How

I built my Seagull

by Paul Groom

Seagull

- 15' 3" rowing dory - designed by John Welsford

I have never built a boat before,

the inspiration came when we moved to a house near a local inner

harbour beach in Auckland NZ. I had a big empty shed, some spare

time, a three year old son and summer round the corner

A

friend showed me plans for John

Welsford's light dory, it looked pretty simple and practical,

but after a call to John he suggested his Seagull which has a

bit more room for the family. I had to wait a bit for the plans

as John is a busy man, so if your letterbox is empty dont despair,

they will arrive in time! John is also very helpful if you have

a problem, many thanks to him for his support. His website is

at time of writing still being finished but its a great place

to have a look at what he's up to. A

friend showed me plans for John

Welsford's light dory, it looked pretty simple and practical,

but after a call to John he suggested his Seagull which has a

bit more room for the family. I had to wait a bit for the plans

as John is a busy man, so if your letterbox is empty dont despair,

they will arrive in time! John is also very helpful if you have

a problem, many thanks to him for his support. His website is

at time of writing still being finished but its a great place

to have a look at what he's up to.

I

have a Triton sawbench, the kind where you fit your power tools

into (better than nothing but annoying unless the circular saw

you use is big and strong), a sander, jigsaw, drill and an odd

collection of handtools. My previous building experience is next

to zero, handicapped by pigheadedness disguised as enthusiasm.

In other words I have a lot to learn. I

have a Triton sawbench, the kind where you fit your power tools

into (better than nothing but annoying unless the circular saw

you use is big and strong), a sander, jigsaw, drill and an odd

collection of handtools. My previous building experience is next

to zero, handicapped by pigheadedness disguised as enthusiasm.

In other words I have a lot to learn.

My

building method was to have a go first, make a disaster, fix it

up on second or third attempt and as soon as it looked remotely

passable move on. This is not the best way to get your boat on

the front cover of a glossy mag, but it is a good trade off for

learning and getting the thing in the tide vs a work of art. In

the future I would probably go a bit slower, read a few more books

and ask a few more questions. the main problem manifested in big

daggy fillets, lumpy glue lines and despair at sanding it all

back. On the bright side I kept the West people in a job! After

finishing it I found a few links to good glue techniques which

I advise the newbie to read a couple of times to save a lot of

sanding. My

building method was to have a go first, make a disaster, fix it

up on second or third attempt and as soon as it looked remotely

passable move on. This is not the best way to get your boat on

the front cover of a glossy mag, but it is a good trade off for

learning and getting the thing in the tide vs a work of art. In

the future I would probably go a bit slower, read a few more books

and ask a few more questions. the main problem manifested in big

daggy fillets, lumpy glue lines and despair at sanding it all

back. On the bright side I kept the West people in a job! After

finishing it I found a few links to good glue techniques which

I advise the newbie to read a couple of times to save a lot of

sanding.

The

more accurate your woodwork the better. I had the attitude that

epoxy cures all, true but its better to use as little as possible

to save on finishing time. The

more accurate your woodwork the better. I had the attitude that

epoxy cures all, true but its better to use as little as possible

to save on finishing time.

As soon as I got the plans I launched

into it by penciling out the bottom and sides directly on to the

ply, cutting them out and butt joining them (remember to join

the both sides from the inside!) After a bit of head scratching

I managed to interpret the frame construction and glued it all

together.

The

construction process it pretty simple and in less than three 2

hour days of cutting and gluing I had a basic boat stitched together

with electrical ties. The

construction process it pretty simple and in less than three 2

hour days of cutting and gluing I had a basic boat stitched together

with electrical ties.

After a spot of guess work I managed

to get the fillets and glass tape on, I used the 12 oz double

bias tape, you can cut cloth into strips to save a few dollars

but I chose the easy way. The next job was to glue the frames

in place and then the gunwales. I had a problem here with a glue

mix that was still chewing gum after 2 days. I got a bit worried

when West tech support said start again, however John reassured

me that it would set and sure enough after a week it was hard,

Whew! Instead of clamps I used drywall screws and did things like

putting the inwale spacers on first rather than clamping later.

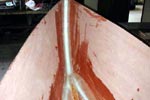

All

done and finishing time. I got a bit depressed with the mess I

had made with the glue and after many hours sanding and a couple

of attempts at fairing I gave up and decided to let the paint

"hide a multitude of sins" Of course this didnt work

but it serves as a lesson for next time. I did find though that

after a supreme effort at finishing and you dont know if you have

done enough, a coat of primer will give you an even background

to see if you work is ok, and if not a bit more fairing mix still

sticks ok. All

done and finishing time. I got a bit depressed with the mess I

had made with the glue and after many hours sanding and a couple

of attempts at fairing I gave up and decided to let the paint

"hide a multitude of sins" Of course this didnt work

but it serves as a lesson for next time. I did find though that

after a supreme effort at finishing and you dont know if you have

done enough, a coat of primer will give you an even background

to see if you work is ok, and if not a bit more fairing mix still

sticks ok.

And it floats!

The

maiden voyage was over a 5km channel to an Island in the Hauraki

Gulf, three up with 100kg of camping gear. With a 1 metre wind

chop on the quarter she handled it well. The

maiden voyage was over a 5km channel to an Island in the Hauraki

Gulf, three up with 100kg of camping gear. With a 1 metre wind

chop on the quarter she handled it well.

Not so sure of bigger nasty stuff,

but these shots are a few days later going up a local estuary

for a picnic.

The

Honda 2 horse is a great little beastie. I have nothing to compare

it to but at full throttle its a bit noisy in a thumpy way as

opposed to 2 stroke whining. No smell! and it used about 600ml

(1 pint) for about 50 minutes running. So you could safely work

on 1 litre per hour at full pelt. The

Honda 2 horse is a great little beastie. I have nothing to compare

it to but at full throttle its a bit noisy in a thumpy way as

opposed to 2 stroke whining. No smell! and it used about 600ml

(1 pint) for about 50 minutes running. So you could safely work

on 1 litre per hour at full pelt.

Under oars its a pleasure to pull

and feel the boat move sweetly away. I dont have enough experience

to make distinctions, but she rows fine for me.

And our summer is just arriving!

|