Hello Chuck! Thought I would send you this series of photos

of the two Larsboats

that I decided to build.

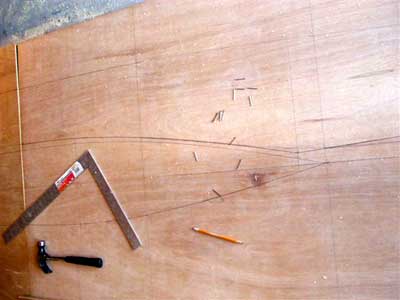

The first two photos shows (2) 8x4 5 millimeter

meranti sheets just butted together and held with some duck

tape underneath to stop them from moving.

This shows the 30 inch stretch from the Toto

and as the dimensions are the same, the lofting batten is held

flat by the square.

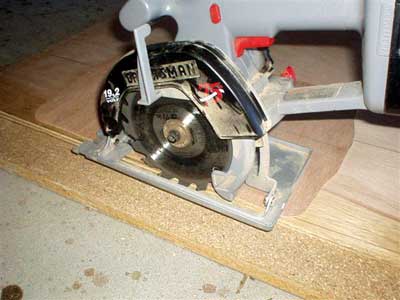

I use a 3/4 inch particle board 8x4 laid on

the floor as my cutting base.

8x4 panels laying on the "sacrificial

" particle board as I am making 2 boats at the same time.

This shows the depth setting on the saw by

placing a 1/8 inch scrap of ply under the base of the saw and

then dropping the blade onto the particle board. When you cut

the panels the saw blade will be just 1/16 inch below the depth

of the panels.

cutting to the lofting line (everybody should

invest in these cordless saws, they are wonderful to use).

the cuts in progress.

using the cut panels to mark out the mirror

images.

all that is left from a pair of 8x4 sheets.

The bow sections of the lars boat cut out.

All that is left is the stern section and will follow the same

sequence. Then stack the pieces together and belt sand them

to a fair curve.

Bow Sections

This set of photos shows the final stitching of

the Larsboat

Bow section. This is the first time I have used plastic ties,

always used copper wire before (and have the marks to prove

it!) the ties worked so much better , easy and cheap , I hope

I can pull off building this boat in 2 parts then fixing the

2 halves together , Its so easy to work on a small section at

at a time, we shall see

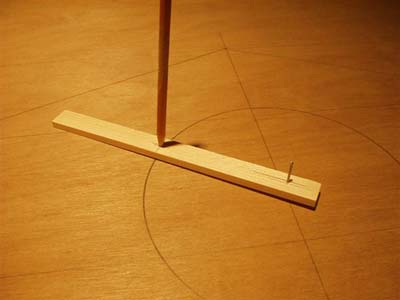

A poor mans compass

Placing temp form in bow (in fact this will

stay in boat and will I add flotation to the forward compartment)

First mark position of bulkhead and drill just 2 sets of stitching

holes , then zip tie and snug up tight

Marking the bottom panel and chine panel for

the stitch holes by holding the chine in position

The rest of the photos show the shear panels

in position and all zipped up ready to epoxy the inside seams

Stern Sections

Had a busy weekend. I have another batch of photos

for you.

(Spot welding) with epoxy the panel edges between

the ties so that the ties can be removed when the epoxy goes

off and apply epoxy to the small area that is left. This spot

welding is remarkably strong and will hold the boat together

if you handle it carefully.

The next photo shows the panels laid out on my sacrifical 8x4

sheet and marked and drilled for the stitch holes.

This is the way I line up the holes when the panels diverge

from each other

I found this the best way to stitch up the panels by standing

them up and placing 2 or 3 stitches just so the panels stay

up on their own. Then it's quite easy and fast to place the

rest of the ties. I just snug them up at this stage.

The next photo shows the panels during stitching. This went

really fast and no stooping or bending.

This is the Transom panel and my way of overcoming

the beveled edges that are often required. I used 1/2 inch material

for the Transom and then rounded the inside edge with a 1/4

round overcutter in the router. This allows the side panels

to sort of roll to the right position on the Transom.

Using a nail as a drill (a nail chucked into

a drill makes a excellent drill bit) I positioned the Transom

and drilled thru the panel into the Transom and then tapped

the nail ( the same nail size as I used as a drill bit) to secure

the panel to the Transom.

The rear end with the Transom in position.

I set the ties nice and tight and all that is left is to epoxy

it in postition and an area about 12 inches forward to make

it nice and strong.

The next job will be the forward bulkhead done

the same way. Having a round inner edge to this panel means

a lot of the epoxy ( the fillet) can get between the two panels

a strong joint .

Shows the two stern sections of the Lars boat.

Also 004 the two bow sections epoxied and drying

in the sun.

Regards, Steve

Dandridge