Containing

1. an account of a sail shaped like

a bear's paw

2. a method for sailing downwind with

a boomless sprit sail

3. a light daggerboard case and sprit

for camping

Here

is a sail which is really a kite. It sits on the top

of a short mast where it is free to rotate and twist.

It is controlled by a downhaul attached to the front

and by a continuous main sheet attached to the two sides

near the back. The boat in the photo is not really sailing.

It is just being blown sideways in front of the camera.

The breeze is coming from the left. The white office

building hiding in the trees opposite is the headquarters

of Canada's notorious tax bandit bureaucrats (Canada

Customs and Revenue Agency). I suspect they have someone

on the roof scanning the water for boats that don't

gibe with reported incomes. Here

is a sail which is really a kite. It sits on the top

of a short mast where it is free to rotate and twist.

It is controlled by a downhaul attached to the front

and by a continuous main sheet attached to the two sides

near the back. The boat in the photo is not really sailing.

It is just being blown sideways in front of the camera.

The breeze is coming from the left. The white office

building hiding in the trees opposite is the headquarters

of Canada's notorious tax bandit bureaucrats (Canada

Customs and Revenue Agency). I suspect they have someone

on the roof scanning the water for boats that don't

gibe with reported incomes.

Two

sails have been rigged on the boat at the same time

to show their relative size and location. The blue canvas

sail is a 5x4.5 boomless sprit sail with a mast sleeve.

The beige nylon sail is a 5x4.5 polynesian crab claw

sail which looks more like a bear's paw than a crab's

claw. We don't have any crabs in the woods of Ontario

where I imagined using the sail on camping trips. But

we do have bears. Both sails are cut from standard 5ft

wide fabric store cloth. The mast for the blue sail

is right at the bow. The mast for the beige sail is

at the front thwart and puts the front of the sail right

at the bow. Both of these sails are located so the boat

can be sailed with the existing daggerboard and no rudder.

Both are well balanced fore-and-aft. Two

sails have been rigged on the boat at the same time

to show their relative size and location. The blue canvas

sail is a 5x4.5 boomless sprit sail with a mast sleeve.

The beige nylon sail is a 5x4.5 polynesian crab claw

sail which looks more like a bear's paw than a crab's

claw. We don't have any crabs in the woods of Ontario

where I imagined using the sail on camping trips. But

we do have bears. Both sails are cut from standard 5ft

wide fabric store cloth. The mast for the blue sail

is right at the bow. The mast for the beige sail is

at the front thwart and puts the front of the sail right

at the bow. Both of these sails are located so the boat

can be sailed with the existing daggerboard and no rudder.

Both are well balanced fore-and-aft.

The

bearpaw sail is a nylon bag made to fit over two bent

fibreglass tent poles. The idea is to carry the sail

on a camping trip without having to carry a long mast

and sprit. And to use the tent poles to avoid carrying

extra weight. Since a sail and a tent are not needed

at the same time on a camping trip it should be operationally

feasible. The mast is just long enough to let the sail

be drawn in close hauled without hitting the side of

the boat. The sail was made last winter. As soon as

it was tried on the water it became abundantly clear

that if tent poles are flexible enough to bend in a

semicircle at the front of the sail then they will also

bend at the back of the sail. As soon as the wind filled

the sail it became baggy at the back and lost much of

its power. The solution so far was to cut one 1/4"

plywood batten for each side, put loop of wire in the

ends, and slip them over the tent poles where they are

not supposed to bend. A big improvement but not ideal.

In the photo there are bricks holding the flexible tent

poles in at the sides. The 8 ft 2x2 stud was put in

the photo to show the scale but it got cut out of the

photo at one end. Note the unfair kink in the curve

of one of the tent poles at the top right. That is the

repair described below. The

bearpaw sail is a nylon bag made to fit over two bent

fibreglass tent poles. The idea is to carry the sail

on a camping trip without having to carry a long mast

and sprit. And to use the tent poles to avoid carrying

extra weight. Since a sail and a tent are not needed

at the same time on a camping trip it should be operationally

feasible. The mast is just long enough to let the sail

be drawn in close hauled without hitting the side of

the boat. The sail was made last winter. As soon as

it was tried on the water it became abundantly clear

that if tent poles are flexible enough to bend in a

semicircle at the front of the sail then they will also

bend at the back of the sail. As soon as the wind filled

the sail it became baggy at the back and lost much of

its power. The solution so far was to cut one 1/4"

plywood batten for each side, put loop of wire in the

ends, and slip them over the tent poles where they are

not supposed to bend. A big improvement but not ideal.

In the photo there are bricks holding the flexible tent

poles in at the sides. The 8 ft 2x2 stud was put in

the photo to show the scale but it got cut out of the

photo at one end. Note the unfair kink in the curve

of one of the tent poles at the top right. That is the

repair described below.

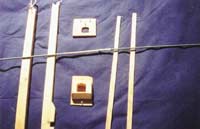

On

the left is the mast with its loop at the top for the

sail to twist and turn on. Two holes were drilled through

the mast so the loop would not drop down one side with

the weight of the sail. Not apparent in the photo is

a thin hole through the mast just under where the partners

go. A piece of stiff wire (a bicycle spoke) goes through

the mast to keep it from lifting out of the boat. The

sail is, after all, a kite and tries to leave the boat

vertically under some conditions. Next to the mast is

the, um, yard or boom or whatever its called. A loop

of string in a hole on each end ties it to the sail.

The end does not need to be notched as shown. The notch

is left over from another method I tried of attaching

the sail. Two blocks have been screwed on at the middle

to keep the loop on the mast from moving off centre.

Top centre in the photo is the mast "partners"

that I've been using while testing the sail. It screws

onto the thwart on the boat. This is the third "partners".

The other two were of thinner plywood. They broke when

the boat capsized. The mast step is the usual wooden

block with a hole in it. The hole is odd shaped because

the mast is a piece of stairwell handrail. A previous

mast step of lighter construction broke when the boat

capsized. On the right are the two plywood battens which

keep the back of the sail from bending. On

the left is the mast with its loop at the top for the

sail to twist and turn on. Two holes were drilled through

the mast so the loop would not drop down one side with

the weight of the sail. Not apparent in the photo is

a thin hole through the mast just under where the partners

go. A piece of stiff wire (a bicycle spoke) goes through

the mast to keep it from lifting out of the boat. The

sail is, after all, a kite and tries to leave the boat

vertically under some conditions. Next to the mast is

the, um, yard or boom or whatever its called. A loop

of string in a hole on each end ties it to the sail.

The end does not need to be notched as shown. The notch

is left over from another method I tried of attaching

the sail. Two blocks have been screwed on at the middle

to keep the loop on the mast from moving off centre.

Top centre in the photo is the mast "partners"

that I've been using while testing the sail. It screws

onto the thwart on the boat. This is the third "partners".

The other two were of thinner plywood. They broke when

the boat capsized. The mast step is the usual wooden

block with a hole in it. The hole is odd shaped because

the mast is a piece of stairwell handrail. A previous

mast step of lighter construction broke when the boat

capsized. On the right are the two plywood battens which

keep the back of the sail from bending.

Across the centre of

the photo is one of the fibreglass tent poles showing

a repair. The metal tubing at the end of one of the

sections split along a seam. It was repaired by winding

wire around the end and embedding it in epoxy adhesive.

The fibreglass on the adjoining section also split.

That was repaired by winding polyester twine around

and embedding it in epoxy adhesive. The repair is far

from perfect. I asked about tent poles on the rec.camping

newsgroup. There are better quality fibreglass tent

poles. On some expensive tents flexible aluminum poles

are used. To discourage more splits a bead of epoxy

adhesive was run along the seam of each metal tube on

the tent poles. There have been no more splits.

I'm

not sure this bearpaw sail is practical for camping

trips, but it sure is fun trying to learn how to sail

with a kite. In Polynesia the ocean winds are steady

and the downhaul at the front of the sail is set and

cleated off. On the small waters where I sail the wind

is never steady so the downhaul is wrapped once around

the mast and cleated temporarily in the teeth, under

a foot, or held in one hand. It takes two hands to work

the mainsheet, pulling in on one side and easing out

on the other. In the light winds where I dare use the

sail it seems to work best at about a 45 deg angle to

horizontal as in the photo. When the wind picks up the

boat heels but the sail does not twist off and spill

wind like a sail laced to the mast does. The bearpaw

sail just lifts one side and draws stronger than before

which accounts for the capsizing. I have not capsized

this boat with the blue sprit sail. I have been out

with the blue sail in winds so strong that I could not

paddle into the wind. Its quite amazing. I lie down

as low in the boat as possible and give it its head.

Such a small boat surging along in such strong winds.

The blue foam sponsons help, of course. I'm

not sure this bearpaw sail is practical for camping

trips, but it sure is fun trying to learn how to sail

with a kite. In Polynesia the ocean winds are steady

and the downhaul at the front of the sail is set and

cleated off. On the small waters where I sail the wind

is never steady so the downhaul is wrapped once around

the mast and cleated temporarily in the teeth, under

a foot, or held in one hand. It takes two hands to work

the mainsheet, pulling in on one side and easing out

on the other. In the light winds where I dare use the

sail it seems to work best at about a 45 deg angle to

horizontal as in the photo. When the wind picks up the

boat heels but the sail does not twist off and spill

wind like a sail laced to the mast does. The bearpaw

sail just lifts one side and draws stronger than before

which accounts for the capsizing. I have not capsized

this boat with the blue sprit sail. I have been out

with the blue sail in winds so strong that I could not

paddle into the wind. Its quite amazing. I lie down

as low in the boat as possible and give it its head.

Such a small boat surging along in such strong winds.

The blue foam sponsons help, of course.

But

the centre of effort on the bearpaw sail is high, the

rig is heavy, and its sailing characteristics too unfamiliar

and powerful to go out in any but the lightest winds.

Polynesian crab claw sails are estimated to be up to

40% more powerful on a beam reach than other kinds of

sails. I believe it. To reef a crab claw sail the sides

are pulled together making the sail loose and baggy.

I do not dare pull the tent pole sides together as the

poles might break. To reef the bear paw sail I pull

the pin, lift the mast up out of the step and partners,

and toss it overboard where it floats on the surface

until the wind calms down. Next season I plan to move

the bearpaw sail to a bigger boat, the Dogskiff, that

can cope with its power. I've already tried the sail

on the Dogskiff but the mast must be moved aft to balance

the sail fore-and-aft. If anyone is interested in trying

such a sail I'd recommend tying off any rudder amidships

to have both hands free to work the lines. I'd suggest

flexible plastic electrical conduit for the bent front

and broomsticks for the straight sides of the sail. But

the centre of effort on the bearpaw sail is high, the

rig is heavy, and its sailing characteristics too unfamiliar

and powerful to go out in any but the lightest winds.

Polynesian crab claw sails are estimated to be up to

40% more powerful on a beam reach than other kinds of

sails. I believe it. To reef a crab claw sail the sides

are pulled together making the sail loose and baggy.

I do not dare pull the tent pole sides together as the

poles might break. To reef the bear paw sail I pull

the pin, lift the mast up out of the step and partners,

and toss it overboard where it floats on the surface

until the wind calms down. Next season I plan to move

the bearpaw sail to a bigger boat, the Dogskiff, that

can cope with its power. I've already tried the sail

on the Dogskiff but the mast must be moved aft to balance

the sail fore-and-aft. If anyone is interested in trying

such a sail I'd recommend tying off any rudder amidships

to have both hands free to work the lines. I'd suggest

flexible plastic electrical conduit for the bent front

and broomsticks for the straight sides of the sail.

For more information

on crab claw sails look at schachtdesign.com.

The prototype for my sail is the John Rowland drawing

at the bottom of this

page . David Beede's experimental polytarp sail

based on the Rowland drawing can be seen at simplicityboats.

The boat used with the bearpaw sail is the Loonie which

appeared in Duckworks last year. A building plan and

description can be found on

this

website.

When

I first started sailing with the blue canvas sprit sail,

every time we got hit by a gust downwind the boat would

do a snap 90 deg turn to the side. Try as I might I

could not muscle the little boat back on course in the

gust. The best I could do was force the boat to go downwind

sideways. The phenominum is called broaching. It's quite

a problem with small sailboats. One day I discovered

I could control the boat downwind by letting the sail

fly out in front. One photo shows the boat sailing close

hauled toward an open dam. The other photo shows the

boat running down wind away from the dam. The sail has

done a 180. The sprit is out in front of the boat. The

bottom of the sail is pulled back into a pocket or bag.

It's much easier to control the sail that way than straight

out to the side in the normal downwind position. You

can only get a bag like that on a boomless sprit sail

with a rotating mast. I can avoid both broaching and

the dreaded dead man's roll with the sail in that position.

And I can avoid power gybing by reaching forward and

passing the whole mainsheet around the front of the

mast. I've used the technique on a larger boomless sprit

sail on my Dogskiff. On that boat I've come down river

on a windy day between high banks which compressed the

wind like a wind tunnel. It was an exciting controlled

sleigh ride with the sprit sail bagged out front like

a spinnaker. This downwind technique must have been

known previously to others but in all my reading I've

not come across it. When

I first started sailing with the blue canvas sprit sail,

every time we got hit by a gust downwind the boat would

do a snap 90 deg turn to the side. Try as I might I

could not muscle the little boat back on course in the

gust. The best I could do was force the boat to go downwind

sideways. The phenominum is called broaching. It's quite

a problem with small sailboats. One day I discovered

I could control the boat downwind by letting the sail

fly out in front. One photo shows the boat sailing close

hauled toward an open dam. The other photo shows the

boat running down wind away from the dam. The sail has

done a 180. The sprit is out in front of the boat. The

bottom of the sail is pulled back into a pocket or bag.

It's much easier to control the sail that way than straight

out to the side in the normal downwind position. You

can only get a bag like that on a boomless sprit sail

with a rotating mast. I can avoid both broaching and

the dreaded dead man's roll with the sail in that position.

And I can avoid power gybing by reaching forward and

passing the whole mainsheet around the front of the

mast. I've used the technique on a larger boomless sprit

sail on my Dogskiff. On that boat I've come down river

on a windy day between high banks which compressed the

wind like a wind tunnel. It was an exciting controlled

sleigh ride with the sprit sail bagged out front like

a spinnaker. This downwind technique must have been

known previously to others but in all my reading I've

not come across it.

Last

winter a small daggerboard case was made for the narrow

paddling and sailing Dogskiff. The Dogskiff and the

Loonie share the same daggerboard. I wanted the daggerboard

case to add as little weight as possible to the hull

which has to be picked up and carried over portages,

and lifted on and off the roof of a car. I was delighted

when it only added 2 pounds to the hull. Another goal

was to keep the daggerboard case out of the way when

paddling and when sleeping on the boat under its homemade

tent. The boat is paddled transom first for speed and

directional stability. That puts the daggerboard slot

on the high side of the heeled boat opposite a right

hand paddler and clear of the water. Water splashes

up the case into the boat when paddling in a chop. I

plan to make a plug for the top to block the water.

The case is braced low to the side where it doesn't

flex the thin plywood. Last

winter a small daggerboard case was made for the narrow

paddling and sailing Dogskiff. The Dogskiff and the

Loonie share the same daggerboard. I wanted the daggerboard

case to add as little weight as possible to the hull

which has to be picked up and carried over portages,

and lifted on and off the roof of a car. I was delighted

when it only added 2 pounds to the hull. Another goal

was to keep the daggerboard case out of the way when

paddling and when sleeping on the boat under its homemade

tent. The boat is paddled transom first for speed and

directional stability. That puts the daggerboard slot

on the high side of the heeled boat opposite a right

hand paddler and clear of the water. Water splashes

up the case into the boat when paddling in a chop. I

plan to make a plug for the top to block the water.

The case is braced low to the side where it doesn't

flex the thin plywood.

Its

the usual construction for a daggerboard case. Some

daggerboards go in at an angle like this one. Some are

installed straight up and down. These two photos are

included for anyone who has not made a daggerboard case

and would like to see how one goes together. This one

was made of cheap, light lauan underlayment plywood

which many boatbuilders would not use, and light red

cedar wood. Its

the usual construction for a daggerboard case. Some

daggerboards go in at an angle like this one. Some are

installed straight up and down. These two photos are

included for anyone who has not made a daggerboard case

and would like to see how one goes together. This one

was made of cheap, light lauan underlayment plywood

which many boatbuilders would not use, and light red

cedar wood.  The

interior of the case was given two thin coats of polyester

resin and two coats of polyurethane varnish for abrasion

and water protection. The edges of the plywood were

sealed with two coats of polyester. The rest of the

case got two coats of linseed oil which will be renewed

each spring along with the rest of the interior of the

boat. The glue used was PL Premium construction adhesive.

The glue lines at the slot in the hull were sealed with

two coats of epoxy adhesive. The

interior of the case was given two thin coats of polyester

resin and two coats of polyurethane varnish for abrasion

and water protection. The edges of the plywood were

sealed with two coats of polyester. The rest of the

case got two coats of linseed oil which will be renewed

each spring along with the rest of the interior of the

boat. The glue used was PL Premium construction adhesive.

The glue lines at the slot in the hull were sealed with

two coats of epoxy adhesive.

The

purpose of this sectional sprit was to replace a 12

ft pole sprit with something shorter and lighter for

camping. Three tubular steel handles from discarded

brooms did the trick. The 3 ft ruler in the photo shows

the scale. At the lower left pieces of dowel wrapped

in sheet aluminum cut from soft drink cans were glued

with epoxy into the ends of two tubes to provide something

for the open ends of the middle tube to fit over. The

open ends were reinforced by gluing collars on them

which do not show up in the photo, cut from the tube

and split open to fit. Foam rod insulation was shoved

inside so the sections would float if any fell overboard.

Barely visible in the upper right, the ends of the broom

handles had ready made holes for tying the mast and

sail to the sprit. The sprit was painted white, unfortunately

causing the photo to be overexposed. A couple of photos

taken during construction were lost when the film was

in a capsize of the Loonie while trying out the bearpaw

sail. The

purpose of this sectional sprit was to replace a 12

ft pole sprit with something shorter and lighter for

camping. Three tubular steel handles from discarded

brooms did the trick. The 3 ft ruler in the photo shows

the scale. At the lower left pieces of dowel wrapped

in sheet aluminum cut from soft drink cans were glued

with epoxy into the ends of two tubes to provide something

for the open ends of the middle tube to fit over. The

open ends were reinforced by gluing collars on them

which do not show up in the photo, cut from the tube

and split open to fit. Foam rod insulation was shoved

inside so the sections would float if any fell overboard.

Barely visible in the upper right, the ends of the broom

handles had ready made holes for tying the mast and

sail to the sprit. The sprit was painted white, unfortunately

causing the photo to be overexposed. A couple of photos

taken during construction were lost when the film was

in a capsize of the Loonie while trying out the bearpaw

sail.

It

was a cool and windy fall day on a crystal clear northern

lake when the new daggerboard and sectional sprit were

tested together. Both performed above expectation. A

canoeist discouraged by the high wind went home after

a short paddle. Before the photo was taken the boat

had been slipping through whitecaps and gliding over

streaming foam with ease. The daggerboard case is so

fortuitously placed that the boat can be steered by

raising and lowering the board. If the board is raised

3/4 way the boat rounds up into the wind and tacks. It

was a cool and windy fall day on a crystal clear northern

lake when the new daggerboard and sectional sprit were

tested together. Both performed above expectation. A

canoeist discouraged by the high wind went home after

a short paddle. Before the photo was taken the boat

had been slipping through whitecaps and gliding over

streaming foam with ease. The daggerboard case is so

fortuitously placed that the boat can be steered by

raising and lowering the board. If the board is raised

3/4 way the boat rounds up into the wind and tacks.

The photo shows a blue

sports bag used as a back rest when sailing from a reclining

position. The bag is stuffed with gear and clipped to

lines through holes just under the gunwales aft of the

daggerboard as seen in the photo. I made the mistake

of sailing in a strong wind without back support early

in the season, pulled a muscle, and could hardly walk

for two weeks.

The modified nylon canoe

and kayak sail from TF Jones "Boats To Go"

is in its fourth season. The double layer of fabric

store nylon is stretched and baggy and showing its age,

but still moves the boat along at a good clip. The hull

is in its third season. It is better now than when first

built. I think its finally the way I want for paddle

and sail camping. There is more information on the history

of the Dogskiff in files at www.ncf.ca/~ag384.

- END - |