SHARK GUARD

I look everywhere for good boat building tools for you readers. As a point I try not to write about tools that don’t work or that work poorly. It saves space and face so if you are thinking about a tool and you want an opinion you can email me. There are so many wonderful tools out there I can fill many pages without being overly negative. My miter saw review was an exception and unless you readers want more articles like that one I will try to do individual tools. So now I can get to the meat of this review. Have you ever heard of a shark that protects humans? Well I will tell you about it and its many functions.

I am a Ryobi BT3100 Table Saw fan. I sometimes read posts from the BT3 Central forum where other Ryobi fans post about particular products they like. https://www.leestyron.com/ There I read about a custom hand made quality saw Guard for the BT3000 series Ryobi saws. Not only is it hand made by a master craftsman but he can customize the finish to any color combination you could ever want. It seems that others beside myself found fault with the riving knife and its spurs on the BT series table saws. Not only that but when you add a zero clearance throat plate to the saw it would spew half of the sawdust on top of the table. That in turn would make for a huge cleanup problems.

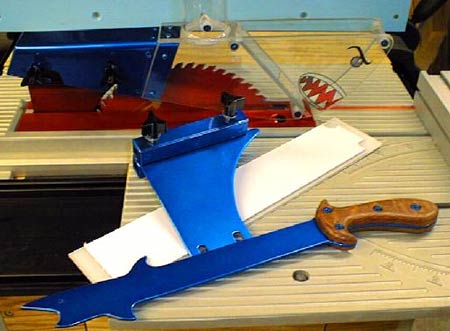

Now a very crafty inventor by the name of Lee Styron decided that he would design a fix for the riving knife and the saw dust problem and then the Shark Guard was born. Besides being very talented Lee has a touch of humor in his bones and mounted a sharks face on this brand new Shark Guard design. As you can see from the photo above, the guard has a vacuum attachment on it’s top. In the photo below, you can see the Guard mount on top of the new design riving knife.

What a joy this new set is to use on my saw. I know for a fact that it could be modified to fit nearly any type of table saw. Lee is experimenting with another brand saw now and I am sure new mounts for others will follow. The new knife works much better and doesn’t leave marks in the wood like the old prawls did on the stock Ryobi unit. In fact the new design has omitted the prawls all together. He has made a large stop that also acts as a mount on the riving knife. Doing so stops the wood from climbing the blade and stops the resulting wood kickback. Anybody that has experienced one knows that it can harm or even kill an unlucky wood worker.

I called Lee and asked if he would submit one of these Guards for review in this magazine. Soon a postal package arrived at my door and when I opened it I was amazed! The quality of the workmanship was fantastic. These are truly hand crafted custom attachments for your saw. All of the metal was finished and the powder coating looked better than most factory jobs. The lexan is held together with polycarbonate dowels adhesive and stainless screws. It is a very sturdy Guard and I can attest to its strength as I accidentally stepped on it in my shop. It held up under the weight of my twenty seven acre body. If it can do that then it must be very strong. I had an arm load of things including the Shark Guard and I set them down to unlock my shop door. I bumped the box with my foot and stumbled with my full weight landing on the Guard. Lee makes a great attachment and it didn’t even scratch the powder coating!

I have used this guard with many different types of blades and the top of the table stays very clean. Unlike the stock unit that would cover the table top with sawdust and make large prawl marks It is much safer now because I don’t have to reach near the blade to remove the prawls that made the wood impossible to pull back through. I think everyone who owns a table saw should get a Shark Guard.

Go to Lee’s Web Site and see the different color combinations he can use to build your custom Shark Guard. He also has a very nice custom push stick he calls a Shark Feeder that he can color match to your Guard.

I have reviewed dust Guards that are twice the money and don’t do the job better than Lee’s invention. The whole Guard with the feeder and a cherry custom color job is only $120.00! I have spent that on one saw blade before. Lee has different prices for different packages and I can assure you these are handcrafted works of art! When was the last time you bought a hand made tool? When have you ever picked the color of something that costs under $15,000? Not since Mr. Biesemeyer sold his Great Saw Fence from shop to shop have I seen a super idea take shape in a small home shop. Believe me this Shark Guard will make you a better boat builder with the difference in the way your saw fence works. If you have purchased a BT 3000 or a BT3100 there is no greater performance enhancer than this Shark Guard for the money.

I plan on giving my Brother in-law a BT 3100 saw as a house warming gift since he just bought a new house. I am going to put on a Shark Guard before I take it to him so he can have the use of such a great hand made attachment. My brother in-law is a fine craftsman in his own right and he makes everything he works on with great pride. I know he will like the convenience of the Shark Guard when he starts remodeling his new home. He is the only human on earth that I know who can make a custom banner with fine calligraphy and never measure anything. In fact he can judge the size of the letters and they fit onto an already cut banner with the borders the same size at the end that it was at the beginning. That is a perfect eye in my book. With a person of that great talent I would not want to give him something that was not the absolute best. That’s why his saw will have a Shark Guard.

Lee Styron has the same eye for fitting and detail as my brother in-law. On my next trip to the east coast I’ll try to drop by Lee’s shop to see exactly how he makes each Shark Guard he builds. Lee first thought of the safety factor and designed a riving knife to stop kickbacks but he was not satisfied with only doing that. He then tackled the problem of the saw dust from the zero clearance throat plates. Then still not satisfied he decided that anybody should be able to pick the custom color that they wanted since he mastered the powder coating process.

So here is his contact information: