I have a calendar with a picture of the Herreshoff Haven 12 1/2 in it. I look at the picture more than I should.

Wondering why, it has occurred to me the curving lines of the Haven has the quality of a young boy to it. It is

cute as boys can be, with just enough flare of the hull to be a bit dangerous, as boys should be. It looks small,

as if you could hold it in your hand. And while it looks uncomplicated, the sail, the rig, the layout are all the

result of years spent carving lines.

I get the idea Captain Nat spent some time questioning the need for everything he put on the boat. How little

coaming does a boy need? How many lines to the sails does a boy really need? How deep a keel should it be

to feel like a ship, without being slow or overcanvassed?

Did he stop one day in the Herreshoff yard while one was being built, to wish he’d had one like this when he

was a boy? I hope he felt a certain glee when his son Sidney sailed it for the first time, because the Haven 12

1/2 certain has given great pleasure to boys ever since. Unfortunately for those of us who don’t have the skill

Captain Nat’s great craftsmen did, the Haven 12 1/2 is difficult to build. I certainly could not build one as it

was designed.

Over the years, others have attempted to simplify the building without losing the ecstasy of sailing a Haven. Several years ago, Philip Bolger created a plywood and epoxy version. It has one chine per side, creating two

panels on either side of the keel. Those who have built the Bolger Plywood 12 have said it performs eautifully.

It is not trailerable. The original dimensions of the Herreshoff Haven are 16 feet overall, 6 feet of beam at the

deck. This means any attempt to be faithful to the dimensions and weight make it too big for a trailer. The

plans are $100, the last time I heard from Mr. Bolger.

Joel White drew a popular version of the Haven, but he made it shoal draft with a centerboard. It performs

probably nearly as well as the original, but Mr. White had to change the turn of the molds to shallow them. It

is a successful on its own terms, as the Doughdish is, and other versions. But it isn’t the same slack bilges,

deep long keel and sureness in light air.

So I was thinking, how close could I come to the Haven, and still build it myself? Carvel is out, and I don’t

want to take the time for lapstrake. But a compromise might be possible. What about a three panel per side

plywood hull, screwed and painted in the joint with paint on the outside and glue on the inside? Could that

work—I hoped it would.

What the Haven seems to have is three qualities Herreshoff loved to build into all his ships. A deep keel,

plenty of sail area to move the deep ballasted keel, and depth in the water. The Haven sits in the water with its

slack bilges—somewhat like a dory—so the generous sail are is needed to move it along, and the deep ballasted

keel is there to squeeze it on with all points of wind. The original gaff main gives it power on a reach, while the

jib helps out to windward.

|

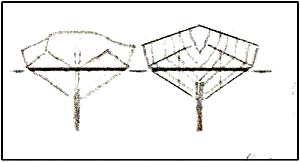

Such slack bilges are usually associated with rowboats. William Atkin

drew a 14 foot rowboat he called, ‘Pixie,’ which shows these lines:

You can see the deadrise, with the single chine above the waterline. |

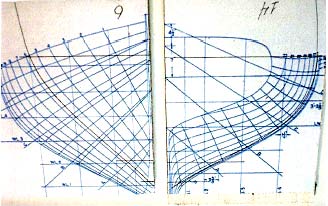

| Now these lines (in blue) are from a Haven build years ago. The

slack bilges are evident, with some softening at the turn of the bilge. |

|

It’s apparent Haven would row very well, and Herreshoff may have intended

it to be rowed in the tighter spaces of a harbor or yach club. Such a

shaping of the molds means the Haven will sit deeper in the water. It would

be tipsy were it not for the ballast. This also enables Herreshoff to put plenty

of room inside the cockpit while still having a slender shape in the water. So

we have the shape of a quiet rowboat with the power of a swift sailboat.

|

The underwater shape is deep. Here is an advertising image of the original HAVEN 12 1/2, with the tiller

through the stern. |

In 1974 Sidney Herreshoff, the oldest son of Captain Nat, wrote this about the original

design:

While managing the campaign for RESOLUTE during

the trials of 1914, Robert Emmons got my father to design

a small ballasted, sloop rigged boat that would be suitable

for teaching small boys how to sail and to become familiar

with the characteristics of the type of larger boat to which

they would later graduate. The first boat was ROBIN, at

the price of $420.

You can see from the drawing the sail area is generous, 140

square feet. In the Joel White version, he gave his 133 square feet

of sail. Skiffs at this overall dimensions usually have around 100

square feet, but with such ballast, the large main and jib are

needed. The marconi style of rig came into vogue at the 1920s

although races show it has no particular advantage. In fact, gaff rigs which have light spars are more versatile in

more points of sail than marconi rigs.

The Herreshoff designs of that era are well known for their beautifully curved sterns. What is interesting is

the similarity of the HAVEN stern and the stern of

Joshua Slocum’s SPRAY. Notice how parallel the underlines

of the stern transom are to the underwater lines

of the molds on the HAVEN, below in blue. With

SPRAY shown below that, you can see the same thing.

This must’ve simplified the lines by which the water

flowed under the aft sections. SPRAY had very little

underwater surface, so the vertical topsides probably

helped its directional steering. HAVEN had so much

more surface with its deep keel, it could have such flare

at the topsides.

The boat does sit deep in the water. Evidently the boys around Buzzard’s

Bay where Mr. Emmons lived sailed the first Havens pretty hard because

Captain Nat had to move the coaming in to create more deck space to prevent

swamping. Floatation was provided under the floorboards with a watertight

compartment before the mast. In later years an aft deck was put in—with the tiller coming over the deck—so that the space under the deck could

serve as stowage. Once the boys got away from the dock they probably

stuffed their lifejackets under there until the racing was over; I say this

purely on conjecture having been a boy once in ancient times. The boat does sit deep in the water. Evidently the boys around Buzzard’s

Bay where Mr. Emmons lived sailed the first Havens pretty hard because

Captain Nat had to move the coaming in to create more deck space to prevent

swamping. Floatation was provided under the floorboards with a watertight

compartment before the mast. In later years an aft deck was put in—with the tiller coming over the deck—so that the space under the deck could

serve as stowage. Once the boys got away from the dock they probably

stuffed their lifejackets under there until the racing was over; I say this

purely on conjecture having been a boy once in ancient times.

Finally, the rabbet is dead straight from the stem to the straight level

ballast. This probably makes the rabbet quite strong and easy to assemble.

It locates the weight of the ballast beneath the center of buoyancy,

keeping the trim level.

So we have a boat 16 feet overall with a sail area of 140 square feet, with 700 pounds of ballast. It has slack

bilges, a deep keel, a low exciting freeboard aft and plenty of cockpit space. While I can’t build this to the perfect

shape of Captain Nat’s dimensions, let’s see what we can do.

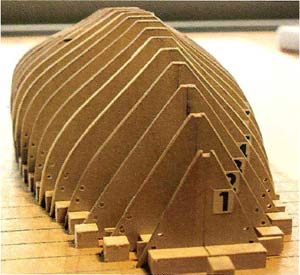

When Philip Bolger redesigned this classic for plywood in the SMALL BOAT

JOURNAL of 1987, he identified the two problems which an amateur will

have. First the forefoot is quite narrow even though the deck is wide, and second

the stern shape curves so much it can’t be duplicated.

|

The first mold is concave, the second is straight, but the third begins the convex

arc until the sixth mold is clearly convex. Plywood won’t do that—at least

not one sheet of plywood. And if you look at the lines for the transom on page

one, you’ll see that one, two, or three panels of plywood still would not get the

shape very close. |

So Mr. Bolger put a single chine in, above the waterline all the way,

and sacrificed the turn of the molds for straight plywood sheets. He

had to lengthen the bow in order to keep the forward section narrow.

And therefore he made the transom narrow, also. He angled the stem

and stern to get some of the beautiful shape back. All of this depends

on stitch and glue. The design does work, and the boat performs

quite well, from the reports of those who have built her. So Mr. Bolger put a single chine in, above the waterline all the way,

and sacrificed the turn of the molds for straight plywood sheets. He

had to lengthen the bow in order to keep the forward section narrow.

And therefore he made the transom narrow, also. He angled the stem

and stern to get some of the beautiful shape back. All of this depends

on stitch and glue. The design does work, and the boat performs

quite well, from the reports of those who have built her.

The one great issue with builders is the keel. It needs to be made

out of plywood so that the bolts are not too long. It also saves the trouble of solid wood warping with time.

However, as Mr. Bolger pointed out in the SBJ article, this removes about 100 pounds of ballast, which compromises

the performance. The plywood keel can be filled.

So this is one solution to building HAVEN out of plywood. As I said earlier, it is not trailerable which

means I can’t have this boat. So I’ve thought about making it trailerable. This means a lighter boat and less

depth in the keel. The Joel White redesign certainly shallows the keel, replacing it with a centerboard, but even

this boat is not much lighter. Can anything be done? Well, let’s see.

The keel will have to be made of two sides of plywood joined by a 1”x6” pine board. Fortunately the forefoot

keel is straight. We can make two compartments in the keel, or one. With two the lower one can be free flooding,

filled when sailing and emptied when trailering. It will be like the diagram here on

the right. The upper chamber can be empty or filled with solid wood, cut to fit tight.

This will prevent swelling and warpage. That’s what I’d do. Or we can make one chamber,

all free flooding for as much ballast as the water will provide. The daggerboard is

weighted with lead, and you can give it plenty or a little. The minumun would be measured

around 3”x5”, although I have not drawn that in. This arrangement keeps the

weight low while the boat is still light enough at the dock to get it on your trailer. The keel will have to be made of two sides of plywood joined by a 1”x6” pine board. Fortunately the forefoot

keel is straight. We can make two compartments in the keel, or one. With two the lower one can be free flooding,

filled when sailing and emptied when trailering. It will be like the diagram here on

the right. The upper chamber can be empty or filled with solid wood, cut to fit tight.

This will prevent swelling and warpage. That’s what I’d do. Or we can make one chamber,

all free flooding for as much ballast as the water will provide. The daggerboard is

weighted with lead, and you can give it plenty or a little. The minumun would be measured

around 3”x5”, although I have not drawn that in. This arrangement keeps the

weight low while the boat is still light enough at the dock to get it on your trailer.

And yet, more ballast would probably be needed. First, the daggerboard is weighted. Then the space under

the floorboards is available for additional ballast. I would use sacks of sand. Whatever is used needs to be easily

put in and removed.

The board at

the bottom of the

keel is a dagger

board. The shape is

there to enable it to be

lifted easily. It comes completely

up and out when the boat is trailered at the dock.

I’ve given you options here with ballast. Lake sailing

doesn’t need all of the ballast that open water sailing

does, since lakes usually don’t have currents. More

weight does not make for a slow boat or a bad light air boat. Usually it helps.

Hopefully that will get HAVEN on and off a trailer without incident. Now for the shape of the hull. While

plywood certainly can’t get the shape steamed planks get, it can be strong. While steaming a plank does weaken

it somewhat, the laminated layers of the plywood keep the shape of the boat when it’s out of the water. What

we’ll do is divide the hull into three strakes. One will be quite similar to the Bolger version, but the upper two

strakes will have a slender turn to them to create a stern transom which looks better than a simple rectangle.

The bottom strake or ‘garboard’ will be straight until the fifth and sixth molds shown here. The arch can only

be slight as the plywood is being bent around the molds to the stern. This arch just below the

lower chine is really only to bring it into the strake above it and to give the

transom a better shape. Now the strake above it, strake 2, has some

arch but not very much. I would say it’s about 1/2” in a

strake about 10” wide. How much strake 2 will

take is really a building issue. It can be

altered since it’s above the waterline, anyway.

This can be stitch and glue, or a traditional

batten let into the molds. That’s what I’d do.

As to  whether to put epoxy and fiberglass on the

outside, I’m not sure. You decide.

I have been thinking about Captain

Nat’s thinking process and how quickly

he carved models. It has been said he

would carve a perfect model in just a

few strokes, I would say that might be a

minute or two. It seems rather quick to

me. Obviously he did this since he was

a boy, and knew exactly how the wood turned and peeled. Surely the wood was the best wood

available, the same he used on his yacht interiors. Still, that’s pretty amazing to me. whether to put epoxy and fiberglass on the

outside, I’m not sure. You decide.

I have been thinking about Captain

Nat’s thinking process and how quickly

he carved models. It has been said he

would carve a perfect model in just a

few strokes, I would say that might be a

minute or two. It seems rather quick to

me. Obviously he did this since he was

a boy, and knew exactly how the wood turned and peeled. Surely the wood was the best wood

available, the same he used on his yacht interiors. Still, that’s pretty amazing to me.

When I look at the HAVEN lines I see three ideas, not one. First the narrow entrance, much like a canoe.

Then the turn of the bilge is always above the waterline, like a dory skiff with two chines above the waterline.

This is amidships. And the third idea is the transom

is just above the waterline, wide and flat like a skiff.

This is what Captain Nat said in a letter dated

1932, published years ago in the Herreshoff

newsletter:

‘My father always advocated boats of good

displacement. His own boats were of the heavily

ballasted keel type. My idea (in 1870) was to shape

the hull so the ballast would be lower, have the bilges

practically out of water so as to get easy lines when

the vessel is upright, and great beam that would give

stability when heeled in a breeze.’

I have on my desk the lines for H-28, twice the

length of HAVEN. All the elements of HAVEN,

mentioned in the letter are there. While the old

Captain made changes as the years went by, the elements he mentions are always there no matter how large the

craft. By the way, Captain Nat invented catamarans, in 1875.

And yet maybe we can simplify it even more, to bring it along the lines of a skiff with a keel. The first few

feet have to be fairly upright before the flare begins. To do this with plywood the stem has to be wider at the

waterline than at the sheer, with the Herreshoff overhang. Otherwise the flare would come too far forward, creating

slapping in the water. What we want is a gentle slipping of the water along the upright sides at the bow.

So I’ve draw the stem in a V-shape top to bottom. It is made in three layers to keep the water from blunting

the boat. Each of the three sections is beveled, although I don’t show that in the diagram below. The idea is to

move the water to be alongside the sides of the boat by pushing the water away from the bow. Each of the three

sections will be glued so the water can’t pound any nail or screw head.

The bottom panel is flat for about 2/3 of the waterline, until the stern begins to lift. The bottom panel’s sides

are fairly straight to accommodate the flare amidships and the stiffness of the chines. Then where I have drawn

a transverse line, the deadrise begins. The rise of the rabbet back up to the waterline has to be

gradual to accommodate this deadrise. I would make the bottom panel

out of one sheet of plywood, and then cut a split from the stern

toward the bow nearly to the transverse line. The cut will have to be

shaped to accommodate the upward turn of the panel as the

deadrise increases. The only criterion for how much the

deadrise increases is the chines at the transom have to be out

of the water.

| As you can see below, the keel is solid wood for rowing, free flooding for

sailing. I have not shown a daggerboard, as the bottom plywood is being

bent enough as it is. I wouldn’t ask it to take any more strain than this.

It’d be like asking a teenager to think on a weekend.

Since this is just a proposition, I think I’d build this shape without

any keel or board to see how it rows first. If the side panels do their

job, then I’d think about making making a sail. |

|

***** |