The idea

In mid-March 2006, I came up with the idea for my

new project, but at first it was only going to be

a model boat, not a full size one! It was to be based

loosely on the lines of a Lesro Javelin (Photo 1),

a model that has been around for many years and still

looks good. I was going to do my own version of it,

using one side-on photo that I scanned from an advert

and the length and beam measurement from the specifications.

It was going to be 38-1/2 by 11 inches with all other

dimensions worked out roughly from the photo.

|

Photo 1 |

I didn't know draught or hull shape below the water

and I was just starting to work on this area when

my friend suggested doing one to sit in! He offered

temporary use of a Honda 8 HP generator engine if

I wanted to build a full size one (Photo 2). After

a bit of computer magic on Photoshop, I ended up with

a photo of my head on the model at the scale I would

have to make it for me to fit inside, this resulted

in a 9ft boat roughly 32 inch beam. It looked good

(Photo 3).

| Photo 2 |

|

|

Photo 3 |

The main problem with my idea appeared when I managed

to track down a different photo of the Lesro Javelin,

stuck my head on it and it looked a bit too narrow

beam for where the centre of gravity was going to

be with me and the engine in it (Photo 4). My friend

appeared at this time and said: "I thought you

were doing it for two people,anyway" This is

where the boat started to diverge from the Javelin.

| Photo 4 |

|

After some measuring and mock ups with bits of ply

to simulate widths required for seating, I worked

out that I could fit two people and keep the deck/cockpit

side proportions if I made it 46 inches wide. I was

still keeping to the 9 foot length as I had a mock-up

photo of it already. I priced 10 ft sheets and decided

to cut £200 off my boat! I changed the length

to 7 foot four to get the sides from an 8 ft sheet

of ply. This adjustment required another Photoshop

job, shortening the length, but keeping the height

resulted in something that looked possible at reasonable

cost (Photo 5).

|

Photo 5 |

The plan

The plan started life on Photoshop (again). Using

the side photo, cropped to length of the boat, I resized

the image to make a 22 inch (1/4 scale) photo which

I printed on three sheets and taped together. I still

didn't know any of the 'underwater' measurements,

so I took my first try at weight estimation to see

what sort of volume I would need below the waterline

and came up with 8 inch deep 'V', which was marked

onto the photo and the missing curve added to meet

the bow. I traced the photo and started adding details

until I had enough information to work out bulkheads

etc.

At this stage I joined 6 bits of card and started

on my full-size drawing, using the same type of slotted

together construction as my micro

yacht used. I decided to use 3 laminations

of 3/4 ply for the backbone (I don't know if that's

correct term!) with a mixture of 3/4 and 1/2 ply bulkheads.

My steering was to be based on a gearbox from a dead

angle grinder, so suitable mounting was designed in

by using two ply braces spaced the width of the gearbox

apart and extending forwards to form the centre piece

between the dummy vents, which were going to be used

for ventilation but ended up mainly for looks. I may

try lights in them. I think the vents look better

than the flat panel that the Javelin has. The braces,

bulkheads and backbone are all slotted to key into

each other, making it hard to go out of alignment.

With most of my plan decided and drawn on the giant

carboard, I started to cut bits of ply. I must say

at this point, that the planning stage keeps going

until the boat is finished; particularly the order

of building. It is easy to get carried away and make

things difficult for yourself, like gluing on the

bulkheads before you have drilled the holes for the

steering and throttle, still possible, but not as

easy or neat as it could have been. Yes, I did that!

There were a few small things that could have went

pear shaped, I was routing a part and the cutter bearing

collapsed, allowing the cutter to decide it's own

path through my nearly finished bit of wood, luckily

it is an 'out of sight' piece, so I left it as a 'feature'!

Another close call came when I was cutting out the

transom, the ply I was using was actually swapped

for a model plane airframe. The friend I got the wood

from had drawn parts for his own version of the yacht

I built, but gave up. The problem happened when I

started following his line with the jigsaw! I realised

within 1/4 inch so it was not a disaster.

The dry build

Starting with the backbone centre lamination, I

then cut my master bulkhead which would be used as

a template to router flush all the bulkheads of the

same lower section. There are 5 which are the same

but have the tops trimmed after routing. Then the

template is trimmed to fit in its final position.

I made the other bulkheads with each edge angled to

fit skin curve at that point, to cut down on sanding.

My angles were pretty close, but there was a LOT of

sanding later to get framework pieces ready for eventual

'skinning'. No glue was used at this stage and I was

able to dismantle the parts and put them in my 8x4

shed after I had finished for the day.

I made up more braces to hold the top edges of the

front bulkheads in place and side rails for the rear/midsection

along with the rear portion of the cabin/cockpit sides

which braced the cockpit and engine bay areas together.

I added doublers to the backbone and adjusted the

bulkhead slots to final size and was now able to pick

up the framework, still with no glue! (Photo 6 and

7) I added more bits and worked out cable runs for

steering and throttle etc.

Photo 6 |

Photo 7

|

Now was the time to think hard about the engine

arrangements! What I had originally planned with 8HP

Honda motor never happened due to my engineering friend

getting busy at work again! I had designed the transom

to take an outboard or an outdrive unit that would

fit over the transom and I even had a lot of the parts

(Subaru cam belt and pulley, chain and sprockets etc),

but no cash to buy the square section steel tube for

the 'leg'.

My neighbour sold me a longshaft Seagull outboard

(non runner) for £40 (Photo 8), which I was

going to use for testing until we eventually made

the outdrive. A night's work had it running and cleaned

up a bit. Repainting the tank finished the restoration.

Next morning, I fired it up to let him hear it. He

looked as if he wished he hadn't sold it!

| Photo 8 |

|

Still keeping my hopes up, I designed the mountings,

throttle and steering to take an inboard motor in

case it ever happens! The transom and engine mounting

plate are laminated ply 2 inches thick and are locked

together with the backbone and bulkheads (Photo 9).

It is very solid and that's before any glue goes near

it. The glue stage was approaching, there wasn't much

more I could do until I glued at least some of my

'kit' together. The trouble was I didn't have a big

enough shed to build it in. A 2.4 metre square gazebo

was fixed to the side of my shed, I added tarpaulin

sides and a portable CD player and I was ready to

glue!

|

Photo 9 |

The Build

I started gluing the bulkheads on one at a time,

using the other bulkheads and braces to hold it until

glue set, then I removed braces etc. and glued in

the next bulkhead and braced it up again. It seems

like a long process, but it ensures that everything

stays where it is supposed to. When all the bulkheads

were fitted, I glued in the braces, added gussets

and ended up with a rigid framework to fit my stringers

(chines?) to. These were steamed using a wallpaper

stripper and a chamber made from 3x3 and a large plank

laid over the top. I clamped them to the boat with

no glue and let them set in that shape. This was not

as effective as I thought it would be, and instead

of a 23 inch curve it sprang back to about 3 inch

curve. I cut notches in the bulkheads to accept the

stringers then glued them in place, added gussets

and could now see some very nice lines appearing on

my frame (Photos 10 and 11).

| Photo 10 |

|

|

Photo 11 |

I fitted the deck first, then bottom skins (Photo

12) to give me access through the sides for varnishing

and to the underside of the steering area (Photo 13).

I left the sides off until the last moment, varnishing

all the bits that would be hard to get to later. I

fitted the steering and throttle to make sure it all

worked, then removed it and glued the sides on - sounds

easy.

| Photo 12 |

|

|

Photo 13 |

Glueing the sides on required 2 very late nights

to give me a chance to get the glue onto the frame

and the side clamped on before the glue dried. Mid-day

in summer gives about 4 minutes to get this done.

Clamping was the hardest part as I was running out

of things to clamp to and I did not want to use any

screws (Photo 14 and 15). I eventually managed it

and after trimming off the excess, I could see a solid

version of my idea.

Photo 14 |

Photo 15

|

I was worried about water getting on my raw wood,

and the boat had it's own brand new tarpaulin, which

was lucky, as a nights worth of Scottish rain had

broken the peak of the gazebo which filled up like

a pond and was hovering over my boat with about 20

gallons of water straining the fabric and dripping

everywhere. I managed to soak myself but the boat

stayed dry. The poly-shelter was repaired and re-taped

to keep the midgies and moths away from my varnish

and I spent a couple of weeks varnishing!

Varnishing and Painting

This deserves a section to itself as it is a critical

and major part of the build, requiring quite a lot

of time to be spent inside it, upside down with my

legs resting on the back of the seat, while trying

not to sweat on my new varnish! All parts, inside

and out, have at least 4 coats of varnish (Photo 16

and 17). I know a lot of people go for more, but I

was on a limited budget!. I had decided to see how

it looked with just varnish before venturing onto

painting. I had drawn an artists impression of it

(Photo 18), scanned it into the PC and printed off

a bunch to let me colour in a few different schemes,

so I knew roughly what paint scheme I was going to

do if the varnishing didn't look that good.

| Photo 16 |

|

|

Photo 17 |

| Photo 18 |

|

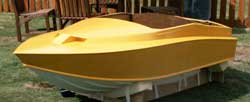

Due to using different woods, glue lines etc, I didn't

like the varnished only look and decided to paint

it yellow using 2 layers undercoat and 5 enamel topcoat

(Photo 19). I was going to do just three topcoats,

but after finishing my first tin of yellow, halfway

through the third coat, I opened my 2nd tin and started

rolling it on, then noticed it was a different shade

of yellow! I had not checked the batch number. I had

to finish that coat and do another 2 coats before

the original shade was hidden. I will check batch

numbers next time! The bottom of the hull got 5 layers

varnish, 2 undercoat and 3 black gloss enamel (Photo

20).

|

Photo 19 |

| Photo 20 |

|

Fittings

Steering is by ropes running around home made ply

pulleys which have mitre saw guides as pulley shafts

and tubing from a baby bouncer as bearings, onto a

drum attached to the angle grinder gearbox (Photo

21), with a laminated ply steering wheel (Photo 22)

which uses a Nescafe coffee jar lid for it's centre

and another to cover the steering bearing (I like

re-cycling)(Photo 23).

|

Photo 21 |

| Photo 22 |

|

|

Photo 23 |

The tiller arm of the outboard points down into the

area that was going to be the engine bay and has the

steering ropes attatched to the end of it. This led

to the hatch being different to the one in my artists

impression. Throttle is from bicycle gear lever and

cables (Photo 24).

| Photo 24 |

|

I forgot to mention that my daughter's outgrown wooden

bed was used extensively during the build. The head

and footboards supplied large pieces of wood for the

transom, seat back reinforcement, and numerous other

bits. The lower slats from the bed were very useful

for clamping the outer skins to my framework..

There are a total of 198 wooden parts in my boat.

Some parts could have been made in one piece but would

have required more full sheets of ply, which I didn't

have. The windscreen was made from a piece of perspex

that my friend offered me. It is as large as I could

manage from the oddly-shaped bit. The chrome bits

came from a light fitting reflector. Rubber edging

was in deep storage for twenty years before finding

a home! Upholstery was made from a cowskin that someone

gave me years and years ago. All hand stitched by

myself, it was a pleasant break from sanding and varnishing

and has ended up being quite comfy as well!(Photo

25)

|

Photo 25 |

Launching

This is the bit that keeps you going to the end

of the project and it had arrived (Photo 26) about

four months after starting to cut my parts. The boat

was placed on the construction stand that I made from

6x2 timbers and 3/4 ply end plates. The boat and stand

were lifted onto a motorcycle trailer and ratchet

strapped down. During transportation the stand collapsed

a bit and I thought my creation was going to end up

sliding down the road at 50mph! It didn't.

| Photo 26 |

|

We got to Loch Lomond and registered for a year's

use of the Loch for £5! The boat was lifted

into the water, Seagull outboard attatched and I got

in for the maiden voyage. I managed two pulls on the

starter cord before I was blown back towards the beach,

a good push by a friend and I was able to give it

another try and it started! I wasn't exactly skimming

over the waves so I tried full throttle but discovered

that it was at full throttle already. Any thoughts

of calling it a speedboat would have to go on hold

for a while!

I did have fun, but would have liked a bit more

speed.It felt stable in the water and coped with quite

large waves, well, they seemed large from where I

was sitting. I cruised about for about 5 minutes by

myself then went in to pick up my friend. Having the

extra weight aboard did not seem to affect the speed

noticeably, so we ventured out a bit further into

even bigger waves, glad that the dummy vents on the

front were still watertight! The maiden voyage went

without any problems apart from lack of speed(Photo

27).

|

Photo 27 |

I must say that I enjoyed the entire project (Photos

28 and 29), with varnishing maybe a bit less enjoyable

than sawing and gluing. It has ended up a bit heavier

than my estimate but I reckon it's tough enough to

go through a Jetski! Not easy with a Seagull engine!

That was about to change!!!!

| Photo 28 |

|

|

Photo 29 |

Someone's Trash

A strange thing happened when I was going to visit

my wife in hospital after a scheduled operation. I

got a phone call from a friend who was dumping rubbish

at the local waste depot. He wanted to know if I wanted

an outboard engine that was being dumped. "What

size", I said, "9.9" came the reply.

I said that I would take it. He said: "do you

want another one that's here, it says 9.9 as well?"

I told him to guard them till I got back from the

hospital and picked them up.

Two Evinrude 9.9 HP, one short shaft (1986) and siezed

solid and the other a longshaft (1983), which turned

over, but had been ripped forcibly from it's mount,putting

a 'Z' bend in the gearchange shaft and wrecking the

casing in a few places. Both were covered, and as

I later found out, filled with what I call seacrust.

I could not see the thermostat when I took the cylinger

head off.

A month or so of cleaning, swapping and painting

parts has brought the motor to the stage it is at

now, about a 50/50 mix of the two motors and requiring

2 seals, a circlip and one mounting bolt. I have just

ordered these parts, but due to having parts of 2

engines, I have to try and explain why I need 3 parts

for an '83 motor and one part for an '86 motor. It

did need rubber mounts but I managed a very good refurbishment

with a scrap of denim and some superglue! Don't laugh,

I saved about £50 by repairing them.

I also need 2 sheared bolts removed, which my engineering

friend assured me he would find time to do! I need

to wait until it is all back together before I find

out if it is going to run. One set of electrics was

corroded very badly. Luckily it was from the siezed

motor. The motor cover was going to be sprayed yellow,

but I decided to cover it with heatshrink covering

for model aircraft, using a surface primer to etch

the plastic before carefully ironing it on. I must

admit that I have built and covered about 90 planes

with this type of stuff, so I am quite good at it.

It is very easy to end up with a lot of air bubbles

or creases.

I then cut the Evinrude lettering from black Fablon.

I think it looks pretty good compared to how it looked

when I got it (them). The photos don't really show

how bad they were. Before (Photo 30 and 31) and after

(Photos 32 and 33).

Photo 30 |

Photo 31

|

Photo 32 |

Photo 33

|

I mounted the empty casing on the boat for the photo

(Photo 34) but I will have to wait for my spares before

I can go further. I still have to make up a bracket

for my steering to attach to and fit my throttle cable

to the carb, but I will probably leave these jobs

until I hear it running. Hopefully it will run and

my 'boat' will become a Speedboat. I haven't seen

many boats of this size, so I don't know what to expect

from 9.9HP. I was a bit worried about 'copying' the

Javelin, but I think there are enough differences

to call it my own design ,it is shorter, wider, has

nice vents, different windscreen, is outboard powered

and most of all, it's full size and a two seater!

Hope you like it. Andy. PS. You can never have too

many clamps!

| Photo 34 |

|

|