|

Building a Michalak Jon Jr. |

|

| By Tim Lehman - Steelton,

Pennsylvania - USA |

After building three kayaks and a canoe,

I decided that I “needed” something a

little larger. I wanted to be able to take my kids

out fishing and have room for some gear and maybe

even something to shade us from the sun.

I settled on a jon boat for its capacity and stability,

so I got on the ‘net and started looking around

at designs. I narrowed it down to three finalists,

all Jim Michalak designs: Campjon,

Jonsboat and Jon

Jr.

I gave it a lot of thought. Campjon

would be my first preference. It has an enclosed cabin

area for getting out of the sun and maybe even catching

a little siesta. It would also be good for keeping

the kids corralled and it’s certainly large

and stable enough. But I didn’t feel comfortable

taking on that large a project solo. I’m sure

I could have gotten someone to help me turn the hull

as needed, but then there was also launch and recovery

to think about. I figured better safe than sorry.

Jonsboat,

at roughly the same overall dimensions as Campjon

and 100 lbs lighter, started to look like a better

option. And I already had the plans in Jim’s

book. But my workspace is somewhat limited, so I turned

my attention to the Jon

Jr.

I ordered the plans from Duckworks along with some

other items that I planned to use on the project.

Then I waited patiently for their arrival. Fortunately,

it didn’t require a lot of patience. Chuck and

Sandra must do nothing all day but fill orders because

I received all of the hardware items in less than

a week after submitting the order. The plans came

direct from Jim a day or so later.

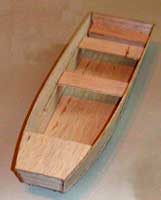

Once the plans arrived, I decided to make a model

first to get a better idea of how the boat would look

and to try out some ideas. I made copies of the panel

layouts and used them as templates for cutting the

parts from 1/16” balsa. Then I glued the parts

together in basically the same process as building

the full-sized boat.

|

I decided

to make a model first to get a better

idea of how the boat would look and to

try out some ideas.

(click

images to enlarge) |

|

I didn’t put the frames in. I didn’t

think that would have made a significant difference

in the way the model turned out. I was just interested

in getting to the basic shape so that I could visualize

it better and play with some ideas.

| I was just

interested in getting to the basic shape

so that I could visualize it better and

play with some ideas. |

|

|

I experimented with putting some sort of well/floatation

chamber in the stern, but I didn’t like the

look of it and was afraid that shifting the seats

forward to accommodate this feature would make the

boat hard to trim so that idea got scraped.

Next it was off to Home Depot for materials. Three

sheets of luan ply, a 2 X 6 X 12’ plank, two

tubes of PL Premium, a box of drywall screws and some

miscellaneous nuts and bolts.

The 2X6 was destined to be ripped into ¾”

X 1 ½” strips for chines, keels, gunwales

and frames. This technique yields nice vertical grained

stock at a good price. It was the clearest one that

I could find in the pile without spending all day

digging clear to the bottom, but it still had a few

knots in it, some of which came back to bite me later.

I wanted to use Chief Red Elk’s cloth-and-paint

method of covering the bottom, so the next stop was

Big Lots for a canvas drop cloth and a gallon porch

and deck paint. They were out of drop cloths so all

I got was a gallon of oil-based dark brown porch paint.

Wal-Mart had some suitable fabric in the dollar-a-yard

bin, so I picked up six yards. That was enough to

cover the bottom and both transoms with a little left

over. The bits that I trimmed off make good shop rags

and the extra half yard or so will get used for something

eventually.

Time to get busy…

I temporarily joined two sheets of ply with duct

tape, being very careful to keep the factory edges

aligned. I laid out the side panels and cut them out

leaving about 1/8” excess outside of the lines.

Then I removed the tape and joined the sections with

Payson fiberglass joints, again keeping the factory

edges aligned. After the joints cured, I clamped the

panels together and used the belt sander to sand down

to the lines.

|

Looking

Aft

|

|

I built the boat to plan with two exceptions. First,

I substituted 3/4" ply that I had on hand for

the transom and added a 1X6 doubler for the motor

support. Second, instead of a triple 1X for the outer

wale, I installed a single outer and a single inner

with spacers on the inside. I prefer this because

it gives me plenty of convenient places to tie "stuff"

off. The boat might not capsize, but things DO get

dropped over the side, so I try to keep everything

on some sort of leash.

| the bow storage

with cover off |

|

|

I wanted some means of closing off the bow compartment

for storage and emergency floatation, but I didn’t

want a deck hatch. I wanted to keep that area flat

so that one of the boys could sit there while we were

fishing. When we’re under way, they both sit

on one of the seats, but they need to be separated

when we fish.

|

back side

of hatch cover

|

|

I cleaned up the cutout from the opening in bulkhead

#2, cut a larger piece from some scrap and glued them

together. I used two lengths of 1X2 for the inner

latch and mounted them with long carriage bolts and

springs. The springs place just enough pressure on

the latch to force it back away from the frame when

the wing nut is loosened. A couple of stops on the

inside of the frame align the latches in a vertical

locking position. As the wing nuts are tightened,

the latch bars rotate until they contact the stops

and then they tighten down onto the frame. Likewise,

when loosened, the bars rotate into a horizontal position

and the hatch can be moved sideways to disengage first

one side then the other for removal. It’s basically

the same type of arrangement used for the latches

on some electrical panels.

| bow storage

cover in place |

|

|

The pictures below give a closer look at exactly

how the latch system was put together.

|

the latch

and hardware

|

|

| drawing of

the latch assembly |

|

|

The final assembly, ready for finishing...

The first step was to get the cloth and paint on

the bottom. It really isn’t much different than

applying fiberglass to a hull. Just lay out the cloth,

smooth out the wrinkles, make any tucks and darts

needed to help the cloth fit closely around corners,

tack in place with a few staples in the chines and

then apply the paint. The first coat was thinned about

20% and applied liberally with a brush. After that

soaked in and was starting to dry, I applied two more

on top of that with a couple of hours drying time

in between.

|

bow view

|

|

I masked the sides with newspaper to avoid the inevitable

drips falling from the chine logs and onto the sides,

only to be sanded off later to the detriment of the

luan veneer. I’ve never been accused of being

an overly neat worker; therefore, I try to avoid opportunities

for drips, spills, slashes, smears and any other type

of “mistake”.

I found that while it looks like three-ply stock,

it is actually five-ply (sort of). There are three

plies of some unidentified white wood of substantial

thickness and two paper-thin plies of luan on the

outside faces. You can see in the bow view picture

below where I sanded through that thin veneer on the

top edge of the bow transom and the resulting red

glue line.

| I sanded through

that thin veneer on the top edge of the

bow transom |

|

|

After a couple of coats, the weave of the cloth was

starting to fill up so it was time to attach the two

layers of 1X2 for the bottom runners.

Two sets of lines were laid out on the bottom with

a chalk line. The first was the centerline of the

runners. I drilled a series of pilot holes spaced

about six inches apart along this line for attaching

the first runner from the inside of the hull. It also

gave me a target for laying down the caulk. The second

set of lines, ¾” closer to the chine

on each side, served as a guide for placement of the

outboard edge of the runners to ensure that they went

on straight.

I ran a thick bead of caulking down the centerline

and carefully lined up the runner, allowing about

an inch of overhang at the bow. I drove a screw from

the outside into the bow transom framing, pulled it

down into place and clamped it at the transom. Then

I crawled underneath the hull and installed the permanent

screws from inside. The process was repeated for the

other runner and the ends were trimmed flush with

the transoms. The first four inches at the forward

end beveled to a thickness of 3/8”.

The forward end of the second layer was shifted back

four inches and beveled to match the bevel of the

first layer and screwed from the outside to make later

replacement easier. Then they got a coat of brown

to match the bottom.

The wales, quarter knees and foredeck got a coat

of stain, followed by three coats of spar urethane

along with the sides with light sanding between coats.

|

One of

the quarter knees before finishing

|

|

I had some white interior/exterior semi-gloss latex

enamel that I used for the interior. I added a bit

of brown latex to the white enamel to help reduce

the glare that the white enamel would have produced.

I also experimented with a splatter pattern on the

interior, to break up the monotony of the flat tan

interior

Once all the finishing was done, the hardware was

reattached and she was ready to go. The cleats

and oarlocks

were from Duckworks. The carry handles, rope and other

ground tackle came from Wal-Mart.

I also built a set of oars per Jim’s design.

I worked from a copy of his essay rather than the

Jon Jr. plans. I didn’t realize that there was

a difference until I tried rowing. The essay calls

for 7' oars while the dimensions in the plans are

for 6.5' oars. That made rowing a bit awkward, but

I managed by sliding about six inches of the square

section of the loom into the oarlocks. The nylon

locks that I got from Chuck were flexible

enough to handle it with no problem. I really only

rowed a few yards into and out of the dock area where

the water was too shallow and the plant growth too

dense to use the motor. I've since cut the original

handles off and formed new handles, shortening the

square section by about 6" and they work quite

well now.

I had hoped to launch the boat on the weekend of

June 24/25, before departing for vacation in Indiana.

But the weather here in Pennsylvania, and elsewhere

in the northeast, was just too bad for that to happen.

Although we got so much rain here that I thought I

might get to use the boat right in the street.

Vacation time…

I launched my Jon Jr. on July 2 at a lake just north

of Ft Wayne, IN. The boat handled well and my kids

and I got to do a good bit of fishing over the next

week. It was also nice going out at night to fish

or just anchor and watch the stars.

| I launched

my Jon Jr. on July 2 at a lake just north

of Ft Wayne, IN. |

|

|

I only encountered one minor problem. It seems there

were a few knots (I think I mentioned them earlier)

in the seat framing that I didn't notice during construction

and the frames couldn't take the weight. I doubled

up some 1X2 scraps that I scrounged up and was back

in business. When I got back home, I made proper repairs,

adding another 1X2 across the full width of the frames

and installing vertical supports at the center of

the frames.

|

The PA

Fish and Boat Commission rated it for

a maximum of 7.5 hp, but Jim recommends

5 hp and that should be plenty.

|

|

The PA Fish and Boat Commission rated it for a maximum

of 7.5 hp, but Jim recommends 5 hp and that should

be plenty. Besides, most of the lakes around here

are in state parks and limited to electric motors

only, so my little trolling motor will see a lot of

action.

That trolling motor got it moving at about 1.5 MPH

on “high” (according to my GPS) and 1.2

MPH on “low”. I didn't cover a large area

but it got me where I wanted to be and it’s

less work than rowing. And at that speed, I don’t

mind letting the boys have a turn at the tiller once

in a while. I'm looking for a small outboard in the

3 - 5 hp range that I can use on the local rivers.

That should get it moving at a respectable pace.

| All in all,

it’s a very nice boat and I’m

very happy with it. I literally lived in

the water for a week and showed no signs

of leaking or any other problems. |

|

|

All in all, it’s a very nice boat and I’m

very happy with it. I literally lived in the water

for a week and showed no signs of leaking or any other

problems. If you’re looking for a small boat

for fishing or just cruising around on small lakes,

you can’t go wrong with this design. I wouldn’t

hesitate to recommend it to anyone.

I’ve been keeping an eye on the classified

ads in the local paper for a “deal” on

a small outboard. I guess perseverance pays off, because

I found, not one, but TWO old outboards: an early

50’s vintage Johnson Seahorse 3 and a late 60’s

Eska 5. Now that I’ve received my copy of Max

W’s new book on maintaining old

outboards, I should be able to get them running.

And while I’m taking a break from working on

them, I can work on constructing a bimini so that

I can have some shade in the middle of the day. I’ve

already purchased the hinge

parts from Duckworks. Now all I need

is a few pieces of electrical conduit and some polytarp

and I’m in business.

Looks like it’s going to be a busy summer.

Maybe I can find time this winter to write something

up on those projects. Stay tuned…

|