Canal

Boat

design by Roger

Schroeder

(plans coming soon)

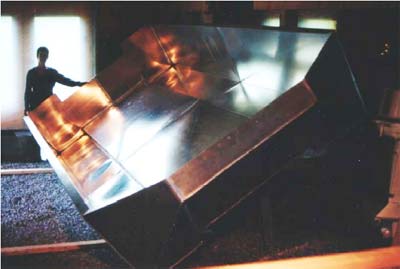

Welded 5052 aluminium hull being

rotated upright the shape is based on

two break-formed sections (see drawings). Pre-forming the sections

eliminates the need for framing during fabrication.

Aluminium was my material of choice

because of its resistance to destructive corrosion and rot. This

boat will be in the water all season a muddy creek (Ransom Creek)

that flows into Tonawanda Creek which is a section of the Erie

Barge Canal near it terminus in Buffalo, NY.

These are the internal frames

that will provide hull stiffiness. The knee in the frame is intended

to stiffen it an become seating supports. They are made of fir

2x4’s screwed and glued. They are then coated with a waterbase

interior polyurethane because they will remain protected from

the elements.

Leak testing the hull with 8”

of water. Minor leaks are found and marked the hull drained and

the welds corrected. Waterline welds are primed to provide additional

insurance to leaks. In three years the only water in the boat

came from above.

Frames installed in hull and attached

to welded brackets (not seen in

photograph)

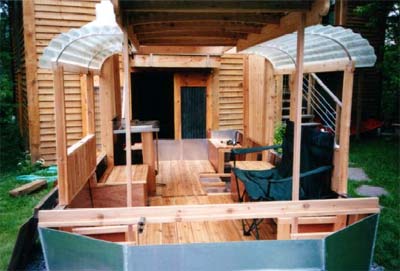

Interior construction of cedar

decking and Luan underlayment all sealed with the interior waterbased

polyurethane. Decking is held in place with stainless steel screws.

Boat side solid sections are tounge in groove western red cedar.

Now moved out to finish construction

because of limited ceiling height. Center section of the roof

is framed in cedar and covered with galvanized corrugated metal.

Sides of the roof are clear fiberglass corrugated panels fastened

to aluminium ribs.

First season in the water without

windows but sitll giving creek tours on a

trolling motor.

Winter berth showing how it is

left all winter.Exterior wood is coated with

Cuprinol |