An Unconventional Boat

by Horst

Werner

(click HERE

for Folding Tri study plans)

It all began when I went sailing

with my small ballasted cabin cruiser in a 5-6 Bft. wind. A knockdown,

man-over-board and the complete inability to get the boat back

into harbour without help left me so scared that I didn't dare

to go out on that boat with my wife and my baby any more.

The safer alternative would have

been a bigger boat, about 20 feet long with a weight of at least

one ton. On the other hand, I already found the hassle I had slipping

the 350 kg boat annoying. Furthermore, such a big boat doesn't

fit well to the small and partially shallow lakes in my region,

and it would eat up lots of money for marina and maintenance.

So what did I really want? A boat

that didn't exist.

- A lightweight trailer boat, ready to sail

in about 20 minutes.

- shallow draft and beaching capability

- minimum heel even in strong winds

- capacity for up to six adults (and a handful

of small kids)

- stowage for a one-week trip

- self-draining cockpit

- unsinkability and unswampability

- a small cabin for the kids, ideally big

enough to sleep two adults

- ideally, the potential to exceed hull speed

It

was clear that only a multihull could provide the stabilty I wanted

for a light-weight trailer boat. And I think I got infected by

the multihull virus when I made experiments with my canoe converted

into an outrigger boat before buying a "real" sailboat. A catamaran

like Wharram's Tiki 21 seemed attractive, but would not offer

the comfort I had in mind and wouldn't be a real trailer boat.

As for trimarans... well there seems to be an unwritten law that

trimarans are uncomfortable racing machines with extremely slim

center hulls. It

was clear that only a multihull could provide the stabilty I wanted

for a light-weight trailer boat. And I think I got infected by

the multihull virus when I made experiments with my canoe converted

into an outrigger boat before buying a "real" sailboat. A catamaran

like Wharram's Tiki 21 seemed attractive, but would not offer

the comfort I had in mind and wouldn't be a real trailer boat.

As for trimarans... well there seems to be an unwritten law that

trimarans are uncomfortable racing machines with extremely slim

center hulls.

But what if you build something

like a cruising centreboarder with stabilizing floats? It turned

out that it would be feasible, but that a really light planing

hull would require the cockp it

to be more or less in the middle, since crew weight determines

the location of the center of gravity to a high degree. On a short

boat, there would be no way of getting a reasonably sized cabin

in front of the cockpit since the first two feet are too narrow

to be of any use. So I came to the idea of having an aft cabin

and the resulting design looked like this: it

to be more or less in the middle, since crew weight determines

the location of the center of gravity to a high degree. On a short

boat, there would be no way of getting a reasonably sized cabin

in front of the cockpit since the first two feet are too narrow

to be of any use. So I came to the idea of having an aft cabin

and the resulting design looked like this:

With a hull length of 5

m and a weight of about 250 kg it was a really small boat, but

by extending the cabin under the seat bench, it would offer 2m

berths and a 1,80 m cockpit right in the middle of the boat. A

20 cm layer of styrofoam in the bottom and two drain pipes would

ensure that the boat can't be swamped or sink.

And a sophisticated folding

mechanism including floats rotating by 180° would reduce the width

from 3,50 m to 1,90 in a few minutes.

|

|

|

I submitted the design to Duckworks Magazine's

2000 design contest. It earned me a honourable mention (thank

you, Chuck!), but the reader's poll was, well, desillusioning.

But hey, I was the only person who needed to like it. So I

prepared myself to build my boat. |

I bought the plywood and a used trailer in spring 2001. Unfortunately

the trailer was a bit to short for the boat, but I thought I could

get away with it if I shortened the boat to 4.70 m. At the same

time, my wife stated clearly that she would not sleep in such

a small boat, and thus the aft cabin became obsolete. I changed

the design by doing two straight cuts through the given hull lines

(my father had already made the stem and I didn't want to throw

it away): I cut off the last 30 cm and the top structures.

I bought the plywood and a used trailer in spring 2001. Unfortunately

the trailer was a bit to short for the boat, but I thought I could

get away with it if I shortened the boat to 4.70 m. At the same

time, my wife stated clearly that she would not sleep in such

a small boat, and thus the aft cabin became obsolete. I changed

the design by doing two straight cuts through the given hull lines

(my father had already made the stem and I didn't want to throw

it away): I cut off the last 30 cm and the top structures.

With the new straight deck line,

the platforms could fold 180 degrees, so the floats didn't need

a rotating mount any more. In the changed design there is still

enough space for the children under the foredeck and they can

even sleep under the aft deck.

Now the actual construction was

a very long process since my wife wouldn't let me invest all my

spare time in the boat. In fact, without the help of my father,

my brother and my sister, I would never have finished the boat

(I think my father put twice as much time into the boat as I did).

We started in summer 2001, and maybe we spent more time talking

than actually working, but it was well worth the time.

The following pictures show some

stages of the building process:

Since the hull is made from Okoume, we

glassed almost every part of the surface (they say it rots really

fast). Although I always used latex medical gloves, I finally

got allergic against epoxy. My hands appeared like cauliflower

and itched for two weeks! In March 2002, we had to get the boat

out of the workshop, which was not easy since the workshop was

in the basement. Here is how we did it:

In July 2002, the main hull was finished

and we made the maiden voyage with a trolling motor on a nearby

lake. We were six adults and three kids and we didn't feel cramped.

The main alone is already very stable and you feel safe in it.

But I didn't want a motor boat... so I went ahead. The floats

were glued together of 1m x 0,5m x 5cm styrofoam plates with a

3 cm bottom of blue foam. Then the project was waiting till April

2003, when I started taking regularly single days of vacation

in order to visit my father and work on the boat. We shaped the

floats mainly by clamping plywood templates to both sides and

then drawing a hot wire along the plywood edges. It worked very

well and only about an hour was needed to bring both floats to

the final shape with a disc sander.

We laminated them with

two layers of 200 g/m^2 glassfibre. Although I used thick rubber

gloves, protective paste and wore a gas mask, I got an allergic

reaction on the hands again. Maybe it was due to walking in the

room without gas mask after the work was done. It is really hard

to have that allergy if you're bitten by the boatbuilding bug!

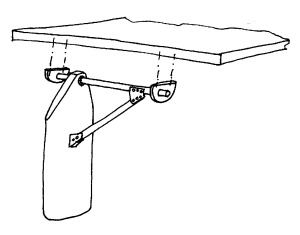

The

leeboards are very unconventional too: They hang under the platforms

and pivot around an axle made of 1" aluminium tube that runs crosswise

through their top an is glued in with epoxy. A diagonal strut

which is bolted to the leeboard just above waterline forms a triangle

together with the leeboard and the axle which can cope with the

high bending momentum. The

leeboards are very unconventional too: They hang under the platforms

and pivot around an axle made of 1" aluminium tube that runs crosswise

through their top an is glued in with epoxy. A diagonal strut

which is bolted to the leeboard just above waterline forms a triangle

together with the leeboard and the axle which can cope with the

high bending momentum.

The proper leeboard is mostly

hollow and approximates a NACA012 profile. Each is made by bending

two 5mm plywood sheets around a center strip and glueing them

to a trapezoidal "nose strip" and a triangular "tail strip". Next

time I'd take 3 or 4 mm plywood since the bending required really

high forces.

Cross section of

leeboard (and no, it's not meant to be asymmetric)

The leeboards are glassed

on the outside so that they are very strong and very light - they

must be held down in the water against their buoyancy by strong

rubber bands pulling them forward and a rigid line running aft.

The lines end has several knots and is led through a U-slot so

that its length (and thus the position of the leeboard) can be

easily adjusted.

The platforms are also

sandwich structures with a 40 mm styrofoam core in a lumber frame

and two 5 mm plywood sides which are additionally glassed with

200 g/m^2 fabric. Each platform complete with the float weighs

about 25 kg. So the boat is at least 50 kg heavier than a 16'

unballasted monohull dinghy.

The

mast was a gift from a friend and has formerly been used on a

505 dinghy (as far as I know... with only 4,80 m it's suspiciously

short). To save time, I used the sails of a small fishing dinghy

I had a chance to buy really cheap. They fit well to the short

mast... but they have only 7.5 square meters, that is only half

the area in my plans. Well for first trials maybe not a bad idea.

To avoid jibe-caused headaches, I mounted a surfboard's sprit

boom instead of the boom belonging to the mainsail. The

mast was a gift from a friend and has formerly been used on a

505 dinghy (as far as I know... with only 4,80 m it's suspiciously

short). To save time, I used the sails of a small fishing dinghy

I had a chance to buy really cheap. They fit well to the short

mast... but they have only 7.5 square meters, that is only half

the area in my plans. Well for first trials maybe not a bad idea.

To avoid jibe-caused headaches, I mounted a surfboard's sprit

boom instead of the boom belonging to the mainsail.

The mast is stayed by two aluminium

tubes which lead lateral forces directly to the floats and two

additional galvanized steel stays which should only transmit the

forward-directed parts of the sail force.

Finally the day came when everthing

was finished and we went off for a two-day trip on a lake in France.

The boat can be folded and unfolded by one person if necessary,

but setting the mast up is easier with two persons. The whole

setup takes about 20 minutes after a bit of training.

Mid of October is maybe not the best

time for such a trip, but after all that work we wanted to try

it out! It was only 11°C, but we had sun and wind. Lots of wind,

I estimate 4-5 Beaufort. The trolling motor could hardly cope

with the boat under these conditions and I felt really uncomfortable

when we set sails...

After

half an hour of completely upright sailing under full sails,

I got more confident. The boat behaves very well, it tacks on

a dime (having a boom at the foresail and the lack of necessity

to change sides makes tacking a pretty negligible manoevre)

and even when beating upwind against some nasty waves the cockpit

stays dry (apart from occasional drops). As for speed, we probably

went at hull speed most of the time but didn't get her to plane.

We'll see what happens with 15 square meters of sail. After

half an hour of completely upright sailing under full sails,

I got more confident. The boat behaves very well, it tacks on

a dime (having a boom at the foresail and the lack of necessity

to change sides makes tacking a pretty negligible manoevre)

and even when beating upwind against some nasty waves the cockpit

stays dry (apart from occasional drops). As for speed, we probably

went at hull speed most of the time but didn't get her to plane.

We'll see what happens with 15 square meters of sail.

A really useful feature is the "hawse hole"

mounted to the bowsprit. It allows to let the anchor hang from

the bowsprit all the time, with the chain in a box in the upper

part of the bow. So you don't get dirt into the boat and the

anchor can be dropped very quickly.

But still better than anchoring

is beaching! We went ashore at the lee side of an island, collected

some wood and prepared a barbecue. Maybe beaching is actually

the best part of sailing... at least when it's cold and windy.

I know that now a long phase of tinkering

with experimental sails and improving details begins. But the

boat already meets my expectations completely, I only think it

was too much work (estimated 400-500 hours). If I had to redo

the design, I'd leave out the styrofoam double bottoms, which

means having no self-draining cockpit and no self-draining stowage

boxes. With the two floats and the sandwich platforms the boat

is already unsinkable, and the only way to get water into the

cockpit is by sailing in the rain.

Im also thinking about a deck

tent that includes the foredeck and the platforms. It would offer

full standing headroom in the cockpit and allow two persons to

sleep on the platforms (which are 1,90 m x 85 cm each). Together

with a cockpit table that would mean caravan comfort on a 16 foot

boat!

(click HERE

for Folding Tri study plans)

|