|

VITA a Multipurpose Dinghy

LOA - 9' 10"

Beam - 4' 10"

Sail Area Main - 44 sf

Sail Area Jib - 21 sf

It is axiomatic that the jack of all trades does nothing well. There are exceptions, however. The Vita Dinghy is one. A list of desirable attributes might include the following: easy construction with minimal skills, low cost, permanently tight, strong and light weight suitable for car topping.

Vita is not a new design. The oldest drawings that I can find are dated January, 1965. Before Vita I designed and built a sharp bowed dinghy which I called "Diamond", 2.9m by 1.32m. That was my first Taped Seam boat, soon after I had read of the Mirror Dinghy In the magazine Yachts and Yachting of 8 February 1963. I was not happy with its stability characteristics. Lightweight sharp ended boats have a tendency to capsize if the crew weight is concentrated in the sharp end. So, I designed a pram using the same four by ten foot plywood panels. The length and beam were each increased by four inches. It makes a much roomier boat and I would expect it to be a faster sailer with the same rig.

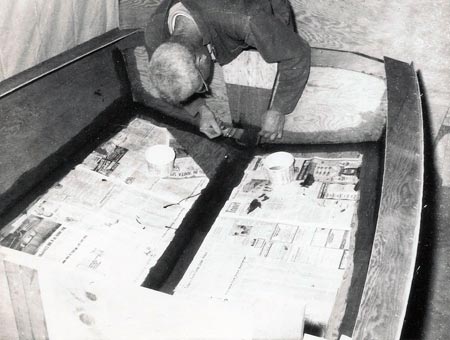

click image above to enlarge

Putting a divided rig on such a small boat is a moot point. It is good for teaching the young, or not so young, to sail the type that they may go to later. It may be rigged sloop or cat. so that the beginner may learn one sail at a time. The mast is made of stock aluminum tube, called construction pipe, simpler to use and less expensive than Sitka spruce. It is easily jointed with a wooden plug. There are two shrouds and a forestay, but minimum hardware. There are no rigging screws, adjustment is by lanyards and rings. The main has a sleeved luff, which is simple and clean, but some have chosen track and slides. A very simple, one sail, "No-Halyard" rig is an option.

I was particularly taken with the taped seam method and its possibilities for simplifying small boat construction. I first made a cardboard model which determined the shapes which I made full size on the bench. I used only a single former to hold the side and bottom panels in position. To get the intended curvature in the sides, which is a circular arc, I used temporary plywood formers inside, wired to the side planks at the sheer. This overcame the tendency of the planks to straighten out at the ends. That, plus the wiring of the sides to the bottom, develops the boat shape exactly as designed. I found a tendency of the transoms to deviate from position due to the side panel tension. I overcame this problem on this and later designs with tabs on the transom plywood which engaged slots in the side panels. There are no frames. Integral seats and partial bulkheads in the ends provide torsional stiffness as well as flotation.

The fillets at the seams are microballoons and resin. The seams are taped with fiberglass tape and the outside sheathed with fiberglass cloth and resin. It is essential that the outside sheathing goes on before the sheer stringers and the skeg to maintain continuity of the sheathing. The resin was polyester, but I have since switched to epoxy.

A fairly heavy, external, laminated sheer stringer goes on after the sheathing. It is laminated to shape from three layers of half inch mahogany. Since the parts do not require shaping in place, it goes on easily, without the usual frantic struggle to clamp and bond at the same time. Small temporary screws are used to hold it in place while bonding but there are no permanent fastenings except screws at the ends tieing it to the quarter and bow knees. The appearance and performance of the boat have exceeded expectations. The weight and size make it readily cartoppable. It has not been advertised, but scattered mentions in print have resulted in a number of plan orders, so there should be a few boats in service here and there in North America.

Joe Dobler at Havasu

It was not intended as a camping cruiser, but I found that with the board and rudder laid alongside the CB case, plus air mattresses, it made comfortable bunks for two, much better than sleeping on the beach. With a suitable boom tent it could be a snug retreat. If I planned serious camp cruising I might make plywood floorboards, which could be supported at seat level to make a sleeping platform.

Joseph C. Dobler 6-94

Construction

Constructlon is by the Taped Seam method. It is the simplest and easiest ever made to order for the person with no boatbulldlng experience.

The process briefly: You shape the plywood panels per the plans. Temporarily wire the parts together (no assembly jig required). Smooth off and fiberglass the outside. Attach trlm and paint. The result- a strong, light boat with an uncluttered lnterlor, that does not look like a first attempt. Even a rank beginner can do a professional looking job- all the difficult fltting and bevellng ls eliminated.

The result 1s a genuine all-purpose boat. It ls an ldeal sail trainer. Rig it first as a catboat, w1th malnsall only. Then, when you get the hang of sailing, change to the sloop rig for jib and mainsall experience. The performance is excellent. The wide beam and full bow give lots of stability and room. It is a good slnglehander, but not overburdened with four adults. The boat rows well, and though no speedboat, has good performance with a small outboard motor. It is fine for fishing.

All rlgglng ls slmple but effective, nothing complicated or expensive. The mast 1s made of stock aluminum alloy tubing. It is jointed so as to stow inside the boat. The shrouds have dacron lanyards for adjustment. The forestay and shrouds attach to the mast wlth quick disconnects. The loose footed malnsail ls made with a "sock", which slips over the mast. It is a simple, trouble-free rlg giving the sail a good aerodynamic shape. The sail may be quickly furled by tlelng it up to the mast with the outhaul.

The weight ls only about 100 pounds. The boat is easily car-topped, no fancy loader requlred.

The "V1ta" Dinghy is a one design class sailboat. Sail numbers are lssued to all authorized boats.

Origins:

The year was 1965. Bruce Embody, then living in Cocoa Beach, needed a small boat that he could sail around the canals and waterways. His wife, Phyllis, needed a stable, easily rowed boat for fishing. To meet those requirements I designed VITA, a sloop rigged V bottomed pram, 9'-10" x 5'-O". The construction is by the Taped Seam method, using all 1/4" fir plywood. Taped Seam. consruction, (lately called Stitch and Glue by some), was pretty new in 1965. It had many obvious advantages over previous methods for plywood - no chine logs, no keel, no frames, no stromgback or building form, no lofting, no boatbuilding expertise required.

The approach to building is quite different. I made a cardboard model to a scale of 1-1/2" to the the foot,(1/8 size.) From the model I made patterns for the side and bottom panels and the transoms. These were drawn up 1/8th size with layout dimensions for easy transferral to the full size plywood panels. The plywood requirements are one piece about 15" x 3O", one 4' X 8' panel and two 4' X 10' panelS. The

10' panels are available in marine plywood. The exterior sheer stringers are laminated on a simple form from three pieces of 1/2" mahogany. All outside surfaces are sheathed with fiberglass cloth and epoxy. At first we used resorcinol glue for gluing and polyester resin for sheathing, but since epoxy became avaliable we use nothing else.

The sloop rig may seem a little fussy for a boat of this size. Actually, it is quite simple and quickly rigged. The mast is a piece of commercial aluminum tubing, jointed so as to stow in the boat. The shrouds are set up with lanyards. The mast has two positions, for use with or without the jib.

Plans available at Duckworks

*****

|