Kill or be Killed

Perhaps you have seen the tapes on "Funny Home Video"

television shows; the riderless powerboat circling at

high speed until it rams another boat or a rocky shore, as

it's operator, who was thrown from the boat (usually while

doing something stupid) watches helplessly.

Sometimes it's not so funny, as the "authorities" remove the

body of the operator from the water after the circling boat

ran him down, or even more tragically, remove the body of

an innocent bystander who was run-down by the uncontrolled

speeding boat.

Nearly all modern outboard motors are fitted with a safety "kill-

switch." which has a lanyard that the operator attaches to his

person. Then, if the operator parts company with the boat, the

lanyard is pulled and the engine shuts-down. This is a safety feature

well worth having, and it can be easily installed on the older OMC-built outboard motors that I recommend so highly as a source of

cheap power. This would be OMC-built engines manufactured

from about 1955 until about 1972, and of 40 hp and less. All of

these engines, most of which are two-cylinder, are fitted with

simple "points and condenser" ignition that is vary adaptable

to lanyard safety switches.

It will allow you to "kill" the engine before the engine can kill you.

Or someone else.

click images to enlarge

click images to enlarge |

The addition of such a "kill switch" is dirt-easy if your old OMC engine

was originally fitted with a push-button shut-down switch. Have a look

at the posted Johnson Service Bulletin, which explains how the

standard push-button stop-switch worked. Basically, it is just a spring-loaded

switch, "normally open" (normally in the "off" position) that is connected

by two wires to the ignition points. The magneto ignition system on

these two-cylinder OMC engines is always "on:" in order to turn the

ignition "off," an electrical connection is made between the ignition

points of both cylinders. This disables both cylinders and the engine

stops running. One pushes the stop switch, the stop switch electrically

joins the two cylinder's ignition points, and the engine stops.

If your engine was not originally fitted with the "push to stop" switch,

the lanyard kill switch can still be added; it is just a little more

work.

If your engine was not originally fitted with the "push to stop" switch,

the lanyard kill switch can still be added; it is just a little more

work.

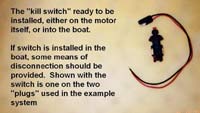

The main item one needs in order to install the safety kill switch is, of

course, a kill switch. These are available through boat dealers and also through

many mail-order and on-line marine suppliers. The important thing to

remember is that you need a switch that is "normally open;" usually this

type of switch is specified as a switch for magneto ignition systems,

but ask questions if you are not sure.

Once you have your switch, you need to decide if you want to mount it

to the engine, or mount it to the boat. Mounting the switch to the engine

keeps one from having to run wires on the boat, and makes it very easy

to transfer the engine to another boat. However, chances are you will have

to fabricate some sort of bracket to mount the switch on the outboard motor,

which might be more work than wiring the switch, plus the bracket may

not look "nice," if you are concerned about aesthetics. Finally, you really ought

to purchase a spare lanyard so that, if you are pitched from the boat,

someone remaining in the boat can attach the spare lanyard to the motor,

allowing it to be restarted so the boat can circle back to pick you up.

Once you have your switch, you need to decide if you want to mount it

to the engine, or mount it to the boat. Mounting the switch to the engine

keeps one from having to run wires on the boat, and makes it very easy

to transfer the engine to another boat. However, chances are you will have

to fabricate some sort of bracket to mount the switch on the outboard motor,

which might be more work than wiring the switch, plus the bracket may

not look "nice," if you are concerned about aesthetics. Finally, you really ought

to purchase a spare lanyard so that, if you are pitched from the boat,

someone remaining in the boat can attach the spare lanyard to the motor,

allowing it to be restarted so the boat can circle back to pick you up.

Mounting the switch to the boat means than one switch can serve several

engines when used on that boat, each engine being fitted with a disconnect

plug on the wiring. Also, in the event of "man overboard," the disconnect

plug can be disconnected, rendering the switch inoperative and allowing

the engine to be restarted to go back and pick up the jetsam. However,

if the connecting plug should vibrate loose or should you simply forget to

plug it in, the safety switch is rendered equally inoperative.

Mounting the switch to the boat means than one switch can serve several

engines when used on that boat, each engine being fitted with a disconnect

plug on the wiring. Also, in the event of "man overboard," the disconnect

plug can be disconnected, rendering the switch inoperative and allowing

the engine to be restarted to go back and pick up the jetsam. However,

if the connecting plug should vibrate loose or should you simply forget to

plug it in, the safety switch is rendered equally inoperative.

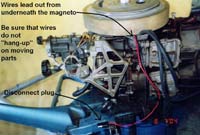

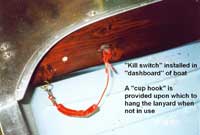

The example installation shown here has the switch mounted in the "dashboard"

of the boat. A trip to the Radio Shack store resulted in the purchase of

a low-voltage "power cord" measuring about 3 1/2 feet in length, and featuring

matching two-prong plugs at either end and also an "in-line' fuse holder.

Cost was about $2.00 plus sales tax. One could certainly use fancier plugs, but

I preferred to go "cheap." The wire was cut in two, and the fuse holder

thrown in the "junk' box for use on a later project, and I now had my disconnect

plugs. As the example engine (the 1953 Evinrude "Big Twin" featured in the

latest "Start to Finish" column series) did not have the existing stop switch, I had

to add the necessary wiring. The magneto was removed from the engine

(see Magnetos column) and two small holes (about 1/8 inch) were drilled through

the bottom of the magneto plate near the ignition points. Be careful not to

drill through anything besides the plate. Also be aware that the wires you add

must not be in the way of moving parts underneath the plate; remember that the

plate rotates to provide "spark advance."

The example installation shown here has the switch mounted in the "dashboard"

of the boat. A trip to the Radio Shack store resulted in the purchase of

a low-voltage "power cord" measuring about 3 1/2 feet in length, and featuring

matching two-prong plugs at either end and also an "in-line' fuse holder.

Cost was about $2.00 plus sales tax. One could certainly use fancier plugs, but

I preferred to go "cheap." The wire was cut in two, and the fuse holder

thrown in the "junk' box for use on a later project, and I now had my disconnect

plugs. As the example engine (the 1953 Evinrude "Big Twin" featured in the

latest "Start to Finish" column series) did not have the existing stop switch, I had

to add the necessary wiring. The magneto was removed from the engine

(see Magnetos column) and two small holes (about 1/8 inch) were drilled through

the bottom of the magneto plate near the ignition points. Be careful not to

drill through anything besides the plate. Also be aware that the wires you add

must not be in the way of moving parts underneath the plate; remember that the

plate rotates to provide "spark advance."

The wires were then feed up through the holes and the ends of the wires were fitted

with crimp-on ring terminals. Then the wires were attached under the screws on

each set of points, the small screws which also hold the wires from the coils and

also the wires from the condensers. After this 10 minutes of work, the magneto was

ready to be reinstalled on the engine.

The wires were then feed up through the holes and the ends of the wires were fitted

with crimp-on ring terminals. Then the wires were attached under the screws on

each set of points, the small screws which also hold the wires from the coils and

also the wires from the condensers. After this 10 minutes of work, the magneto was

ready to be reinstalled on the engine.

Be sure to rotate the magneto through the full range of it's rotation to be sure that

the wires will not interfere with it's movement. Then route the wires out of the cowling

at some convenient place and the engine is done.

If your engine is already fitted with a push-button stop switch, all you have to do is

disconnect the wires from the push-button stop switch and attach the wires to

a quick connect plug, or in the case of a motor-mounted safety kill switch,

connect the wires directly to the kill switch. This will render the "push to stop"

switch inoperative, but you can always pull the lanyard to stop the engine.

If your engine is already fitted with a push-button stop switch, all you have to do is

disconnect the wires from the push-button stop switch and attach the wires to

a quick connect plug, or in the case of a motor-mounted safety kill switch,

connect the wires directly to the kill switch. This will render the "push to stop"

switch inoperative, but you can always pull the lanyard to stop the engine.

There is no need to remove the flywheel and magneto if the "push to stop"

switch and wiring is already present.

The example switch was installed in a round hole drilled in the dashboard of the example

boat, and then two wires lead from the switch back to the transom, said wires being

soldered to the wires on the "other half" of the Radio Shack power cord to provide

the "boat end" connector plug to attach to the connector plug on the motor.

The example switch was installed in a round hole drilled in the dashboard of the example

boat, and then two wires lead from the switch back to the transom, said wires being

soldered to the wires on the "other half" of the Radio Shack power cord to provide

the "boat end" connector plug to attach to the connector plug on the motor.

And that is all there is to it; be sure to thoroughly test your new safety kill switch, and

as mentioned before, give some thought as to how the engine can be restarted

without the lanyard being present, and in the case of the boat-mounted switch, give

some thought to the possibility of the switch being accidentally disconnected.

And that is all there is to it; be sure to thoroughly test your new safety kill switch, and

as mentioned before, give some thought as to how the engine can be restarted

without the lanyard being present, and in the case of the boat-mounted switch, give

some thought to the possibility of the switch being accidentally disconnected.

By the way, if you are running a single-cylinder engine, you connect one wire to

the single set of ignition points, and the other wire to a "ground" on the engine.

That is how I how I made the connection to my 1940 22hp Johnson, which does

have two cylinders, but both cylinders "fire" simultaneously from a single set of

points.

Wishing you safe motor'n!

Max