"x 1/2" fitted to each outwale. Adding spacer blocks between stiffens the gunwale. These blocks can be 1" long pieces of leftover rib material glued on to each rib, or 3/4" thick blocks glued between ribs.

Seat risers and seats

Seats should be positioned about 8·below the top of the oarlocks, so the risers need to be located accordingly. Seats are a simple ply rectangle and a pair of rails approx. 3/4" x 1 1/4". Risers are also 3/4" x 1 1/4", top beveled to give a level surface for the seat rails. Risers should span 4-5 ribs. Seats can be clamped or lashed in place for launching, then moved a bit to find the best location for trim. Don't glue the oarlock blocks until the seat location is decided, then about 12" aft of the edge of the seat.

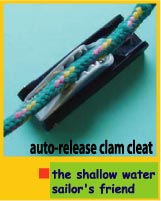

Fabric Fabric

Polyester or nylon, 8-12 oz. weight. Fabric does not extend across the floor panel, but is hot glued along the edges, overlapping about an inch. Round all edges and corners before fitting fabric, and seal endgrain. Don't paint before hot gluing or only the paint will be holding the fabric on!

Put several narrow beads of hot glue along the bottom, transom edges and outwale. Try to keep them fairly smooth. Fabric stores have a hot-melt tape which can also be used. Working from the middle of the boat towards the ends, use a clothes iron to press the fabric into the glue and smooth it out. Cover the iron with some foil to keep glue off. Practicing with some scrap fabric is a very good idea. Once the perimeter of the fabric is attached to both sides of the boat, use the iron to shrink out any remaining wrinkles. Not too many in a pram shape. Some stainless staples can be used along the outwale or transoms, if you don't trust glue there. Do the final trimming of the fabric with a hot knife or soldering iron after the fabric is positioned. Painting/sealing the fabric can be done with several materials. There are some good two-part urethanes, and I like latex-acrylic house paint. It's not too abrasion resistant, but is cheap, comes in lots of colors, and stays flexible.

Runners

Are full length, 3/4" x 1", put on after the fabric and are screwed down. I used flat head screws from the

outside thru the ply floor and into the rib ends. Screws could be driven from the inside.

Oars

About 6' long. Nothing fancy.

Click HERE to download free plans

See other designs by Andrew Walters

|

Fabric

Fabric