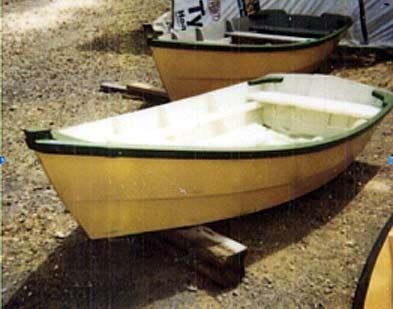

BOAT

BUILDING WITH A DIFFERENCE IX

(For Aspiring Amateurs)

by Barend Migchelsen

LOOKING BACK

When America was “discovered”,

there were only two native hull designs: the canoe and the kayak.

By themselves, marvels of the “art” of design, and

the “craft” of construction.

On the east coast, all the other

boat designs are the result of the know-how of European emigrants:

English, Scottish, French (St.-Pierre), Dutch, and German (Lunenburg).

According to the guru of

American Small Boat Building, the late John Gardner, dories were

developed from constant-flared, straight-planked double-enders

of which the sheers had a “natural” bend. See page

43 in The DORYBOOK.

The definition of a “natural”

bend is: “part of a circle arc,” or a “circle

segment.”

Originally the sheer line

of the double-ender was a circle segment. The “tombstone”

stern which made the double-ender a dory, came in later. Also

later came the varying flare, the straightening out of the sheers

aft, and fore which resulted in a steeper, nearly straight curve

in the bow, and a change from “biscuit” shape to “cod’s-head,

mackerel-tail” form.

Each design is a compromise.

The first compromise is

the ratio LOA/Beam. By making a hull wider, you will gain more

stability and loading space. You will loose streamlining which

slows the boat down.

Making the hull narrower

will result in less room; the hull becomes “tender”,

or less stable. It reduce the water resistance.

Boats were built long before

people learned writing, drawing, and math in schools. Ages of

experience taught the first, illiterate builders that for double-enders

the best compromise between Length Overall and Beam is LOA/Beam

= 4/1.

To put it in figures: measured

inside, a double-ender with a LOA of 16 feet should be 4 feet

wide at Beam. If you stick to this ratio, for small boats you

don’t have to make any other calculations.

When

the tombstone stern was brought in, the double-ender became a

dory. It shortened also the LOA to 15½ feet. That is were

the odd sizes come in. When

the tombstone stern was brought in, the double-ender became a

dory. It shortened also the LOA to 15½ feet. That is were

the odd sizes come in.

Another thing is that East

Coasters have the habit to either calling the length of a dory

by the length of the waterline in the USA, or by the length of

the bottom in Canada.

If called by the length

of the bottom (Lunenburg), the actual Overall length is 7 feet

for what is called a 5-foot Dory. Subsequently a 12-foot Dory

has an actual Length Overall of 15' 6".

Back

to flare. The first double-enders were constant flared. That flare

angle was, and still is, 33 degrees, 41 minutes, 24.24 seconds

(33º 41' 24.24"). Back

to flare. The first double-enders were constant flared. That flare

angle was, and still is, 33 degrees, 41 minutes, 24.24 seconds

(33º 41' 24.24").

It sounds crazy. But

it is NOT!

Look at the flare as the

hypotenuse of a right triangle. Make the ratio between the short,

opposite leg and the long, adjacent leg 2/3. You get this odd-looking

angle figure of 33 degrees, 41 minutes, 24.24 seconds.

LIKE THE 3, 4,

5 CARPENTER’S TRIANGLE, THE 2/3 RATIO ITSELF IS A MARVEL

OF SIMPLICITY!

This ratio is nothing new.

It is the “maximum” flare figure that is

found in many European designs, much older than the dories, like

the Dutch farmer’s punters (about 500 years). The punters

were the most basically designed simple double-enders: two wide,

thick side planks set on a bottom formed as a biscuit.

When you check the (official)

drawings of the most typical “Lovell” dory at Beam,

you will find that exact flare angle ratio. So is it in the Dory

model-kit from Wind and Waves, from Dartmouth, Nova Scotia,

marketed at Can$29.95.

A 16-foot. Double-ender

with dory flare, made with straight side planks, produces a rather

excessive bottom rocker.

Experience taught the fisherman,

and subsequently the builders, that this was not good for a sea-boat.

It produces too much seesawing. To reduce the rocker in the bottom,

an extra partial strake, a stealer, was put in fore and aft.

At least in Lunenburg, east

coast dories have a reduced rocker of only approximately three

inches between Beam and bow.

Next development: the flare

ratio produces a very strong curve in the bow stem.

By straightening out the

sheer line fore, the bowline became steeper, and the curve was

reduced. It made it easier to cut the stem from the tough, curved

root stumps of Hackmatack trees. The bevel of the stem became

less varying, more constant. It gave more buoyancy fore.

This is where the “cod’s

head” came into the design. It gives more room over the

bottom fore without changing the overall length of the hull, or

the curvature of the sheer lines.

The most difficult, time-consuming

part of double-ender construction is making the stems fore and

aft. First, because they were made of tough-to-work hackmatack

root stumps, second, the cutting of the correct form is not easy,

even if you have a good template. The reason is that the bevel

angle of the sides of the stem is not constant.

Replacing one of the two

stems, the stern stem with a triangular transom board, the “tombstone”,

saved a lot of time and effort. The double-ender became a dory.

The tombstone has the form of a V, which is very simple and quick

to make from the easier-to-work-with cedar wood.

By allowing the side panels to go free (straight) aft from the

last setup frame as the tangent to the sheer line circle segment,

the bevel of the sides of the V-transom became constant, another

time saving improvement.

Dories have no rudder. By

making a cutout for an oar in the top edge of the tombstone, it

became possible to steer and/or scull the boat.

It seems only a very small

improvement, but for the lonely fisherman it could mean the difference

between life and death. If he had lost or broken an oar, now he

could scull back to the schooner, or, in case of inland fishing,

get back to the shore instead of drifting out into the ocean with

an outgoing current.

Replacing the stern stem

with a tombstone, and making the sheer line straight after the

last setup frame, resulted in a slightly longer, narrower bottom

aft: the “mackerel tail” of the “cod’s

head, mackerel tail” shape of the bottom. This effect is

greatly enhanced by increasing the height of the side panels and

bow fore. The chines no longer run parallel to the sheer

but their lines are converging towards Beam.

Dories are open boats. With

the loose cross benches removed, they can be stacked eight to

twelve boats high aboard a schooner. Before WW2, the schooner/mother-ships

sailed to the Grand Banks. The purpose of the dories was not

to be sailed, or rowed, but to provide a safe fishing platform

to which the (cod) lines could be anchored.

The side panels were made

very wide, 26 to 30 inches for a 15½ ft. hull. This served

dual purposes: The deep hulls could hold a big load of fish. The

crew could lean safely against the side without having to be afraid

of falling overboard while working the lines. Falling overboard

was disastrous because most fishermen could not swim, besides

having little chance in the often rough, chilly waves with their

heavy clothing of two or three sets of longjohns under their heavy

flannel shirts and corduroy pants, rain gear, and high rubber

boots. They fished within hailing distance of the mother ship

that often was invisible in the frequent, heavy fogs.

The windage factor of the

high sides was not important. Once the fishing lines were out,

the boats were stationary. As mentioned before, their only purpose

was to provide a safe fishing platform. The beautiful, eye-catching

shape of the dory was not important, except for riding the waves

extremely well in their anchored-to-the-lines positions in, most-of-the-times,

rough swells. They needed no skeg, no keel. Some had a small mast

with a spritsail aboard. With that set up, and no keel, or even

a skeg, they drift quite a bit to lee. It did not matter, the

distances to the schooner were short, and there was plenty of

room in the ocean.

They also (mistakenly) believed

that a shot of rum helped protect them against the relentless-penetrating,

cold and damp climate, which could be seen in the discoloring

of their faces: bluenoses.

There used to be quite a

few rumrunners that had their home bases in one of the many, difficult-to-patrol

inlets of the Nova-Scotia east coast. The schooner captains bought

the rum directly at sea from these runners.

Now you understand why the

queen of the schooner fleet carried that name. Most East-Coasters

have a good sense for humor.

Odyssey

If you have gotten the impression

that I was trying to show you how to build a Dory, then I have

given you the wrong idea.

What I am writing about

is that how the Odyssey of 20 years slow, and often frustrating

research if the lines of hard-chined, constant-flared hulls were

based on simple mathematics that were easy to understand for aspiring

amateurs, and get them started into building, succeeded. It resulted

in a system that would allow any person who had completed

the math of grade eight of secondary school, and is interested,

to design, loft and construct his own hull from double-ender,

dory, skiff, punt, dinghy to pram, with any amount of flare.

To do this, no higher

mathematics, the trial-by-error guesswork of conical development,

or expensive software of Computer Aided Design (CAD) is needed!

But, it does require an

open mind, especially from the experienced builders that

have never done, or seen it done that way. Just refresh what

you learned about the Theorem of Pythagoras.

Once an aspiring amateur

has succeeded with his first boat, in 90 percent of the time,

he is hooked. Nothing will stop him, or her anymore.

So, now you can never

say that you were not warned before you start giving in to that

contagious urge of building your own boat.

Over that 20-year period,

I have measured and tried to analyze the lines of every hard-chined

hull I could lay my hands on, discussed, and often debated that

issue.

Since those hulls were mainly

dories and dory wrecks, it explains how they were so often mentioned

until now. From this moment on, I will be talking only about double-enders

and how you can develop other hull shapes from this basic boat.

Lunenburg

I have married children,

grandchildren, and a sister-in-law living near Halifax, N.S. During

our twice-yearly visits, I started to checkout boat builders in

that area, and tried to ask questions.

Kim

Smith is the proprietor of the Dory Shop at the very end of the

Lunenburg waterside. He is a builder who really knows what he

is doing, and has thought a lot about design. Kim

Smith is the proprietor of the Dory Shop at the very end of the

Lunenburg waterside. He is a builder who really knows what he

is doing, and has thought a lot about design.

One day I asked him: “Kim,

how do you design your dories?’

The answer was: “I

never did. I have a bottom and a stem template, and a set of frames

for every one of the 11 sizes that are built here, hanging on

the walls. All I do is to set them up and plank them.”

Next questions: “Where

do these frames come from? Who made them?”

Kim: “I don’t

know. The shop has been here since the early 1900s. After the

shop had been closed for a few years, I was asked to open it up

again. The frames were hanging on the wall. Since they are tried,

and proven to produce beautiful dories, all I do is set them up

and start planking.”

It suddenly dawned on me,

why I never got the right answers. Many of the old timers had

learned how to set them up and do the planking, but had never

bothered to ask further questions. In their heydays, especially

before WW2, they made good living planking the set-up frames,

and for nearly all of them the rest was of no interest.

They could never have done

that without set-up frames.

Eureka

In 1990, after rereading

John Gardner’s DORYBOOK that phrase on page 43

started to hitch in my (rusty) brain box: Sheer line, “natural”

bend. But after 15 years, I had not come one step further.

In the summer of 1991, I

had an accident. In the dark, I fell in an uncovered basement

hole. I landed on a concrete floor, seven feet lower, with one

broken, and one cracked pelvis bone.

In the hospital bed beside

me was a cabinetmaker with a locked shoulder. He was reading a

woodcraft magazine; I read the last issued WoodenBoat Magazine.

When we were finished, we

switched literature. And there it was, the mathematics of a circle

segment on a chord with the utterly simple calculation of the

relationship of the (maximum) height of the circle arc to the

length of the chord, and the radius of the circle.

I had just turned 70 in

1991, and all what I had learned in grade 8 of the secondary school

56 years earlier, and that had been forgotten, came back to me

in that week in the hospital bed.

John Gardner’s remark

about the connection between the sheer line of a double-ender,

and a circle arc segment had indeed pointed me in the right direction.

The solutions jumped at me right from that magazine page.

I have reproduced that drawing.

If you are like me, a long time behind this stuff, that drawing

will help to refresh your (rusty) memories

If you are like me, a long time behind this stuff, that drawing

will help to refresh your (rusty) memories

Above all, keep this drawing in mind for the first five written

articles of this series. You will see how this diagram relates,

and is the key to a set of drawing plans for a constant-flared,

hard-chined double-enders.

In the here-reproduced drawing,

(click to enlarge) note that:

R = the radius of the circle arc

h = the (maximum) height of this segment on the chord

R - h = the distance between the chord and the center point.

In the right angled triangle, the long, adjacent leg = R - h.

The short, opposite leg = ½ length of the chord

The hypotenuse of the triangle = the radius R.

Apply the theorem of Pythagoras:

Worked out the answer is:

I am a Dutch emigrant who came

in 1959 to Canada. My only mathematical knowledge is what I learned

in secondary school between 1933 and 1939. That is a long time

ago.

After three years of learning

to adapt to our new homeland, as most beginning immigrants, I

earned not enough to live, but just enough not to starve. I became

a life insurance agent working on commission. That is a love-hate

affair: Every Monday morning you start from square one. Even when

you have sold a policy, you still don’t know if the client

will pass a medical exam. You bite your nails for another week

to ten days. If the medical examiner turns him, or her down, you

have lost it.

To work off my frustrations, in

1975, I took up boat building as a hobby. I built a 16-foot Frisian

scow with leeboards (See page 229- Boatbuilding by Chapelle

for a 22-ft. illustration). In the Netherlands they make them

with oak planks, heavy workboats. Mine was built from ¼"

ply. Quite a difference.

Notwithstanding that she was a

lot lighter, the boat sailed terrifically and to my surprise was

very stable and had a perfect balance. Call it “beginners

luck.”

After having built two, or three

more hard-chined hulls, I began to suspect that hard-chined designs

were based on a few, simple, straightforward mathematical theorems.

How could I find that out? Where to start?

On trips to these cities, I went

to all the public libraries from Toronto, Ottawa, Montreal, and

Halifax. Researched in the boating section # 623 all what was

available on the subject “Building”. In the mean time,

I also tried to keep up with the magazine publications in North

America, England, and Holland. I bought some of the books (if

I could afford them).

All that literature gives many

details, but never a simple, mathematical answer.

But why, with so many plans around,

pursue this at all?

Here are the reasons:

If my suspicions were correct,

finding the solutions meant that, at least, I had mastered the

theory. Then, I only had to bring up the practical part to par.

After all, I had no training, or schooling in that direction.

I did not have the time, or the money to get one. Like many of

you who read Duckworks Magazine, I was only an aspiring amateur

dreamer of building boats.

But there were other considerations

too: For an amateur, the ideal place for building a boat is under

a carport. But the wintry climate of Canada and many states of

the USA makes that impossible for at least six month of the year,

sometimes longer, depending on where you live. It forces the amateur

builder into hibernation for that part of the year. With mathematics

you can prefab the smaller parts precisely in a small place indoors,

a kind of constructing your own building kit, and assemble the

hull outside as soon as the weather allows it. That way you get

a head start on the season. What a trade school would take two

years to teach you in theory, could be done by reading at home

in a couple of weeks and by making a to-scale model from inexpensive

cardboard on the kitchen table. The building of the model turned

out slightly more difficult than the real thing because of the

smaller tolerances and the inferior (paper) material. It gives

perfect “hands-on” training that costs next to nothing.

It shows you all the difficulties that turn up in building the

full-sized model, and then some.

Before WW2, having a secondary

school leaving certificate was not for everybody. That changed

drastically after WW2. Today everybody must have that piece of

paper. It is only the first rung on the career ladder.

That means that today everybody who is at least 15-years old,

knows the basic math of the theorem of Pythagoras and the (basic)

definitions of the trigonometric ratios of sine, cosine, and tangent.

If, at his time, John Gardner,

who had a college education, had worked that out practically,

he would have had very few people he could tell it to. As was

the custom in those years, most boat builders got only an elementary

school education. Because of the economic conditions, quite a

few of them never completed their elementary schooling. Today

everybody has learned the simple math in secondary school.

The hard-chined dory is developed

from a constant-flared double-ender by replacing the stern stem

with a triangular transom board. It only changes the design in

so far that the LOA became ½ to ¾ foot shorter.

A hard-chined Dory-Skiff is developed

from the double-ender by lopping ¼ of the LOA aft, and

plugging the hole with a transom board. That makes the ration

LOA/Beam change from 4/1 to 3/1. There is no change to

the shape of the chine and sheer lines, or in the shape of the

bow. Beam lies then at 2/3 of LOA.

A Punt is a Dory-Skiff of which

1 to1½ foot of the bow is cut off. The hole is plugged

with a (bow) board.

In other words: The mathematics

not only show you how to build one boat, but the whole range of

hard-chine hulls from double-enders to prams, without having a

buy a new set of plans for each model.

It has become a system.

Here comes another little gem.

The flare (angle) of hard-chined,

small-boat hulls can vary between zero degrees (no flare) to maximum

flare = dory flare =33 degrees, 41 minutes, 24 seconds = 2/3 ratio.

For a 16-foot double-ender with

dory flare that means a sheer line half-Breath at Beam of 24",

and a Profile height of 16". Please take note of these figures.

You can find and check them with the tables in BBwaD

III of this series.

For convenience, most hard-chined

small boat designs have a flare (angle) that falls between 6 degrees

and 30 degrees.

By starting to play with the flare

ratio figures, an amateur who has digested the mathematics and

understands them, can design his own hard-chined, small-boat hull

between 1-ft. LOA to 30-ft. LOA, with a flare between 0 degrees

to maximum (dory) flare, over the whole range of hull types: from

double-ender to prams as is shown in the two tables of BBwaD III.

For example, the ratio 10/24 gives a flare angle of 22.62 degrees

= 22 degrees, 37 minutes, 12 seconds. Another difficult figure,

but an easy template setting: A right triangle with a

long leg of 12", and a short leg of 5".

It is no longer a question of

buying a plan and attaching batten A to frame B. Any “planker”

can do that. It has become a complete understanding of design,

lofting, and construction, the what, the why, and the how of a

series of hard-chined, small-boat hulls.

You won’t need a PC

with expensive software. No higher mathematics. No trial-by-error

conical development.

All that you need, and what today

every interested amateur has, although he, or she, may have to

refresh that because it was a long time ago that you learned it,

is what you were taught in grade 8 of secondary school: the theorem

of Pythagoras, and the (basic) definitions of the trigonometrically

ratios Sine, Cosine, and Tangent that are found on a secondary-school

pocket calculator. You can always ask any teenager of 15-years

and older to help you. They will be delighted to bring you up

to date (again).

What I have written here might

upset a lot of professionals who make a living by selling the

expensive software, the plans, and books that will tell you that

you can build a canoe in 6 (six) hours, or a skiff in 8 (eight)

hours. I am sorry to say that there is not, or that there ever

will be such a thing as an “instant” boat short from

buying one.

If you are an aspiring amateur

builder and dream of building your own boat, be prepared that

the construction of the hull is only 1/3 (one-third) of the job.

Finishing, and painting are the other two 1/3 parts.

Sheers and chines, Barend.

If you have missed any of the preceding articles

of the Boat Building with a Difference look up the name “migchelsen”

on the web. You can retrieve the whole series from there.

|