I have never had any formal training in outboard

mechanical work. All of my "education" in that field has come from the

"school of hard knocks."

Well, a few weeks ago I earned some "extra credit"

and it cost me dearly.

I had trailered my 1957 aluminum Crestliner boat and 1940

Johnson 22 hp outboard over to Pomme de Terre Lake in Western

Missouri

to attend a two-day meet of the Antique Outboard Motor Club. As I readied and lauched the boat

it was pretty evident that I had one of the best looking boats there,

an observation that pleased me to no end. I climbed aboard,

cranked-up the outboard and motored out of the marina area and

proceeded to "burn-up" the lake.

After all of about 5 minutes of zipping across the water the

boat suddenly began to slow as the engine began to rattle

in an odd way. Turning to look at the engine I could see

the exposed plywheel wobbling from side to side as the

engine died completely. My first thought was that the

crankshaft had broken, but an immediate examination showed

that the flyheel nut had loosened and the flywheel had literally

"flew": Coming completely loose from the crankshaft, only

gravity had keep this 15 lb. metal disc from flying-off

into the lake.

Actually, the flywheel might as well have gone into the "drink,"

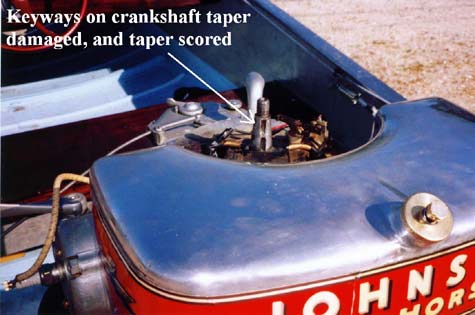

as the damage it did was quite extensive. Outboard flywheels

have a tapered bore and sit on a matching taper machined on

the top of the crankshaft. A rectangular metal "key" engages

precision-machined slots in both the flywheel hub and also on

the crankshaft in order to lock the flywheel into a certain position

on the crankshaft.

When my flywheel came loose (at about 4000 rpm) the key

badly damaged the keyway (slot) machined into the crankshaft,

and totally destroyed the hub of the flywheel. In order for this engine

to run again, I will probably need to obtain a replacement flywheel

(obviously not available new) and the crankshaft would need to undergo

some serious machine work. As I have another 6 or 7 of this model

engine, most likely I will just keep the "dead" one for replacement

parts for the others.

I thought I had learned to keep the flywheel nut tight from the many

stories of others who have experienced this misfortune, but evidently

it was a lesson that I had to learn the hard way. With the totally-exposed

flywheel, the nut was staring me in the face every time I wrapped a

rope around the flywheel to start the engine. To pick-up a wrench

and put it on the nut would have taken all of 10 seconds.

Learn from my mistake; make it a habit to put a wrench on your outboard's

nuts and bolts every so often to insure that they are tight: especially

the flywheel nut.

Max