| A compilation of information

and tips from Rick Young, Steve Dashew, George Walner, and Bob

Gayle

Batteries - Depth of Discharge (DoD)

|

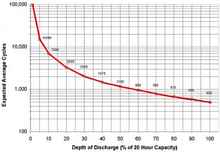

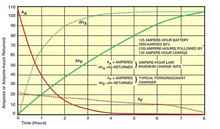

Figure 1 |

The relation between the cycle life of a battery and its DoD

is logarithmic as shown in Figure 1. In other words, the number

of cycles yielded by a battery goes up exponentially, the lower

the DoD. This holds for most cell chemistries, (eg. flooded, AGM,

and gel).

There are lessons here both for designers and users. By restricting

the DoD, the designer can improve the cycle life of the battery.

For example, look at the difference between 50% and 30% DoD -

the life cycle almost doubles. The important point to understand

here is that you can get longer life out of your bank of batteries

by either having more than the minimal daily capacity required,

or by topping the battery up before it becomes completely discharged.

The down side of installing greater battery capacity is the weight

and space they require, so typically a compromise is necessary.

Most people that write about this subject will tell you that a

cruiser should not allow their batteries to drop below a 50% DoD

because the life expectancy will diminish rapidly, which is true.

They'll also tell you that you shouldn't charge beyond 80%, because

the cost of charging is greater, (actually it takes longer), and

thus will offer diminishing returns and that as it turns out is

less true.

How to Kill Your Batteries

"In the industry it is estimated that about 85% of lead-acid

batteries die prematurely by being under charged. For example,

if you fail to reach a proper minimum acceptance voltage for a

sufficiently long period of time the battery continually degrades

and looses capacity on repetitive cycles. This is true for flooded-cell,

AGM, and gel cells; that are killed by permanent sulphation due

to undercharging, and includes standing for long periods short

of a full charge." "Most cruising boats are short of

a full charge, typically only charging to 80%, and most cruisers

have little knowledge of proper care for their batteries. I suspect

that the number for cruisers killing their batteries exceeds 85%

under repetitive undercharged cycling." - Rick Young

There is a simple reason most cruisers stop charging when the

batteries at 80% capacity. Most charging is done with the propulsion

engine's alternator, a separate generator or shore power, supplemented

by wind or solar. Since marina space is more expensive than fuel

most cruisers anchor out and use one or more of the other alternatives

to generate power. The ability of a battery bank to accept current

varies depending on its state of charge, after 80% a battery's

ability to accept current (amperage) decreases and slows down

dramatically; so getting that last 20% of charge takes hours,

which if you're using an engine or generator becomes a noisy,

expensive and inefficient use of fuel.

Battery Monitoring

A good battery monitor is the cornerstone of a good charging

system; it will measure kW-hours in addition to Amp-hours consumed

and returned. This makes monitoring the battery bank and maintaining

proper charge much easier.

Ideally you would perform a live test operating as you might

over a 24 hr discharge time and measure exactly how much energy

is used, but an estimate can be used to roughly determine the

size the battery bank and determine the space to accommodate it

and determine hwo the weight will effect trim. Knowing the kW-hour

number one can then decide whether or not to go with flooded,

AGM or Gel-cell batteries (Amp-hour numbers will not tell you

that because the three types of batteries having all the same

Amp-hour rating, will not have the same kW-hour rating). Those

cruisers using non flooded-cell constructed batteries, where you

are not able to replenish lost water require

a monitor such as the Link 10 or Link 1000 for the longevity of

the batteries. A real battery monitor is one that not only shows

the usual Amp-hour status but actually measures true energy into

and out of a battery bank (kW hours) and one whose measurements

are stable for long periods of time and over a wide temperature

range. It should be capable of displaying battery status in a

simple, easily understood way that itself doesn't drain the battery

bank. Dollar for dollar the best real battery monitor is the Link

10 or the Link 1000 ($250). They display battery status using

LEDs. The LEDs are in a row of green followed by yellow and finally

red LEDs that act like a "gas gauge" for your batteries.

The milliamp load of the LEDs is far less than a digital or analog

meter, though a digital meter is integral to the monitor, switch

selectable for different displays, but remains off until desired.

The Link 10 has an optional battery temperature sensor (otherwise

you enter the ambient temperature manually). The Link 1000 is

temperature sensor "ready" yet I do not know if Xantrex

is making the temperature sensor for both of these products, since

it wasn't originally designed by them.

The Amp-Hour Law and 3–Stage Charging

| Figure 2. The Current Acceptance and Charge

State of the Amp-hour Law 2 Also graphed is the 8 hour charge

cycle for a Ferroresonant (AC)Charger |

|

"As good as Nigel Calder is he is wrong regarding the

maximum charge rate not exceeding 25% of battery capacity for

flooded cells and 33% for AGM, about how fast and how much current,

as well as how much lead-acid batteries can safely charge accept."

"A charging current equal to the value of the number of Amp-hours

"missing" from the battery will not excessively gas

or heat the battery. This is the "Amphour Law" which

was proposed many years ago by G. W. Vinal in "Storage Batteries",

before the technology existed to implement it (1920's). The charge

curve following this "law" forms an exponential curve

of E, with an ever decreasing curve of charge current - Rick

Young

The Amp-hour Law is shown in Figure 2. Notice that the state

of charge of a battery being charged to the Amp-hour Law (AHA

the dotted green line) mirrors the battery's charge acceptance

(AA the solid red line)

in that the current lost roughly matches the current supplied.

For example, a 450Ah battery bank discharged to 50% can accept

225A current initially, which then tapers down as the battery

charges. Following this curve you can safely recharge a 100% discharged

battery in about 3½ hours (AGM and gel cell) to just under

4 hours (flooded-cell) batteries. All lead-acid batteries designed

to deliver heavy discharge currents, like those you need for cruising,

will be capable of following the Amp-hour Law.

Now compare the Amp-Hour charging curve to the charge curve of

a typical ferroresonant (AC) charger (AF

the solid green line compared to AHA

). It takes 8 hours for the AC charger to do what Amp-hour charging

does in half the time. If you're using shore power to do this

it's no big deal, power is abundant and available - it's only

the marina space attached to the power cord that's expensive.

Anyone contemplating using an AC generator to provide power for

battery charging however should realize they're accepting the

chargers 8 hour charge cycle not the generator's output. You'll

be spending a lot of time running your generator unless you look

for a 3-step charger, with as high an amperage as your generator

will support.

3-step regulators were the first attempt to achieve a charge

curve approximating the Amp-hour law. To approximate Amp-hour

charging requires more than just a fancy regulator, you also need

a sufficiently large bulk charging source to replace those missing

amps. 3-stage charging is roughly divided into bulk, absorption,

and float stages. Bulk charging handles all but approximately

the last 20% of the batteries charge state. . Bulk charging is

dependent on availability of sufficient charge current and the

batteries ability to accept that current; the closer the amperage

of the charge source "matches" the amperage lost, the

less time bulk charging will take. In Figure 2, the first 1½

hour of bulk charging, restores about 80% of the battery's total

amperage capacity. The time this takes is largely dependent on

the amperage your charge source can provide. For the high current

demands of bulk charging one of the best alternatives is a high

output alternator on your propulsion engine; the engine is already

there and has an alternator so little additional expense is involved

in improving this element of the charging system. In any case,

you'll also need this charge source to meet your energy demands

while on passage.

As battery voltage approaches the charging voltage, the charging

current required begins to rapidly decrease, and the state-of-charge

increases much more slowly. This is the absorption phase of the

charge cycle, and note that the solid red line indicating current

acceptance drops from 20% to 5% of the battery's capacity. About

4 hours into Amp-hour charging this fully discharged battery,

the number of ampere-hours returned to the battery is back to

100% of its rated capacity. However, the battery will still accept

additional amperage up to about 105% at a greatly diminished current.

This is the so-called "trickle charge" of the float

charge cycle. Beyond about 105% virtually all amp-hours supplied

to the battery are consumed in electrolysis and in heating the

electrolyte.

"All types of lead-acid batteries, including AGM and

gel cell, when subjected to Amp-hour-law charging almost never

need equalization." - Rick Young

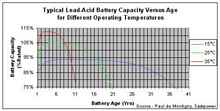

Temperature Effects

|

Figure 3 |

The shelf life and charge retention depend on the self discharge

rate and self discharge is the result of unwanted chemical reactions

in the cell. Chemical reactions internal to the battery are driven

either by voltage or temperature. The hotter the battery, the

faster chemical reactions will occur (see Figure 3). High temperatures

can thus provide increased performance, but at the same time the

rate of the unwanted chemical reactions will increase too resulting

in a corresponding loss of battery life. Similarly, adverse chemical

reactions such as passivation of the electrodes, corrosion and

gassing are common causes of reduced cycle life. Temperature therefore

affects both the shelf life and the cycle life as well as charge

retention since they are all due to chemical reactions.

Maintenance - Adding Water to Flooded Cell Batteries

The electrolyte in lead acid batteries is a dilute solution of

25% sulpheric acid in water. As the lead-acid cell reaches a full

state of charge, the water in the electrolyte is broken down into

hydrogen and oxygen gasses by the recharging current. These gasses,

along with some acid, escape from the vent on the top of each

cell. This process, called "gassing", accounts for the

water lost from the cells. High temperatures (90oF), high rates

of recharge, and elevated voltage limits (2.44vdc per cell) all

increase the amount of gassing that can occur during the recharging

process. If all the cells in a lead-acid battery are to be fully

charged, then a certain amount of gassing will take place. It's

up to us to deal with this situation. We add distilled water to

the cells to make up for the water hydrolyzed into hydrogen and

oxygen.

Never top off the water

of cells that aren't fully charged. This presents a dilemma

to cruisers who often only charge to 80% of the battery's capacity.

There is a product on the market that constantly maintains

water level in the cells of the battery from a reservoir, and

touts its convenience for the user. Really it's just

a convenient way to shorten battery life, because overfilling

with water will inevitably lead to acid spills and loss of electrolyte

when you do fully charge.

Ideally we would like to capture any water/acid that boils off

the cells, condense it and return it directly to the same cell,

as this would keep the cell chemistry as stable as possible over

time under all conditions. There are products that help do that.

Water Miser caps and Hydrocaps replace the regular cell vent

cap on a battery. When the cell is gassing, the hydrogen and oxygen

gasses are vented into the cap, which captures and condenses the

gases returning the recombined water to the cell. Hydrocaps use

a catalyst to recombine hydrogen and oxygen gas back into pure

water. (A chemical catalyst is a substance which facilitates a

chemical reaction in other substances, in this case hydrogen and

oxygen, without actually participating or being consumed in that

reaction.) The resultant water is then dripped back into the cell.

This reduces both the danger posed by out gassing explosive hydrogen

and the frequency of replenishing water in the cells. The catalyst

used in Hydrocaps is effective for about 8-9 years before prolonged

acid exposure causes the catalyst to deteriorate requiring replacement.

Water Misers trap water and acid vapor reducing water loss by

50-80%, Hydrocaps recombine the gasses and reduce water loss by

90%. Hydrocaps do get hot when the charging cycle causes out-gassing,

heat being a by product of the chemical reaction taking place.

Hydrocaps should be removed when equalizing, but proper equalization

needs to take place with abundant shorepower and with the proper

test equipment. Actually improving your charging system may almost

eliminate the need for equalization charging.

"We've been using Hydrocaps for 15 years to reduce battery

water consumption and help keep the battery tops and terminals

clean of acid buildup. This will cut down on water consumption

and gas emission." - Steve Dashew

In an independent test of an off-grid home solar system; a battery

bank of Trojan L-16s had their caps changed to Hydrocaps and after

2 months operation required no additional water, this despite

previously consuming 1.5 gallons in a similar period without Hydrocaps,

Off-grid homeowners, RV owners, and cruisers that use Hydrocaps

report only adding water annually or semi-annually when they clean

the tops of the batteries of any acid deposits, dirt and dust.

This is a significant improvement that avoids getting you in trouble

with your maintenance regimen.

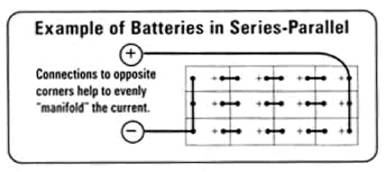

Connecting Your Battery Bank - Avoid Multiple Parallel

Strings

The ideal battery bank is the simplest, consisting of a single

series of cells, sized in amperage capacity for the job, with

power taken off at each end, (eg. negative on one end and positive

on the other end). Higher capacity batteries tend to have thicker

plates, and therefore greater longevity too. Having fewer cells

reduces the chance of randomly occurring defects, and reduces

charge equalization problems within cells. Suppose for example,

that you require a 600 amp-hour bank. Since the best price per

Ah available in the battery market is the flooded cell golf cart

battery (6v, 200-225 Ah) most cruisers will arrange their battery

bank in a series/parallel string to get 12volts at the desired

amperage. You can approximate the 600 amps by using 3 series/parallel

strings of T-105 golf-cart batteries (225 Ah each) as shown in

Figure 4, or 2 series/parallel strings of the larger L-16 deep

cycle batteries (390 Ah each) or by a single series string of

large 2v, industrial traction batteries of 600 Ah capacity per

cell.

Using parallel strings invites problems in maintaining equalization

within the battery bank unless they're connected correctly. Under

no circumstances is it advisable to install more than three parallel

battery strings. The resulting bank will tend to

lose its equalization, resulting in accelerated failure of any

weak cells. Weak cells will be difficult to detect because they

will "steal" from the surrounding cells, and the system

will suffer as a whole and will cost you more in the long run.

Here are some precautions to take when wiring two or more strings

of batteries in series/parallel:

- The goal is to maintain all of the cells at an equal state

of charge. Cells that tend to receive less charge are likely

to fail prematurely. This can take years off of the effective

life of the battery bank. A fraction of an ohm of added resistance

in one battery string can reduce the life of the entire string

so measure it and juggle batteries and/or cable lengths to get

them as close to equal as possible.

- Connect the two main cables to opposite corners of the battery

bank, and maintain symmetry in wire size and lengths. This will

help to distribute current evenly through the bank.

- Arrange batteries to maintain even temperature distribution

throughout the bank. Avoid uneven exposure to heat sources.

Leave at least 1/2 inch of air space around each battery, to

promote even cooling.

- Apply a finish charge at least every 3 weeks (bring every

cell to 100%

charge).

Preventing Corrosion

In flooded battery installations, corrosion of terminals and

cables is a nuisance that causes resistance and potential hazards.

Once corrosion gets hold, it is hard to stop, but luckily it is

easy to prevent. Apply a non-hardening sealant to all of the metal

parts of the terminals before assembly. Completely coat the battery

terminals, the wire lugs, and the nuts and bolts individually.

A sealant applied after assembly will not reach all around every

junction. Voids will remain, acid spatter will enter, and corrosion

will begin as soon as your installation is finished.

Special compounds are sold to protect terminals, but you can

have perfectly good results using common petroleum jelly (Vaseline),

which will not inhibit electrical contact. Apply a thin coating

with your fingers, and it won't look sloppy. If a wire is exposed

at a terminal lug, it should be sealed airtight, using either

adhesive-lined heat-shrink tubing or submersible rubber splice

tape. You can also seal an end of stranded wire by warming it

gently, and dipping it in the petroleum jelly to liquefy, and

wick it into the wire.

It helps to put the batteries over a floor drain, or in a space

without a floor, so that they can be rinsed with water easily.

Washing the battery tops semi-annually will remove accumulated

moisture, acid spatter, and dust. This will further reduce corrosion,

and will prevent stray currents from stealing energy. Batteries

installed using these simple protective techniques show very little

corrosion, even after 10 years without terminal cleaning.

Energy Audit - Efficiency First

"Very often I have calculated battery system "size"

to be in the region of 400 Amp-hours for a 40' cruising yacht,

but only if the customer would change the fridge to a high-efficiency

unit." - Rick Young

The first design parameter is to find is your daily amp requirements

by making a preliminary energy audit of at anchor and on-passage

needs. (It's not unusual BTW for on-passage energy needs to exceed

those at anchor, because you'll be using GPS, electronic charting,

AIS, and autopilots etc. on-passage) Initial investigation should

reveal where you could use more efficient equipment, like compact

fluorescents, evaporator plate DC refrigeration, LED anchor lights,

etc. The approximate number of kW-hours that may be consumed over

24 hrs provides the parameters for sizing the battery bank.

AC appliances consume enormous amounts of battery power (110v

x amperage x hours of operation), and need to run off inefficient

inverters. Replace AC appliances where DC alternatives are available.

Try to limit the AC appliances operated by inverter to those that

run for short time periods, (eg. coffee grinders, hand blenders,

microwave ovens). Look at alternatives (propane or diesel) to

electric appliances for heating water or cooking which demand

high current for long periods, or plan on powering them directly

with a small AC generator when they're in use.

A spendthrift approach to efficiency will quickly drain even

a large battery bank, forcing you to depend on shorepower or running

a separate generator for long periods. From your daily energy

needs you can begin to design a charging system that will return

that energy to your battery bank.

Battery Decisions - 12 or 24 Volts

If you're building a boat and don't have an existing electrical

system installed this is an important decision that will effect

your wire sizing and selection of equipment. If you have an existing

boat and decide to switch to 24 volts you probably don't need

to rewire since your existing wiring will be carrying less amperage,

but you'll probably want to change out much of the DC electrical

equipment to 24 vdc. Some appliances aren't available in 24 volts,

but lighting, fans and pumps are and will have the same power

demands, but at 24volts require about half the amperage. Often

24vdc equipment is a bit more expensive, sometimes it isn't.

Power in watts = Volts X Amps

12v x 10A = 24v x 5A

Many cruisers base their decision to use a 24vdc system on the

use of an electric windlass or bowthruster, because the high current

these demand requires very heavy gauge wire on a long run from

the battery to the front of the boat. 24volts halves the amperage

and reduces the wire gauge required. I would suggest that there

are other good, even better reasons for using a 24 vdc system

on today's boats. These have more to do with the nature of the

marine market itself, and the increasing use of electronic equipment

on board.

"There are but two ways to build truly reliable electronics:

large volume or high cost, either of which are challenging in

the small, fragmented marine world." - George Walner,

electrical engineer and designer/owner of 'Electra'

The marine market is really tiny especially compared to the automotive

and truck markets, where R&D costs can be spread over millions

of units or where volume and the demand for reliability have improved

the product. Always look for alternatives from larger more demanding

markets before buying anything with the word "marine"

on it.

The marine market is really tiny especially compared to the automotive

and truck markets, where R&D costs can be spread over millions

of units or where volume and the demand for reliability have improved

the product. Always look for alternatives

from larger more demanding markets before buying anything with

the word "marine" on it.

Here are my reasons for deciding on a 24vdc system:

- Electronic equipment is very sensitive to voltage fluctuations,

which are typical in a nominal 12 volt battery bank, (voltage

varies from about. 11.2-14.4 volts). The military is dependent

on an extensive array of on-board electronic equipment in their

vehicles and have standardized on 24v electrical systems. To

power electronic equipment they use DC-DC converters, that can

withstand extremely harsh environments, to step down from 24v

to 12v so any voltage fluctuations at the battery bank can be

virtually eliminated at the 12v electronics. Since the DoD paid

for the R&D and obtains this equipment from COTS (common

off the shelf) contracts, the result is reliable cost effective

commercially available converters. (3)

- Telecommunications systems that are off-grid, (ie. antenna

and cell-phone towers), are typically based on either 24 or

48vdc systems. DC to AC inverters designed for use in cell phone

towers are rugged, modular (combining to supply higher amperage),

hot swappable and very reliable. The cell phone companies that

operate them demand high reliablity. (3)

- Generating DC electricity using a high output alternator on

the propulsion engine is often the cheapest and most cost effective

charging source. We can dramatically improve the efficiency

of the typical truck alternator by operating it at 24 volts.

It turns out that using 12 volts places an efficiency limit

of about 50% on the typical "claw-pole" automotive

alternator. This was considered acceptable in the 60's when

fuel prices were low and the switch to alternators was motivated

by the need to generate higher currents at idle to power accessories.

Running a 12 volt alternator at 24 volts can improve its efficiency

dramatically. (More about this when I cover alternators and

how they work.)

Battery Bank Sizing – Making a Compromise

Steve Dashew is very smart and he's been working on and refining

solutions to charging systems on cruising boats for a long time.

I was always intrigued by his choice of "traction batteries"

(used in forklifts) and the high amperage he typically selected

for his battery banks, (800Ah on Beowolf, 1400Ah on Windhorse,

and recently 1200Ah on the FPB64). This isn't just overkill; there

is logic at work here. Traction batteries unlike golf cart batteries

are designed to be discharged regularly to 20% rather than 50%

of their capacity, giving him an extra 30% of capacity available

for use should he want it. (In other words, this increases his

flexibility in staying longer in an anchorage

without charging.)

Dashew's battery banks are composed of individual 2 volt cells,

which can be used to create a simple series string; that is more

reliable than a series/parallel arrangement. Though very heavy

in total, and quite tall, each 2v cell is separate, so lifting

a single cell is within the capability of one or two fit men (depending

on size). The cells are available in a variety of amperages so

he selects the size to equal his desired amperage for the entire

battery bank. Like off-grid solar powered homes, he sizes his

battery bank to power the boat for multiple days. On the FPB64

he has 80% of 1200 Ah available (960 Ah) or enough for a daily

load of 320 Ah for 3 days. He plans on powering to a different

anchorage or running his generator every third day to recharge

his batteries. The generator also provides power for electric

cooking and doing laundry along with battery charging. (Some small

generators can drive a separate truck alternator for battery charging.)

To recharge his batteries when powering, Dashew uses twin nominal

150A 24v alternators with electronic controllers to equally divide

the output needs. His is the kind of compromise you almost never

read about in boating magazines, but makes perfect sense.

I have to admit being puzzled by the fact he didn't use the large

roof area of the FPB series to mount solar panels, which could

provide the area to supply some of his daily needs, toping off

the batteries regularly at absorption and float current levels.

That would make it very much like an off-grid solar home with

generator back-up. His boats have the space for a large battery

bank and he mounts them so as to balance the boat's trim. I have

to admit being puzzled by the fact he didn't use the large roof

area of the FPB series to mount solar panels, which could provide

the area to supply some of his daily needs, toping off the batteries

regularly at absorption and float current levels. That would make

it very much like an off-grid solar home with generator back-up.

His boats have the space for a large battery bank and he mounts

them so as to balance the boat's trim.

You're probably wondering what this high dollar example has to

do with the much smaller, less demanding and hopefully cheaper

electrical system on your boat. It is illustrative of how you

can make compromises in electrical and charging system design

to achieve a particular cruising goal. In Dashew's case, he wants

his average 3-day stay in an anchorage to be largely free of the

noise and attention demands of a generator, but doesn't want to

give up much in creature comforts, including a washer/dryer and

DC air conditioning, so he developed a compromise to suit.

Let's use Rick Young's typical 400 Ah 12v battery bank on an

efficient 40' cruising boat, to look at an alternative compromise.

Figuring that the bank is sized for a daily load of about ¼

the size of its capacity (which is typical) it suggests about

100-150 Ah daily load @ 12 volts. Let's work these hypothetical

numbers to try to achieve a different compromise. We'll start

by switching to a 24 volt system, so our daily load will change

to about 50-75 Ah. Ideally, we'd like to restore much of that

load using solar power, but we know we'll never have the area

available for bulk charging; for that we'll rely on a high output

engine driven alternator which we'll need anyway on passages to

recharge the batteries.

What if we increased the Ah capacity of our battery bank so that

our daily load could be supplied by solar panels at absorption

cycle current levels. That would reduce our solar charging system

to about 20% of the battery banks capacity. What size bank would

we need?

75Ah / 0.20 = 375 Ah

Let's use a battery bank of L-16s (390Ah). 4 L-16s in a series

string is taller and heavier than T-105's but has about the same

footprint. How many days can we operate without charging?

390Ah * 0.50 DoD / 75Ah per day = 2.6 or about

2½ days

Suppose we change to 420Ah 2v traction batteries. Will their

ability to handle an 80% DoD extend our days without charging?

420Ah * 0.80 DoD / 75Ah per day = 4½ days

We still have two unanswered questions:

1. Can we design a bulk charging system that can provide the

200-320 Ah needed to bring a 400 Ah battery bank up from 50-80%

DoD?

2. Can we fit a solar array on the boat to provide about 75Ah@24volts?

Let's try to answer those questions in that order alternators

first.

Alternators and Regulators

How alternators work - The typical automotive

"claw-pole" alternator uses a magnetic rotor (turning

element) consisting of either permanent magnets or more commonly

electromagnets with a field current in their windings. A stator

is placed around the spinning rotor. Within limits, the stator

wiring determines the amperage output of the alternator. An alternator

generates 3-phase alternating current (AC). The AC current comes

off in three legs and then a group of 6 diodes (rectifier) are

used to convert the AC to DC. "P" type alternators use

electromagnets in the rotor and have two field brushes that pass

the field current to the spinning rotors. The voltage regulator

monitors the battery voltage and varies the field current to alter

the amount of current and voltage supplied to the battery.

|

Left: Rotor with copper slip rings for brushes

Right: Stator with 3 Phase Output |

The USCG has seen fit to certify as "marine" only brushless

permanent magnet alternators, to avoid sparking and fire on gasoline

powered boats. Diesel engines don't have fumes that ignite and

so non-marine alternators work fine; indeed to achieve an Amp-hour

or 3-step charging regime requires altering or interrupting the

field current and is the simplest way to control the output of

the alternator. Dropping the "marine" designation also

allows us to take advantage of the economies of scale permitted

by the truck market.

Truck alternators aren't designed to charge banks of deeply discharged

batteries. Instead, they're designed to maintain them against

a given load. Take an emergency vehicle, as an example. It might

have 100 amps of load with various devices in operation, with

the engine idling. Supplying the current to recharge after starting

isn't demanding, so the battery never really gets deeply discharged

and the alternator loafs along, with the field current cycling

on and off, which helps keep the alternator cool. In fact the

voltage regulator is built into automotive and truck alternators,

and actually monitors alternator temperature to keep them cool

since diode failure from heat is the #1 cause of alternator failure.

The internal regulator that comes with the alternator can't do

3-step charging, so it gets tossed out in our application.

Now come on board a boat with a large battery bank and an intermittent

charging regimen. When the alternator starts up, it has to go

to full output, sometimes for hours on end, to get the batteries

back up to their charged state. This means the current flowing

to the alternator field is on constantly - what is called full

field operation. There is no chance for the alternator to cool

down, except via the air being pulled through it by its own fan.

(Tip - Always match the fan assembly to the direction your engine

turns, though bi-directional fans are available for many alternators

they're much less efficient than a directional fan.)

To meet the current needs for bulk charging on a cruising boat,

a high output alternator will spend much of it's time in full

field operation. Two small frame high output alternators (90-100A)

will not be as reliable or as efficient as one 160A large frame

alternator. The large frame truck alternator has much more volume

with which to accommodate magnetic flux saturation of the field,

better cooling and bearings that are about 4 times "stronger"

than those of small frame alternators; all these advantages in

a package only 1.5 inch larger in diameter.

Alternator Heat Management - The majority of

the heat from an alternator comes from the rectifier diodes, which

convert the alternator's AC power to DC. Most alternators draw

air from back to front. Unfortunately, the air behind the alternator

in most installations is typically beside the exhaust manifold

of the engine - the hottest place in the engine compartment. Alternators

with internal rectifiers can get so hot, you could fry an egg

on them, and many can get hot enough to melt the epoxy insulation

on the stator wiring when operated at fullfield current.

| This is the rectifier board on Steve Dashew's

FPB64, taken from his Setsail website. It shows the two remote

mounted (fan cooled) rectifiers for the Electrodyne alternators.

These are installed remotely outside the engine room. The

Smart voltage regulator is mounted between the rectifiers. |

|

Heat reduces output, and shortens the life of the alternator.

Removing the rectifier diodes from the alternator body, and putting

them in a fan-cooled box removes the heat source from the alternator

body and the diodes from the hot engine compartment, greatly increasing

the durability and life of both. There are kits available

to do this, or you can just remove the alternators

rectifier and replace it with an aluminum spacer (with holes for

cooling) if necesssary, and mount the rectifier in a fan-cooled

enclosure outside the hot engine room.

|

Here's a photo from Dashew's FPB 64. Instead

of the solid belt guards that come with the Luggar engine,

they've built expanded metal guards in front of the engine

. |

|

and around and in front of the belt of the alternator

that permit cooling air flow |

We thus far have stripped our truck alternator of everything

but the rotor, stator and field brushes. If you buy a new high

output alternator, the rectifier and regulator are often mounted

internally or in some cases on the back of the alternator. An

even cheaper alternative would be to buy an alternator core from

a wrecking yard, clean it up, strip out the rectifier, toss the

regulator, replace the brushes and bearings and any defective

parts (if necessary). Warning

- It is very important when stripping an alternator of these electrical

parts to make sure that all electrical connections are well fastened,

free from contact with the moving rotor and insulated from the

alternator casing. This is particularly true when removing the

rectifier diodes. An alternator repair shop should be capable

of performing this for you if you explain what you intend to do

and why.

Alternator Selection - About the most amperage

you can get reliably from a12vdc alternator is 160A, which makes

the Leece-Neville 110-555 "triple nickels" one of the

better off-the-shelf alternatives on the market. (Leece-Neville

was purchased by Prestolite who changed the part no. to 8LHA2070JHO

for a typical12/6 mounting lug arrangement or 8HLA2070PHO for

a pad mount.) These are frequently used by the manufacturers of

motorcoachs and large RVs. The large frame Delco CS144 140A alternator

was used for many years in delivery vans and ambulances and has

a good reputation also.

DC refrigeration systems often trigger the need for larger battery

banks. Many cruisers turn to generators as a charge source, but

as we've seen selecting a typical AC charger can double the time

to charge over a 3-step charging regime. Most AC chargers are

made to be connected to shorepower so often provide much lower

amperage than a high output alternator can, which also increases

the time to charge. Running a generator for long periods in most

anchorages certainly won't make many friends among your fellow

boaters.

If you intend to recharge a large battery bank you can resign

yourself to longer charge times or use some ingenuity to come

up with a better solution. One option is to temporarily split

the typical series/parallel battery bank into two independent

12v banks for charging and thus cut the current demand of each

bank by half. A split charging regime can work especially well

when using two battery chargers with a small generator for power,

as long as the charger and battery split are completely independent.

Another alternative is to mount twin alternators on the engine.

Boats with twin engines do this using an electronic controller

to balance the alternators output, like Ample Power's Dual Alternator

Controller

(DAC). (If you attach both alternators without an electronic controller

to balance the load, one alternator will work at full output and

the other will loaf along - it just doesn't work.) Where fuel

consumption and engine operating hours are important this doubling

of available charge current can keep the time for bulk charging

short and still do it with truck alternators (cheap).

Another option, particularly for people building their boat,

is to decide to install a 24vdc system. Bob Gayle wrote a white

paper4 about improving the efficiency of a typical truck alternator

and thus its power output. He switched a Leece-Neville110-555

alternator to charge at 28.8vdc. The measured output for this

alternator were 130A @ 14.2v (1.85 kW) at 3400 rpm. With the regulator

fooled into using a 28.8 volt setpoint for output, the alternator

produced the same 130A @ 28.8v (3.74kW) at 3400 rpm at full field

current, almost doubling its power output just by allowing it

to operate at the higher voltage. No rewinding was needed since

the windings are running the same current. Bob used an old 12v

Balmar regulator monitoring voltage from the middle of the battery

bank, so the regulator thought the alternator was generating 14.4v;

instead of the actual 28.8 volts being delivered across the entire

battery bank, (this works easier using a regulator that allows

a 28.8v setpoint).

Such a configuration can easily provide the bulk charging for

a 24v 225Ah bank, or even a 24v 390Ah bank composed of L-16 batteries.

Two alternators with the Next Step regulator and Dual Alternator

Controller can charge even large traction battery banks. We know

this because Dashew uses a similar arrangement to charge the 1200

Ah bank on the FPB64. The difference is just one of Dashew's two

Electrodyne alternators retails for $1,242, while 2 L-N "triple

nickels", the Next Step regulator and DAC would retail at

$954 and you can find "triple nickels" for a lot less.

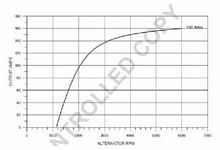

Selecting the Pulley Ratio - The pulley ratio

is determined by the following equation:

Pulley ratio = Crankshaft Pulley diameter / Alternator Pulley

diameter

Notice that the output curve in Figure 5 varies with speed in

RPM and that to run the alternator near its peak output requires

a shaft speed of 3500-4000 RPM which is much faster than most

diesel engines will turn at cruising speed. The cut-in speed for

this alternator is 1000 rpm for 12v, (2000 rpm if run at 24v),

and the manufacturer has an 8000 rpm continuous rating for this

alternator.

For example: I've determined that the cruising speed of the Isuzu

4LE2 engine should be about 1800 rpm. The Isuzu's maximum speed

is 3000 rpm. The alternator needs to reach the cut-in speed of

1000 rpm for 12v (2000 rpm for 24v) at an idle speed of 800-900

rpm for a ratio of 1.25:1 or greater (2.5 to 2.67:1 for 24v).

I would want to turn the alternator at 3400-4500 rpm alternator

speed at 1800 engine rpm - a pulley ratio of 1.88:1 for 12v (2.5:1

for 24v). At 3000 rpm the alternator would be turning 5640 rpm

(7500 rpm for 24v), still below its 8000 rpm limit.

The power requirements of big alternators put big strains on

the drive belts, alternator brackets, and pulley tensioning devices.

Add in the power pulses which are inherent in all diesel engines,

and it takes muscular engineering for all of this gear to stand

up over time. Switch to dual V belts is mandatory, or using "poly-V"

or ribbed belts and a serpentine drive is a better idea that can

also reduce tension requirements. They're more reliable and better

at power transmission.

| Figure 5 Prestolite 8LHA2070 / Leece Neville

110-555 |

|

Alternator Mounts Should be Made in Steel -

Should you decide to add a second alternator you'll need to make

mounts. Steel is used by every engine manufacturer to build alternator

mounts for two reasons:

- Steel has vibration resistance that provides years of trouble

free service.

- Steel matches the engine’s galvanic voltage potential,

thus preventing

rust. Dissimilar metals and should not be mixed in a marine

environment.

Delco makes universal welding brackets for alternators, (2"

mount - unplated for welding). It should go without saying that

you should measure your alternators mounts and compare them to

the brackets before buying them. These can be welded to a custom

supplied engine bracket, and the heavy duty curved belt tension

extension bracket, (3/8" thick x 1-1/4" wide, unplated).

|

Left: Delco Part # A300 $17

Right: Delco Part # A220 $29 |

Finding the HP and Torque Required for a High Output

Alternator

130 amps (@3400 rpm) x 14.4 volts = 1872 watts

1872 watts / 745.7 watts/hp = 2.5 so figure 3 hp

3 hp x (5252 / 900 rpm) = 17.5 ft./lbs.

The same current @ 28.8v or twin alternators would take 2.5hp

*2 or 5hp

Voltage Regulator - During the bulk charge step,

the battery can accept most of the alternator current and convert

it back to available capacity. Once the battery nears a full charge,

excess charge current becomes heat. Small at first, the heat begins

to accumulate in the mass of the lead plates. As the heat accumulates,

temperature of the battery begins to rise. The current through

the battery begins to double for every 18oF increase in temperature.

That means more power is dissipated in the battery which means

more heat is generated, which means more current flows, which

means more heat - all leading to thermal runaway.

If you're lucky you won't be looking at the battery when the caps

blow off with acid following. To avoid this absolutely requires

a voltage regulator to control the alternators output.

The voltage regulator monitors the battery's voltage; if the

battery needs more power the voltage regulator changes the field

current to the rotor coils. If the regulator senses a large discrepancy

between the battery voltage and its setpoint, it sends maximum

power to the rotor. If the regulator senses a small need at the

battery it will send minimal power, causing the alternator to

produce less. The better regulators will also accept battery temperature

sender input to prevent thermal runaway.

Unlike the rectifier, the alternators output amperage never goes

through the voltage regulator. The area of concern when changing

to a high output alternator is the amperage draw of the rotor

and consequent change in the field current amperage. The voltage

regulator is also sensitive to heat and should be mounted outside

the engine compartment, the length of the cable run and the current

determine the wire gauge required for the field current. Voltage

regulators do have a field amperage rating and because it has

direct contact with the rotor you should be concerned with the

amperage draw of the rotor in order to size the wiring accordingly.

If the amperage draw of the rotor is greater than the rating for

the voltage regulator the regulator will fail. Some alternators

have the brush mounts built into the body of the regulator, on

others they're separate and permit easy removal of the regulator.

A separate switch for the field wiring can be used to "shut

down" the alternator. The field current controls whether

the alternator is turned on and generating AC voltage. A dry cell

battery, appropriate for providing the field current, can also

be wired up to the switch as a backup to insure that the alternator

will charge a dead house battery bank if you can get the engine

started. (This is problematic if your engine has common-rail injectors

or "glow-plugs" which require a lot of current).

| Ample Power’s Next Step Regulator 12

or 24vdc ($299) |

|

3-step voltage regulators that emulate the Amp-hour Law are few

and unfortunately expensive. Ample has a good reputation for reliability;

the Next Step 2 w/ battery temperature sensor is both 12/24v capable

($299), and the V3 (12v -$449, 24v $499) has better field current

protection. Balmar have only fair reliability with several SSCA

members reporting replacing multiple units or "losing programmed

settings after a few days", wire size may play a role in

programming loss (?), and the mounting location may play a roll

in failures (heat sensitive). Ample and Balmar both accept battery

temperature sensor and alternator temperature sensor input to

control field voltage. The best 3-step alternator regulators are

ones which allow you to set the absorption voltage, the float

voltage, and the time-to-float independently and accept a battery

temperature sensor to prevent thermal runaway.

Procedure for Adjusting Absorption Charging Voltage

During absorption charging the voltage remains constant and the

current gradually tapers off as internal resistance increases,

so the charger needs to put out a higher voltage. Voltages during

this stage are typically between 14.2 - 15.5 volts in a 12 volt

system, (28.2 - 31 volts in a 24vdc system) and being able to

make small 50 millivolt changes can dramatically change the charge

current supplied. Our goal during absorption charging is to vary

the charge voltage until the charge current matches the "missing"

amp hours from the battery. Like a fuel tank you use the battery

monitor to determine the desired amount of current at any given

moment; if you're down 90Ah then you want to feed the batteries

90A of charging current. Adjusting the absorption voltage to match

the missing amps will result in a closer approximation of the

Amp-hour curve. This can recover lost battery capacity in batteries

that have only been partially charged and degraded. Here is the

procedure to follow:

1. Pick a time when the number of Amp-hours missing is slightly

less than the maximum charge current capability of your charge

source.

[Note: We know that the battery charger should

be sized to deliver approximately 25% of the Amp-hour rating of

the bank to guarantee sufficient current density to the discharged

plates for uniform conversion of the sulphate formation to oxide

formation. Such "good" charging may make a life difference

from as little as one year to 10 years.]

2. Increase the charge voltage to as high as possible. Note the

charge current. If the current is say 40A and you have 38Amp-hours

missing then leave it there, it doesn't matter what the

voltage is.

[Note: Be sure to check that your shore charger

or alternator regulator can allow the user to set the upper voltage

range well above 14.4v, 14.6v is a minimum. Also check to see

just how easy it is to make such changes.]

3. Keep watching the charge current versus the number of missing

Amp-hours and if the charge current exceeds the number of missing

Amp-hours by say 10% or more then consider lowering the voltage

again to make the numbers match. If the decreasing charge acceptance

current "tracks" the missing Amp-hour number within

10% or so you are in luck.

[Note: On succeeding charge cycles the voltage

might have to be set slightly lower because the battery has already

recovered lost capacity due to a better acceptance charge. As

the battery heads towards full the charge current acceptance of

the battery decreases tending to not make you have to change the

charge voltage perhaps at all.]

Adjusting Float Charging

Once the battery is back to near 100% the charging system switches

to float charging. Float voltage is determined by the acid concentration

and temperature period; 13.7-13.9v is a good float value for 12v.

There is a simple formula describing the at-rest cell voltage

as a function of the specific gravity of the electrolyte. The

time to transition to float is when you are almost full and you

will note a complete lack of tracking:

- For example, the charge current is 5A and you are only missing

2Ah.

- You should note at this time that no significant

temperature rise has occurred in the battery.

If it has then on the next cycle go to float earlier. Once you

have attempted Amp-hour law charging and the battery has been

on float, say overnight for shorepower chargers, (or all day

for solar), put the charger back on at the same drive level

that you used to get maximum current from your charger.

Once you have attempted Amp-hour law charging and the battery

has been on float, say overnight for shorepower chargers, (or

all day for solar), put the charger back on at the same drive

level that you used to get maximum current from your charger.

If the capacity of the battery has been recovered then the charge

acceptance current will be near zero - about 100mA per 100 Amp-hour

rating of the battery or less. If you observe this then the internal

resistance of the battery is minimum and the capacity is likely

to be maximum.

- Manually zero out any accumulation in your battery monitor,

if it doesn't zero automatically.

- From here you begin your discharge cycle and the end reading

will be accurate.

You can repeatedly get away with bulk charging only to approximately

80% capacity, if you periodically (once a month min.) fully charge

the battery bank as described above, you'll increase its service

life by years.

Time of Recharging

The math involved solves this equation:

Ic = Im(e-t)

Where:

Ic = the charge current available

Im = the number of Amp-hours "missing" from the bank

T = charge time

One integrates Ic versus time to get the total accumulation of

Amp-hours for a time period. One quick way to visualize this is

that one can get about 63% of Im in the first hour and one can

get 63% of the value of the remaining value of Im (at the end

of the first calculation) in the next hour. This will give you

a very close approximation assuming that the battery is charge

accepting, knowing when the charger becomes voltage limited, thereby

not being able to put out rated current.

AC Battery Chargers

|

Iota DLS-90 (12v) and DLS-27-40 (24v) Battery

Chargers with an internal IQ4 Charger control that does 3-step

charging ($185 - $400 ) |

I suggested earlier that for AC battery chargers powered by a

generator one way to reduce the charge time was to split a series/parallel

battery bank into two 12 volt banks, which halves the amperage

required for each bank, and use two high amperage 3-step chargers.

Join your two independent banks with a battery selector switch;

wiring one charger to each bank. This way each charger will have

the best opportunity to deliver rated current.

Chargers for use with a Honda EU2000 Generator - The small Honda

generators are small, light, relatively quiet, and have a fuel

pump capable of drawing gasoline from a larger tank or Gerry can,

all of which makes it more acceptable to cruisers running them

in an anchorage. Using Iota DLS-75 chargers the absolute maximum

current draw is 18A at the low end of the AC input voltage range.

That is the approximate output of a Honda EU2000 generator. Each

charger is connected to a separate 20A AC power circuit. (You

use an external IQ4 controller with the Iota chargers to make

it into a 3-stage charger. The IQ4 controller adds about $30 to

the cost of the chargers.)

The charging voltages on the Iota can be changed, but not independently.

There is a single screw which lowers/raises voltages used for

all 3 steps. On the older Iota chargers, the screw is accessible

from the outside of the charger, and for the newer Iota chargers

one needs to open the charger to access the screw.

Rick (Young) is the person who helped me to understand how

to hook up my two Iota chargers. Here is how it is set up:

4 Trojan T-105's are wired up in series/parallel arrangement

to give 2 banks of 12vdc. I have a 5kw diesel genset that can

power two 120vac 30A circuits . I have each Iota DLS 90 hooked

up to a single bank (2 Trojan T-105s wired in series). During

charging, I isolate the battery banks and run both Iota chargers

at the same time, allowing each DLS-90 to independently charge

its own battery bank. When charging is complete, I then put both

banks in parallel and drain them as a single bank, enjoying the

benefits of a slower drain rate since I'm drawing from all four

T-105s at the same time.

The system has worked flawlessly for us. The batteries, surprisingly,

are behaving like new still, a year later.

Everything is working very well now, these are well-built

switching power supplies. They don't get very hot. Thank you all

for helping me to select the proper equipment at a price that

didn't break the bank. I am very satisfied with the setup.

I wired one Iota 90 into each of my 30amp circuits. This

allows me to run both chargers and turn on an item or two during

bulk charging on either 30amp circuit. More flexibility than having

them both on one circuit.

Iota stands behind their products as well. I bought a DLS

55 w/IQ4 from a member here and it quit a month later. Iota replaced

it with a brand new unit - no questions asked even though it was

bought second hand. Now there's a company that really stands behind

what they make! I wouldn't hesitate to recommend or buy again.

The whole idea is that both chargers work at the same time on

the separated banks. Keep in mind that even with the battery selector

switch in "both" the chargers can still be operated

at the same time with their outputs essentially in parallel, you

just have an overall reduced number of Amp-hours being delivered

compared to operating with the two chargers because their outputs

won't be balanced.

One other way to charge batteries with a generator is by using

it to drive a truck alternator. This was what Bob Gayle was investigating

in his white paper4. He had a small Chinese Chagfa S195 IDI diesel

engine mated to an ST 7.5 AC generator and he drove an L-N "triple

nickel" alternator off the front pulley for battery charging.

This works much better for DC battery charging than any arrangement

of AC battery chargers, as your existing 3-step regulator can

be switched between the propulsion engine's alternator or the

generator's alternator for operation.

Alternative Charging Sources – Solar, Wind and

Towed Water Generators

While engine driven alternators can provide your bulk charging

needs, few independent charge sources work better for absorption

and float charging than solar panels. Photovoltaic (PV) solar

provides it's charging over a long time period (about 4 hours/day

from 10am to 2 pm), but with limited current, so solar is an excellent

charge source for the higher voltage/lower current demands of

absorption and float charging, which also needs to be supplied

slowly over an extended charging period. If your daily current

draw can be topped off during the day by solar you'll not only

increase your quiet time at anchor, you'll improve your battery

life dramatically (remember the DoD chart). If you reduce your

draw periodically by doing some shore based sightseeing a solar

array can replace the current draw of a refrigeration system and

give your batteries a long trickle charge to 105% capacity to

improve their life, all without demanding attention, or annoying

your neighbors, while you're off enjoying yourself. The biggest

problem with this rosy picture is finding the area (and the money)

for the solar panels needed to generate the power.

Unless you have a large catamaran you may have difficulty finding

sufficient area on a boat to mount enough solar panels to meet

your absorption charging needs, but getting sufficient area to

provide the demands of DC refrigeration is easier. This may change

in the near future. The solar photovoltaic (PV) industry is undergoing

a change from silicon panels to thin film CIGS panels, which should

significantly reduce the cost/kW for generating power down to

$0.50/kW. Firms like Nanosolar have developed a PV "paint"

that is printed onto thin sheets of aluminum using large printing

presses. The cells are then placed in a sandwich of insulating

glass. All of Nanosolar's current production from their San Jose

plant is being shipped to Canada for utility sized installations.

Konarka is another firm making flexible CIGS panels using heavy

mylar insulation, all their current production is going to produce

"utility" sized panels. It will be awhile before we

see these panels trickle down first to the residential grid connected

and then the off-grid markets. Flexible CIGS panels have the potential

to be incorporated into awnings, which will go a long way toward

increasing the area that can be utilized on a boat for electrical

charging at anchor. So the future may be bright, but won't be

around to help us for awhile.

Pulse Width Modulation (PWM) Charge Controllers

were developed jointly by Sandia National Laboratory, Morningstar

and Digital Solar Technology5 to charge batteries using PV solar

arrays. To improve solar battery charging, they operate on a different

principle of pulsing the charge current. The charger is periodically

isolated from the battery and battery open circuit voltage is

measured. If open circuit voltage is above a preset limit, the

charger remains isolated (shunted); when open circuit voltage

decays below that limit the charger is reconnected for short periods

- pulsation. The open circuit voltage, charging current and the

pulse period duration are chosen so that when the battery is fully

charged, the time for the open circuit voltage to decay is the

same as the pulse duration. When the charger controls sense this

condition, the charger is automatically switched over to the finish

rate current, where short charging pulses are delivered periodically

to the battery to maintain it at full charge.

Wind Power - Despite the fact that wind generators

with a decent 15-20 kt wind can generate electricity for battery

charging, they have not been as widely accepted amongst cruisers

for several reasons:

- For them to work you need to anchor in a windy, more vulnerable

anchorage.

- The perceived threat of what might happen if a bird flew into

the fragile blades that are madly spinning over your head, and

the resultant flying shrapnel.

- The noise of the fan blades. An Air-X wind generator can generate

80dB of noise, compared to the 56dB of a Honda generator, (Remember

that decibels are a logarithmic scale, so every 3dB doubles

the noise output). It's no wonder then that George Buehler once

wrote he had to be physically restrained from throwing an oar

blade in a nearby wind generator.

|

There is nothing to mitigate the need to anchor in windy places

or a "perceived" threat of flying shrapnel - you have

to live with those. The noise you can improve by sanding all the

casting flash off the propeller, and reshaping the leading and

trailing edges to be smooth. If you look at the surface of the

blades with a magnifier you'll see tiny "craters" caused

by air bubbles in the mold process, each of which will tear air

and make noise. You can fill these micro-holes with wax or varnish

to reduce the noise level.

A German firm (Spreco LDA at https://www.silentwindgenerator.com)

started making blades for the Air-X wind generator based on wind

tunnel refinements to the propellers used in the Gossamer Albatross

solar airplane. They now offer a version of the Air-X generator

with all their aerodynamic improvements for 1,140 euros (about

$1,600 or roughly a $300 increase over the standard Air-X marine.

generator). One of the chief improvements touted is a reduction

in noise and improvement in efficiency in light winds.

Towed Water Generators are described by Francis

Kinney in "Skene's Elements of Yacht Design" (1973)

and by Steve and Linda Dashew in "The Circumnavigator's Handbook"

(1983). Intermezzo II his first Deerfoot design had a separate

through hull for a prop powered alternator. Some people today

are pushing the idea of hybrid (electrical) propulsion by touting

the idea of "regenerative sailing" using the propulsion

prop to generate electricity. Anyone considering this should note

that Dashew never used one on any of his subsequent designs. Anyone

attempting this will discover as I'm sure he did that in practice

it just doesn't work well.

Luckily for us a group of enthusiasts on the Yahoo Electric Boats

Group (https://groups.yahoo.com/group/electricboats/)

have investigated this extensively. One of the first facts they

discovered was that for a towed water generator to work the pitch

of the propeller has to be the exact opposite of a prop designed

for propulsion, (try reversing the propulsion prop around in mid-ocean

when the wind picks up). They also found that the output was far

less than they anticipated, because the water chooses the path

of least resistance and moves around the towed prop like a rock

in a river. Though everyone in this group approached this application

with enthusiasm and ingenuity they found that electric propulsion

is limited to day sailing on small boats with the batteries sized

to get you in and out of the marina, where you use abundant shorepower

to recharge them.

Given the choice between these alternative charging sources I’d

choose to invest in solar every time.

Electrical Installation -The appropriate wire

varies depending on the voltage and amperage output of the alternator

and the distance to the externally mounted rectifier and are shown

in the chart on the next page. Check the alternator output at

the battery at full charge with a clamp amp. You should be able

to trace all the way back from the alternator. The issues start

when the alternator is producing 125A, but the battery is only

receiving 10A, because the charge is leaking along the way through

a parallel path via other devices. Clamp the propeller shaft also

since this is often a source for electrical leakage and consequent

corrosion problems. Ensure that the output cables are adequately

supported and that nylocks (preferably) or lock washers are used

on the studs. Only used tinned copper wire for the cables.

When upgrading to a higher output alternator you should always

install a larger wire between the alternator and battery. Even

with a standard output alternator you will get better performance

and life out of your alternator if you upgrade the main battery

wiring. The original wire just isn't large enough for proper power

transfer. If you are using your alternator to its maximum output

or when you upgrade to a higher output alternator you must increase

the wires size. An alternators ability to send the power it is

making to the battery is directly related to the wire size and

quality of connection between the alternator and battery. A wire

that is too small when used on a high output alternator can cause

the alternator to overheat, burn up and fail.

Another area that receives little attention is the ground. You

must also improve the ground as well. A poor ground will hinder

the alternators ability to send power to the battery and can burn

an alternator up just as fast as an inadequate alternator to battery

wire. You should isolate the casings from the negative output

terminals, never ground through the engine block.

The engine head or block isn't designed to carry large amperage.

Grounding through the engine is the #1 cause of diode

failures, not to mention stray current corrosion out through the

prop shaft. Your ground may be fine when you first install

your alternator but over time corrosion and resistance builds

up in the ground connections. This is why it is best to run the

ground directly from the rear of the alternator to the battery.

Be careful to allow for flexure in the cables leading to the engine

and also provide chafe protection for all cables.

When installing a high output alternator to replace an existing

one you don't necessarily need to rip out your old wiring. You

can piggy back a second wire between the alternator and battery.

The main battery wire connected to the back of the alternator

has power to it at all times, even when the vehicle is shut off.

You connect this wire like normal then you run a second wire between

the alternator and battery. The power coming out of the alternator

will treat the two wires as one, power following the path of least

resistance.

Run the alternator cables directly to the batteries through a

250A fuse on the positive side of the battery. This allows you

to pull the fuse to isolate the alternator for service.

Physical Installation - Ensure lock washers

and Locktite or use Nylocks on all the bolts used. Pay attention

to the belt tension. Too tight and you will prematurely wear the

water pump bearings. Too loose and you get excessive belt wear

and heating on the alternator pulley which transmits to the alternator.

Use this test; when the engine is cool and place a rag on the

alternator fan and rotate the pulley so that the engine crank

rotates (yes, the pulley ratio mechanical advantage will enable

you to do this). If the belt slips the tension is too loose. Tighten

the pulley JUST so that it doesn't slip with this test and you

will be fine. Keep checking the tension over time.

Battery Selector Switch - Be judicious when

choosing a battery selector switch for use with starting motor

currents. Some diesel start motors have locked rotor currents

of 900-1800 Amps and most switches will not reliably carry that

load for years. Cole Hersee has good switches that have proven

to work over time even with loads above their ratings. Perko switches,

however, have failed (in my experience) even with motor loads

within their ratings. Other switches also may not fare well over

time.

Sulphation, Internal Resistance and Battery Aging

Expect very small numbers (< 0.01 Ohm) for a new fully-charged

battery. Expect a non-linear increase in Ri, as the battery discharges.

As noted, you'll want a chart of numerous Ri calculations, at

varying state-of-charge.

References

1 Hydrocap Corp. 975 N.W. 95 Street, Miami, FL 33150 phone:

305-696-2504.

2 “Lead Acid Traction Batteries” by Edward M. Marwell.

Eugene P. Finger, and Eugene Sands © Curtis Instruments 1981.

All rights reserved. Library of Congress Catalog card 81-65733;

ISBN: 0-939488-00-0

https://evbatterymonitoring.com/WebHelp/Battery_Book.htm

3 “E.E. Owner - How a gifted electrical engineer set up

his dream boat”, by Ben Ellison Nov 2007, Power & Motoryacht,

https://www.powerandmotoryacht.com/boat-electronics/electra/

4 "Operation of the Lundell Clawpole Alternator at High

Power Density and Efficiency"; by Bob Gayle; Three Cedars

Research and Development Bob Gayle's white paper on high output

alternator efficiency is only available by joining the Society

of Micro-Cogeneration R&D/Microcogen. info Forum (it's free).

Here is a link to the thread where the paper is: https://www.microcogen.info/index.php?topic=157.0

5 "Battery Testing For Photovoltaic Applications",

by Tom Hund @ Photovoltaic System Applications Department, Sandia

National Laboratories, Albuquerque, NM 87185-0753 https://photovoltaics.sandia.gov/docs/battery1.htm

6 "AirX Fails Power Curve Tests", by Paul Gipe, January

29, 2003 https://eduhosting.org/windpics/airx.html

*****

|