Take Apart Fishing Pram

by Tom and George Fulk

excerpted from "Messing

About In Boats"

My brother George had a nice new truck

with a 6' bed, but the 6' pram he had seemed too unstable for

serious fly fishing. There is always a temptation to stand to

cast when fly fishing since it's easier to get more distance,

and you can also cast more readily in all directions. In a way

it's a self defeating situation though since, if you remain

seated to cast, you don't need to cast far. Standing just makes

you more visible to the fish and, if standing, you MUST cast

farther. The 6' pram seemed too small on some of the cold water

and large lakes along the Alaskan highway. We mulled over how

lo get a one quart boat into a one pint truck.

The answer was obvious and I drew up

a plan for a 9' boat made of two parts, a 3' bow section and

a 6' stem section. The two part boat turned out to have an unanticipated

advantage. The two sections are each light enough lo handle

easily, but a one piece 9' boat would have been too heavy for

easy handling, especially if car topping.

George has had plenty of experience

in boatbuilding and made a few changes from the plan to ease

construction. He will tell you about this.

Construction: Tom

supplied helpful construction tips. This boat is very easy to

build. I began by ripping a 4'x8' sheet of 1/4" ocoume

plywood lo make two 2' wide sheets. I scarfed a 2'x2' piece

to the end of each, using the Payson method, to make material

2'x10' for two sides.

Next I laid out the sides following

offsets from Tom's plans, and used a batten to get a nice curve

to the bottom close to the layout lines. Having cut out one

side, I clamped it to the other and used it as a pattern for

the second side.

I built the bulkheads and transoms about 2"

too tall, laid them on the sides at the places indicated in

the plans, then marked off the bevels for the bottom and top.

I cut the bevels on a table saw. Next I notched out places in

the cross members for the chine logs, screwed and glued chine

logs to the inner faces of the sides, then attached sides to

transoms and bulkheads. The two bulkheads are installed about

3' aft from the bow and only 1/4" apart from each other.

Temporary spacers were used to maintain the 1/4" spacing

between bulkheads and the two bulkheads were installed as one

assembly. I added gunwales, laminating two pieces to make finished

wales 1-1/2" x 2".

I placed a full sheet of plywood on the lower

edge of the sides, clamped it "in place, marked off the

size, and cut it out for the bottom. I scarfed a second piece

to the first to form the completed bottom, which can just barely

be taken from one sheet of plywood. Next I added the deck to

the bow and knees to the stem. The knees reinforce the side

and transom connection and need to be fitted and fastened well.

I taped the chines with fiberglass set in epoxy. At this point

the boat looked almost finished, but the fun part was about

to begin.

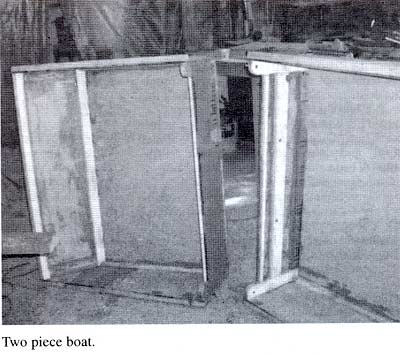

I turned the boat over and drilled four holes

through both bulkheads for the bolts. Then I took a hand saw

and cut the boat in two, sliding the saw between the two bulkheads.

That was the first time I cut a boat in half. Suddenly it took

up a lot less space in the workshop.

Next I added the seat and oarlocks. To strengthen

the holes for the bolts which hold the two parts of the boat

together, I added small stainless steel plates around the holes

to both sides of the aft section and lo the forward side of

the forward section. The 1/4" carriage bolts are permanently

glued into the forward section. I used small brass wood screws,

countersunk into the plate, and glue to hold those plates in

place. They prevent the bolts from enlarging the holes when

taking the boat apart repeatedly. Tom suggested reinforcing

the holes by gluing copper tubes into the holes. That would

have worked, too, I am sure. I buttered up the inside of the

holes with epoxy to prevent water from soaking into the end

grain. The holes need to be 1/16" larger than the bolts.

The bolts are above the water line so there is no worry about

leaks.

I placed three 3/4" x 1" cedar

runners along the bottom and covered each with a flat aluminum

strip. They do a lot to strengthen and protect the bottom from

wear. It would be best to laminate the runners for the forward

section from 3/8" thick stock so they would bend more easily

and conform to the curvature of the bottom. I painted the boat

with a one part epoxy paint, Brightside by Interlux. It took

three quarts, including undercoat.

Following Tom's advice, I built 7-1/2' oars

for this boat. They were easy to build, inexpensive, and work

well. The blades are 1/4" ocoume plywood covered with fiberglass,

set in a slot in the looms. The looms are

laminated from a clear 2"x6" ripped lengthwise. They

are finished round about 2" in diameter at their inboard

ends, tapering down to almost nothing at the blade end.

Sea Trials:

I took this boat on a two week camping trip around Lake Superior,

using it almost every day. I think the boat offers a practical

solution to the person who wants to carry a 9' boat inside a

6' pickup bed. That said, it would be better to have a 8' single

piece boat in a 8' pickup bed. It takes five minutes to put

the boat together and another five to take it apart again, so

I lose 10 minutes of fishing.

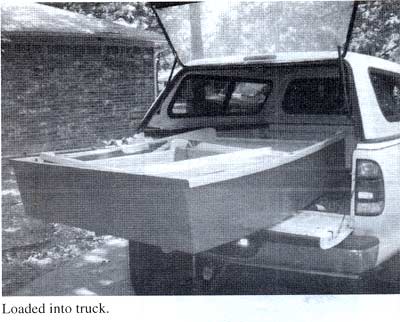

I was a bit skeptical

about how easy it would be for one person to load this boat

into a pickup. Once I got a system, I found it was really quite

easy. To load the boat, I take it apart and set the forward

end of the larger section on the tailgate. The larger piece

weighs a little less than 60 lbs., but I am lifting only one

end at a time. With one end on the tailgate and the other on

the ground, I place the smaller section of the boat into the

larger. The smaller weighs 27 lbs. Now I lift the whole thing

up and slide it in.

Once the boat is together

and on the lake, it is a wonderful fishing platform. It moves

along nicely with the big 7.5' oars. These oars have long, narrow

blades (36"x4"J, and once I get the boat moving I

can keep it moving with little effort. To give the oars a little

more clearance over my knees, I added 3/4" thick oak pads

to the gunwales and mounted the oar locks on them. The boat

is stable. I can stand up to cast, move to the side to net my

fish and to either end to lift the anchors. It is a safe boat.

I have a styrofoam block under the seat and 1-1/2" thick

foam panels along the sides. The flotation is covered with fiberglass

cloth and tied firmly in place. The styrofoam has the volume

to displace 85 lbs. of water.

This boat is designed

to be for one person but I found that, with a few modifications,

I can take a passenger. I built a small box seat that conforms

to the bottom of the forward section with a notch to fit over

the lower frame of the bow transom. I added 1-1/2" thick

pads to the gunwales of the smaller section where the sides

meet the bulkhead. The pads strengthen that joint and provide

an elevated mounting for a second set of oar locks. The boat

is nicely balanced with the passenger setting in the stem and

me rowing in the bow. My wife and I made a circuit of four lakes

in Canada, pulling the boat on a two-wheeled dolly over the

portages.

I suppose I could

put a small 2hp motor on this boat, but I am content to row

it. The gently slap, slap of the waves hitting the bottom as

I row upwind would become a terrific pounding if under power.

A Final Note:

Flotation in smalt boats used mostly in cold water is essential.

It should be securely and well placed. Hypothermia is always

an issue in trout fishing since water temperatures are seldom

over 55" and frequently in the 40s. It's best, I think,

to have a boat which will float level, into which you can slither

if the worst happens. Boats like this will seldom overturn even

though they may fill. The most common accident is falling overboard.

Getting your body out of the water even a little enhances your

Survival chances. Having offered this bit of sermonizing, let

me add that my favorite trout fishing boat has no flotation.