|

One-Sheet

Baby Canoe Part 2 |

| By Gaetan

Jette - Sherbrooke, Canada |

Part

1 - Part 2 - Part

3 - Part

4

Construction

Begins

I took many photos during the building

phase, but I did not write down a log. I'll try to

comment the building as best as I can remember. This

will be a detailed account, too detailed perhaps for

those who have already built a few boats. But since

this will be mostly a pictorial essay, it will be

easy for readers to skip what is old news for them

and concentrate on the more interesting details (I

hope). Now, I am a novice boatbuilder and I am not

a highly skilled or experienced woodworker either.

I do not claim this is the best way to build a boat,

it's just how I managed to do it.

Here is the lumber material list for

this project:

| Description |

Quantity |

Use |

| Plywood, 1/8 in. thick, 4 ft.

by 8 ft. |

1 |

Hull and paddle blades |

| 2 x 4 lumber, 8ft. long |

4 |

Backbone and center frame,

seat mold |

| 2 x 6, 12 ft. long |

1 |

Inwales, outwales |

| 1 x 4 plank, 8 ft. long, softwood |

2 |

Keel and other stuff |

| 1 x 4 plank, 8 ft. long, hardwood

* |

1 |

Paddle shaft cutting jig |

| 1 x 2 pine, 8ft. long |

1 |

Edge of center frame |

| Waferboard, 1/2 inch thick,

4 ft. by 8 ft. |

1 |

Support for keel assembly, plywood

marking; patterns for paddle blades, center frame |

* or any plank with sharp, square

edges

|

I used marine

grade plywood, but a cheaper luan ply might

do. The few luan samples at the local lumberyard

were not in good enough condition for the job.

The epoxy gallon I purchased was more expensive

than the plywood anyway. |

|

Lines are scribed

across the width of the sheet, six inches apart.

A drywall T-square proves handy for that. Then

all dots for one side of the boat are marked.

The arrows on the top and middle planks indicate

where are the bow and the top: these 2 planks

are not symmetrical. |

|

With the waferboard

used as a backing, nails are driven in the plywood.

I used an aluminum flat bar as a batten to trace

the patterns. |

|

A flexible plastic

ruler is used for tracing the sharpest bends.

|

|

The bottom plank

is traced right at the edge of the sheet. Nails

just outside the plywood, wrapped with electric

tape, allow to keep the curve fair as it moves

away from the edge. |

|

A "rough" cut

is made to split the sheet in two, but that

cut must be done as close to the line as possible,

due to a very tight spacing between planks.

The gap along the center of the sheet is under

a quarter inch wide. |

|

|

The

two halves are clamped together and the area

used for the breasthooks is cut off. |

|

Tracing the patterns

for 4 paddle half-blades (top) and 4 cover plates

(bottom) is made easier by cutting patterns

in the waferboard. |

|

|

Here

is the center frame. 1 x 2 pine is screwed along

the edge. The notch at the bottom is where the

keel will be fitted. The notch at the top is for

the off-center backbone. |

|

The parts for

the keel are dry fitted. You can see that all

the patterns were cut on one side of the waferboard

sheet, leaving the full length available for

the keel assembly. |

|

Because this

boat is built with a keel, I chose to mark and

pre-drill all the stitching holes before assembly.

|

|

A few machine

screws are placed in the stitching holes to

keep the 2 plywood layers clamped together.

Each part is rough cut with a hand saw and then

a coarse metal file is used to trim down to

the scribed lines. Not the fastest way to do

it, but I find it too difficult to control a

circular saw freehand. |

|

My Workmate proved

handy when dealing with smaller parts like the

paddle cover plates shown here. |

|

One sheet, one

boat. Some assembly required... |

|

Moving to boatyard

number 2. This project would never have happened

without my brother letting me use his utility

shed. This is where I spent most of my spare

time that summer. |

|

The keel is assembled

with loose tongue and grove joints. The tongues

are cut from the leftover plywood strips. The

grooves are cut on a table saw, just one saw

kerf wide. This was a bit tight however, so

some sanding was required for the tongues to

fit. The parts are screwed down on the waferboard;

a plastic film prevents the parts from gluing

to it. |

Unfortunately, my first epoxy batch

didn't cure. After one week, I had to disassemble,

scrape and clean everything and start all over. Fortunately,

this was also my last batch that didn't cure.

|

The keel curves

are scribed the same way as the plywood sheet

was. |

|

The sharpest

bends require more nails. You can see here the

tongues in the joints. |

|

The keel is cut

and the edges are routed with a quarter-inch

radius bit. |

|

The stems are

left longer in order to screw them to the backbone.

The wide stem with all those holes you see here

didn't prove to be such a good idea when dealing

with the epoxy fillets inside. |

|

The keel, center

frame and backbone are screwed together. The

2 x 4s at each end allow to the whole assembly

to rest on sawhorses, either right side up or

upside down. |

|

The frame has

to be braced in every possible direction. |

|

The top planks

are attached with screws to the center frame,

while the ends are attached with plastic ties

to the stems. |

Some stitch and glue designs use no frame

during construction, as described in Sam Devlin's

book "Devlin's Boat building" (at least for small

boats). Some designs use quite a few permanent frames,

like Phil Bolger's Cartopper. My design falls somewhere

in between, using a temporary center frame and a permanent

keel. I felt this would produce a straight hull with

little warp or twist, without having to build several

frames, and without some tricky alignment procedure.

As long as you glue the keel on a perfectly flat surface,

and that the 2x4s used for the backbone are straight,

the resulting hull should be straight enough.

|

The middle planks

are attached next. |

|

|

The

bottom planks are attached to the middle planks

first. The keel and bottom planks are then attached

with plastic ties in one loop: for each hole

in the planks there is a pair of holes in the

keel. |

|

A few screws

are necessary to force in place the ends of

the bottom and middle planks. Instead of pulling

the planks tight against the stems, the slim

plastic ties stretched under high tension. |

|

A few screws,

backed by small plywood squares, are also needed

on the bottom chine near the bow and stern.

These plywood squares were also cut from the

leftover plywood strips. |

One mistake I made was to assume that

the 4-inch planks I bought were 3/4-inch thick. It

seems that construction grade planks are 11/16-inch

thick nowadays. Well at least in the area where I

live. The center frame was built for a 3/4-inch thick

keel. As a result, the edge of the bottom planks could

not be pulled tight against the keel, especially near

the center frame. This made it harder for the edge

to follow the fair curve of the keel. A few match-size

splinters, slipped under the plastic tie loops (on

the inside) helped maintain proper alignment along

the keel.

|

Small splinters

are used to fair the keel side of the bottom

planks. This photo was out of focus so I sketched

over it. |

|

The first epoxy

fillets are done on the inside of the keel.

They have to stop short of the center frame.

I used the round corner of a plastic spreader

to shape the fillet. 3-inch fiberglass tape

spreads over the keel and both fillets. |

|

In order to achieve

fair curves along the chines, temporary outwales

were first screwed and clamped along the sheerline.

These temporary outwales will later become the

permanent inwales. |

|

Epoxy fillets

have now been done on both chines inside. I

used the lid of a cottage cheese plastic container

(about 4-1/2 inches wide) to spread the epoxy

for the chine fillets. |

|

Before starting

the epoxy work on the outside, I had first to

correct a mistake: I forgot to wrap the edge

of the frame with some plastic film. Luckily,

this is a small hull. Just a few screws to take

off and the problem was solved. |

Before doing the epoxy fillets on

the outside, the plastic ties are cut off first with

cutting pliers, then trimmed flush with a wood chisel.

|

|

The

fiberglass tape has been done on the outside.

The tape on the keel covers the epoxy fillets

on both sides of the keel, more or less. It

had to be cut in sections near each end: the

sharp curve would have caused too much wrinkles.

|

|

|

The

fiberglass fabric is laid on the boat and cut

roughly to size, in two halves. I decided to

cover only the bottom planks, with some overlap

on the bottom chine and along the keel. It might

have worked better to unfold the fiberglass

fabric a few days in advance. The wrinkles of

each fold proved difficult to cover with a minimal

amount of epoxy. |

|

Before the final

fairing along the stems, a notch is cut in the

stem where the outwale will rest. Lines are

scribed with a pencil, a sawcut is done on those

lines. Then a chisel, with the blade resting

flat on the top plank (at an angle so the chisel

handle is beyond the edge of the top plank)

is used to clean that notch. |

|

Time to fair

the sharp edges of fiberglass tape with thickened

epoxy. |

|

|

Coating

with clear epoxy. The fiberglass weave takes

several coats, which leads to the proverbial

epoxy drips. |

|

|

Looks

shiny form afar, but not truly smooth: still

more fairing to do. |

|

|

Still

more fairing: I even resorted to put the hull

on its side in the hope of reducing the dripping

problem. |

|

While epoxy was

curing, I had time to install the first few

inwale spacers. |

|

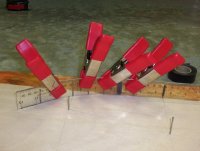

The paddles are

assembled for a dry fit check. |

|

The paddles are

glued using lightly thickened epoxy. The screws

are coated with beeswax to avoid sticking to

the epoxy while curing. Short lengths of 2x4s

in between the screws allow to apply pressure

with the improvised weight (the toolbox). |

|

The epoxy has

cured, but the tip of the blades didn't get

glued perfectly. |

|

Using a couple

of spring clamps and cleats, the paddle blade

tips are glued. |

|

Fairing the

paddles with thickened epoxy was next, one side

at a time. |

|

At long last,

the fairing on the outside is arriving at an

end. |

|

The hull is

removed from the backbone and frame; now the

inside has to be faired. |

|

Fiberglas tape

has typically one edge that is thicker than

the rest of the tape. Coated with epoxy, this

creates a bump that must be smoothed. I trimmed

that rough edge by using a small Dremel tool

with a router attachment, both outside and inside

(shown here). |

|

I chose to build

seat braces with a curve, in the hope it would

be more comfortable. Here that curve is scribed

on a form. |

OK, that's enough for this time. The

next part will show more work on the paddles and fitting

the inside of the boat.

On

to Part 3

REFERENCES

-

Samual Devlin: Devlin's Boat

Building, International Marine, 1996

-

Philip C. Bolger: Boats with

an Open Mind, International Marine, 1994

|