| When I started building a Ducktrap Wherry last

winter I realized right away I did not have the proper

clampage to do the job. Like so many of you I have

a bunch of “C” clamps and lots and lots

of spring clamps, but except for very largest spring

clamps none are suitable for clamping laps. So, on

a fine brisk morning I decided to remedy the problem.

I studied what I could find on clamp making and determined

they are really not something that should take an

engineering degree to figure out. So I came up with

this simple but effective design that will no doubt

become the world standard lapstrake clamp. You can

build them for under 50 cents each – if you

build about 80 or so. Here is the design – free.

|

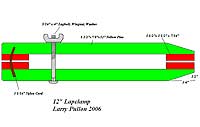

12" Lapclamp |

To build the clamps I bought two 2”x10”

yellow pine boards, 100, 5/16’x4” lagbolts,

100, 5/16” washers, and 100, 5/16” wing

nuts. I happened to have 50ft of ¼” nylon

cord on hand. Material cost was about $40 which made

my clamps cost about 50 cents each. Labor is always

free for home stuff!

|

I ripped nine

7/8”x 1 ½” wide boards out

of a 2x10 then ripped the remaining piece to

7/16”x 1 ½” wide. |

Setting up a clamp assembly line, I ripped nine 7/8”x

1 ½” wide boards out of a 2x10 then ripped

the remaining piece to 7/16”x 1 ½”

wide. There was a sliver of wood left… Next

I set the chop saw and proceeded to cut all but the

last two boards into one foot long blocks –

I think I got 170 blocks. Then I set the saw up to

cut 340 1 ½” x 1 ½” blocks

to serve as the clamp’s pads. With that done,

I next beveled one edge on each block – you

can skip this, it is just for visual effect –

but then you want to look good when you are boat building!

|

I next beveled

one edge on each block – you can skip

this, it is just for visual effect – but

then you want to look good when you are boat

building! |

Moving to the drill press I set up a jig to drill

holes in the blocks for the clamping bolt. It could

have been anything – but I drill the holes 3

½” from the end. Once holes were drilled

into all the one foot long blocks I set up a clamp

assembly line on a sawhorse table. I put a heavy drop

of Titebond II glue on each end of the blocks and

glued on a 1 ½”x 7/16” block on

each end. I could have held it together by tightening

the clamp – but I chose to use the nail gun

to hold everything in place until the glue dried.

Besides nail guns are cool!

|

Wham! The nail

shot out the side of the block right into the

tip of my left index finger! |

About the fifth or sixth block - wham! The nail

shot out the side of the block right into the tip

of my left index finger! Ouch! Razza, frazza, dip

wad, shifting sand!!! (cuss, cuss, cuss).

Once I stopped the bleeding I figured the odds of

that happening again were very remote and went back

to work. Holding the clamping block between my left

index finger and thumb, I moved quickly, firing two

1”x 16 gauge nails at a potent 95 psi. into

each block. That should hold the sucker until the

glue dries! Arr, arrr, arr!

|

I figured the

odds of that happening again were very remote

and went back to work. |

And three clamps later – blam! Another nail

shot out sideways – right into my left thumb!

Ewwwww! Awwwww! Son of a !@#$! (major cussing this

time!) There might have even been a tear running down

my cheek - but you don’t know that for sure

since you were not there!

Fortunately the inside of my thumbnail stopped the

nail from blasting completely through my thumb –

that would have been gross! While I was capturing

the “Kodak Moment” for your pleasure I

recalculated the odds that a nail would blow out the

side of a board again. I came up with 1:1 or 100%.

I was right - it happened 12 more times while I made

the rest of the clamps – I held the blocks differently

though, so no more nails fired into my poor fingers!

|

I installed

bolts, nuts, and washers, and then it was off

to the belt sander to remove any wood burs or

splinters and round the corners – just

to make them look nicer. |

After nailing all the clamp pads to hold them while

the glue set, I installed bolts, nuts, and washers,

and then it was off to the belt sander to remove any

wood burs or splinters and round the corners –

just to make them look nicer. Once the sanding was

done, I went back to the drill press to drill holes

for the cord. The cord is there to simply keep the

clamp halves aligned when not in use. They make it

so you can pick up a clamp and use it right away without

jiggling around with the halves.

|

And just like

that – in easy day I had made 85 nice

clamps that will serve me years to come. |

And just like that – in easy day I had made

85 nice clamps that will serve me years to come. They

would have cost a fortune from supply houses! I saved

so much $$ I could even afford to build a plywood

box on wheels to keep them out of the way!

|

I saved so

much $$ I could even afford to build a plywood

box on wheels to keep them out of the way! |

Articles by Larry Pullon

|