BOATBUILDING WITH A DIFFERENCE

VIII

(For Aspiring Amateurs)

By Barend

Migchelsen

(Click

here for Barend's book page)

A Laser-type Car Topper

In Montreal, the yearly Boat Show

is held early in the year.

Notwithstanding knowing better,

every year I still go there with the (very vague) hope of seeing

something with more character than the usual assortment of plastic

toys and aluminum cans. And always, without fail, there is some

fiberglass contraption that is hailed as “the boat of the

year”, a “breakthrough”, or whatever nice superlative

they can think of.

Usually, there is not much new

to it, and you never hear or see more of it after the show.

Over all these years, I have seen

only three exceptions that survived their 15-minutes-of-being-famous.

They are here to stay. The three boats are: the Optimist Pram

which has proven itself as an excellent sail-trainer, the Hobie

Cat 16 Catamaran with the asymmetric hull sides for sophistic

sailers, and last but not least, the Lasers.

I am not sure if the total number

of Lasers all around the world already passed one million. But

if not, they should be close to it. That is more than any other

type of boat ever sold.

What makes this 13-foot 10-inch

wet-sailer so attractive is it’s simplicity -- achieved

without giving up any of the finishing touches like the boom vang

and the Cunningham tackle on a high ratio mainsail that fits with

a sleeve on a round mast. No halyard with pulleys, sail track,

or mast groove is necessary.

The hull itself is very flat,

not more than twelve inches, without a skeg. The bottom is round

with very little rocker. The boat is fast, can turn on a dime,

and planes easily. An exciting toy for teenagers to play tic-tac-toe.

The mast consists of two parts. That, and a longitudinal-slightly-concave,

flat, wide deck without any extruding edges make car topping easy.

There is only one “but”

with this one-design, state-of-the-art sailing machine: In Canada,

the price is close to Can$7000. ($6995) With the 15.56 percent

sales tax added that becomes more than Can$8000 (year 2002 catalogue

price)! Now, if for that amount you could sail all year around

for 24 hours, 7 days a week, you could probably get your monies’

worth of fun out of it in a couple of years.

But in a country where the leisure

boating season for wet-sailers lasts only two months, that would

take a very long time.

Although I don’t consider

myself poor, I think that I am not the only one who is not willing

to pay that amount for just a leisure pastime.

That left me with only one choice:

If it is possible to modify this set of plans of THE SYSTEM shown

in figure 1 into a set of plans of a hull with Laser qualities

as shown in figure 2, then it would be possible to build an experimental

boat for less than Can$400. That amounts to only 5 percent of

the other cost outlay. After milling that over for a couple of

days, it became a very attractive idea.

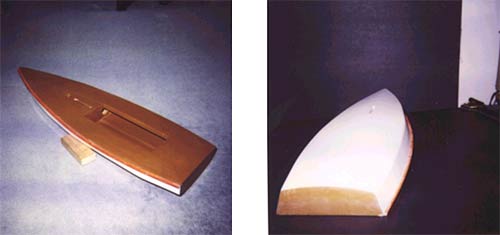

Figure 1

Figure 2

Well, the modifications in Profile

and Half-Breadth drawings are easy. But the compound curves of

the bottom in Body view are difficult to copy for plywood. The

best that can be done is illustrated in figure 3.

Figure 3

In the drawing are the following

changes

1. The side panels are

cut off level with the deck.

2. The width of the side panels at Beam is reduced to 9".

3. Across, the bottom is rounded. The bottom camber at Beam

is 2.875" (2 7/8)".

4. The camber is constant over the whole length of the bottom.

5. Longitudinally, the bottom centerline is a straight line

to prevent compounded curves in the plywood bottom panel.

6. The vertical transom is 10.25" at the

center of its crown. The frames become ¼"

higher per station toward fore. At station #2 the height of

the frame is 12.75". At dead center at

station BAC, the distance between deck and bottom is

12.9".

7. The decks beside the cockpit are widened to 12".

8. A dagger board replaces the centerboard.

9. The deck fore is made longer to behind the dagger board box.

10. The deck aft is 24" long.

11. There are no coamings around the cockpit, just a finishing

edge.

Hull Construction

The method of construction is different. Build the hull from the

deck up.

Deck

1. With the good side under,

put a 4'x5' board of 1/8"

Philippine mahogany aft against a 4'x7' board

to make the 12' deck.

2. Temporary, secure the panels in this position longitudinally

with two 1" slats 32"

apart with ¼" screws with a round

head.

3. Draw the longitudinal centerline on the panels, and the ten

station lines at 12" intervals.

4. Plot the deck contour line with the measurements shown in

figure 3.

5. Where possible, at a distance of ½",

draw a second contour line outside of the first line.

6. Cut off the excess outside of the second line.

7. From a piece of scrap wood, make a right triangle with legs

12" and 5". Place

the short leg on the table of the table saw. Set the blade at

22.62º against the hypotenuse of the template.

8. Rib a 13' batten of 1"x2"

finished lumber of knotless pine, or spruce at the angle of

22.62º. Check that the two battens are

perfectly equal. If not, take the thinnest batten. Adjust the

guide against it. Run the other slat through for a second time.

9. Soak the battens for 24 hours in water in a 4"

ID plastic rain pipe, 14' long, and

closed off with a cap on one end.

10. With the beveled side on the outside, clamp the wet battens

along the inside of the first deck contour line. Work slowly

and precisely. See figure 4. At station #8, keep the battens

1/8" inside of the plotted sheer line

to allow for the bevel of the sheer line deck edge.

11. At the bow, cut the first clamped batten flush with the

opposite sheer line. Miter the second batten against it in a

tight fit. Do not cut the overlapping ends at the stern yet.

12. If the battens are too stiff for the bending onto the deck,

let them dry first. Make small partial kerfs 3", or 4"

apart. Soak them again, and clamp them onto the deck.

13. After they have dried overnight, glue them onto the deck

with plastic resin glue. See figure 4, and the photograph.

Figure 4 Inwales

glued onto the deck

14. With a utility knife remove

the ½" excess outside the glued-on

inwales. Hold the knife against the beveled battens. To prevent

tearing into the grain, start at Beam, work towards the bow

and the stern. Make sure to cut at bevel angle without cutting

into the inwales. Make the first cuts very lightly.

15. Cut the hole for the mast, the slot for the dagger board,

and the cockpit opening.

16. Cut off the overlap of the inwales at the stern 1/8"

fore of the end of the deck. See the photograph.

Cross Frames

1. Make 1/8"-wide

cuts into the inwales fore of and against the station lines

#2, #4, and #6. Be careful not to cut into the deck. See the

photograph.

2. Make the same cuts in the inwales aft of and against the

station lines #8 and #10.

The cross frames are made from

1/8" Philippine mahogany. Start with frame

#8.

1. Cut a rectangular panel of

14"x50". Draw a vertical middle line

on the panel.

2. Place the panel into the inwale cuts at station #8. Line

up the vertical middle line of the panel with the centerline

on the deck.

3. Mark the exact width of the panel at the sheer lines of the

deck.

4. Remove the panel. Draw the camber line of frame #8 on the

panel as shown in figure 5. Cut out the panel.

5. Cut all the other panels in the same way by first marking

their exact width while they are positioned in the inwale cuts

on the deck. Take the bend of their crowns from the first

cut panel #8. See figure 5

Take the sizes of the bevel angles

of the sides of each frame directly from the deck when the width

is measured.

Note that the crown line of each

frame is lined up with the crown line of frame #8. Their exact

heights are measured on the vertical middle line from the crown

line down. That way the curve of the crown line is the same for

all the frames.

Figure 5 Half-Body

view of the cross frames.

Longitudinal Frame Fore

1. Make a 1/8"-wide

cut in the inwales over the centerline at the bow.

2. Cut the longitudinal bow frame to the measurement of figure

6. Note that the highest point of the bottom (12.9")

is at station BAC.

3. Place the frame between the tip of the bow (station #0) and

frame #2.

4. Glue a piece of 1"x1" on the deck

between the inwales and the frame at #2 station.

5. Glue a second piece of 1"x1" on

the opposite vertical side of the bow frame.

6. Temporary, attach the bow frame to the 1"x1"

on the deck with round headed, ¼"

screws.

7. Place the cross frame #2 in the slots on the deck. Attach

frame #2 in the same way to the vertical 1"x1"

of the bow frame.

If the frames are lined up perfectly,

both frames stand absolutely perpendicular on the deck, and perpendicular

to each other. The sides of frame #2 are flush with the curve

of the deck at the inwales.

Figure 6 Longitudinal

bow frame

Longitudinal Frame Aft

The longitudinal frame aft

is placed between the bulkhead at station #10 and the transom

board at station #12. The measurements are taken directly from

the setup. Cut out the middle of the frame to reduce weight. Check

for a perfectly perpendicularity to the bulkhead, the transom

and the deck. Attach the frame to the deck, the bulkhead, and

the transom with pieces of 1"x1" just

as the bow frame fore with temporary screws.

Dagger Board Box

Install the 18"-long

dagger board box fore of the bulkhead at station #6. The dagger

board box trunk aft is attached fore against that bulkhead. Use

1"x1" pieces of lumber to attack the

box to the deck. The method of construction of the of the dagger

board box is the same as the method of the building of the centerboard

box of the skiff. The width of both boxes is the same also. The

difference is that the bottom line of the skiff is curved. The

bottom line of the car-topper is straight.

Mast Box

The mast box is set aft of the

X-frame at station #4. The four walls of the box are made of 1"x1"

plank. Inside the box is 3" wide. Close

up the mast box with a cover of the same wood to protect the bottom.

The photograph shows two frames, one, fore and one aft of the

box. This extra frame aft of the mast box can be omitted. Instead,

make the sides of the dagger board box long enough to anchor them

onto the mast box.

The longitudinal frame between

the X-frames at station #2 and station #4 seen in the photograph

can also be left out. In that case, glue a piece of 1"x2"

over the centerline onto the deck instead. The holes in the frames

#2, and #4 can be made a lot bigger to reduce weight further,

and allow for better air circulation. Make the holes in bulkheads

at station #6, and #10 round. On the water, these holes are closed

off airtight with conical plastic cups to create two flotation

chambers. A longitudinal frame attached to the carlins and the

bottom on each side of the cockpit between the bulkheads fore

and aft will add two additional flotation chambers, making the

hull practically unsinkable. Make round holes in these panels

that can be closed off airtight also. When the boat is stored

on land, the cups are removed for ventilation.

Bow

Gussets

The bow

gussets are ripped from 1"x1"

lumber. They are glued on each side fore the longitudinal bow

frame.

1. Miter

two pieces of 1"x1" at the same angle

as the bow angle of the longitudinal bow frame. See figure 6

2. Place the lumber against the frame on top of the inwale on

the deck.

3. Mark the inwale line on the lumber.

4. Rip the lumber at this bevel angle.

5. Repeat this for the other side.

Chines

The first bevel of the chines

is ripped from a 1"x2" in the same

way as the sheers. The angle of the second bevel is equal to the

angle between the side of X-frame #8 (Beam) and the bottom curve.

It is taken from this frame.

Chine Notches

Making the notches for

the chine battens is a precise job. Remove the temporary placed

X-frames and bulkheads from the deck. The chine batten must fit

perfectly flush with the sides, and the bottom line of the frames.

The easiest way is to undercut the notches slightly and then file

them to the exact size.

Cut off a small piece from the

chine batten. Use it to check the correct size of the notches.

Placing the Chines

1. Glue all the prefabricated

parts onto the deck. Double-check that they are all perfectly

perpendicular to the deck, and to each other. Be finicky about

this!

2. Secure the dagger board and the mast foot box extra with

stainless steel screws to their trunks and the frames.

3. Line the transom frame #12 fore, and the bulkhead #10 aft

with a piece of 1"x1" along the bottom

curve on each side of the longitudinal frame.

4. Do the same with bulkhead #6 fore on each side of the dagger

board box, and with the X-frame #4 aft besides the mast foot

box.

5. Place a perfectly straight 1"x2"

batten on its narrow side over the frames on the centerline.

Check is the frames heights are correct. Correct small mistakes.

6. When you are satisfied with the lineup of the setup, place

the chine battens in the notches. Glue them against the frames

and their linings.

7. Check for any humps, and/or hollows in the chine line. Correct

small discrepancies.

8. Make a 1/8"-wide, and 2"-long

vertical saw cut into the Beam frame #8 on each side beside

and against the chine battens on the cockpit side. These starter

cuts make it easy later to remove the middle part of the frame

that blocks the cockpit.

Carlins

Attach the 1"x1" carlins onto

the longitudinal sides of the cockpit between the bulkheads #6

and #10.

Optional Extra Flotation

Chambers

Install the vertical walls of

the extra chambers against the carlins and the bulkhead.

The bottom edge is flush with the bottom curve of the bulkheads

to which they are attached with vertical pieces of 1"x1".

Line the bottom side of the panel inside also with 1"x1".

Sand the 1"x1"s flush with the bottom curvature.

For ventilation, cut two round

holes in each panel as shown in the photograph in bulkhead #10.

Side Panels

Each side panel is made

up from two boards: a 16"x 96" (8')

board aft and a 21"x60" (5')

board fore. The board aft is lined up with the transom. That places

the 4" wide joint of the board between stations

#5 and #4.

Installation of the Side

Panels

1. Cut a 4"x 16"

butt strip of 1/8" Lauan.

2. Cut 4"-wide, 1/8"-deep notches

into the chines and the inwales in the middle between station

#4 and #5. Make sure not to cut into the deck.

3. Place the butt strips into the notches. Cut them flush with

the chines at the bottom side. Make sure that they blend completely

and perfectly fair with the chine and the deck lines. Draw the

vertical middle line on the strips.

4. Attach temporarily 4.5' of 1"x1"

under the deck at station #8 (Beam). The 1"x1"

protrudes 3" on each side of the deck.

5. Place the aft panel on the protruding part of the 1"x1".

Place a C-clamp on the lumber against the panel to hold the

board firmly against the setup, but can still be moved.

6. Attach the panels against the inwales and the chines with

temporary screws at the stations from aft toward fore.

7. Mark the location of the vertical middle line of the joint

strip on the side panel. Cut off the excess of the side panel

with a utility knife. It is not necessary to take off the panel

from the setup. Just hold a piece of scrap Lauan under it to

protect the strip while you make the cut.

8. Draw a pencil line along the chines and the deck on the side

panel board. Cut off the excess above the chine and under the

deck. It can be done on the setup with a snap-off utility knife

by extending the blade as far as possible. Work slowly, away

from the grain. Put hardly any pressure on the first couple

of strokes. The best tools for this kind of a job are a veneer

saw, or a Japanese flush-cutting saw. A second way is to take

off the panel and cut along the lines with a jigsaw set at the

flare angle. Take your time. Aim for a perfectly fair

line. Correct small discrepancies with a file, or sandpaper.

9. For attaching the side panel board fore, you need a helper

to hold the board against the panel aft at the joint between

stations #4 and #5 while you align the height of the panel,

and place the temporary screws at the joint. Again place the

next screws by working from aft to fore.

10. Draw the lines and cut off the excess above the chine line,

under the deck, and fore of the stem.

11. Once you are satisfied with perfectly cut and placed panels,

tape the top edges of the chines with masking tape to prevent

spilled glue spots on these battens.

12. Glue the panels with plastic resin to the chines, the inwales,

the butt strip and the X-frames. Use roundhead screws at regular

interval where it is not possible to use clamps. To prevent

dents, use cardboard washers between the screw heads and the

wood.

13. When the glue has dried, remove the screws; overfill the

holes with wood filler. When dry, remove the excess with fine

sandpaper. Remove the masking tape from the chines.

Bottom

The bottom is made up

from two boards. The first board is 8' long.

One edge is lined up with the heel of the stem. The other edge

comes to nearly 5" aft of station #9. The

second panel is jointed to the first panel with a 4"-wide

butt strip also.

Installation of the Bottom

Panels

1. Place the 4'x8'

panel on top of the setup. Align the front edge with the heel

of the bow stem. Hold the panel in place with a temporary roundhead

screw.

Make sure that the longitudinal middle line of the board is

lined up with the centerline of the hull.

2. Mark the place of the panel edge aft on the chines. Remove

the panel and make 4"-wide, 1/8"-deep

notches in the chines, 2" on each side

of the mark. Make sure not to cut into the side panels.

3. Replace the bottom panel. Over the middle line, attach the

board with the temporary screws with the cardboard washers to

the frames. Work from fore toward aft.

4. Attach the bottom panel to the chines with the temporary

screws. Do not attached one side completely to the chines first

and then the other side, but work both sides from fore to aft.

5. Draw the bottom contour line on the underside of the panel.

Cut off the excess in the same way as was described for the

side panels.

6. Cut a 4"-wide strip of 1/8"

Lauan that fits exactly into the cut notches when it is given

the bend of the bottom curve.

7. Draw a longitudinal middle line over this joint strip. Put

resin glue on the side fore of the line. Clamp the strip under

the bottom panel. Let the glue dry. The joint line is approximately

4.75" aft of station #9 (station line

#9 + 4.75").

8. Place a 3'-long board aft against the bottom

panel fore. Attach and glue it in the same way to the frames,

the chines and the transom. Work from fore toward aft. To hold

the panel tightly to the joint strip, use the round-headed temporary

screws with the cardboard washers while the glue dries. Cut

off the excess.

Staggering

Note that the deck joints

are in the narrow parts of the deck. The joints in the side panels

and the bottom are staggered away from the deck joints

as far as the material permits.

Transom Reinforcement

Cover the transom with

an additional panel of 1/8" Lauan that overlaps

all the seams with the deck, the side panels, and the bottom by

1". Cut off the excess.

Sealing the Seams and the

Joints

Seal all the seams and

the joints with Buckram tape and resin glue (urea formaldehyde).

Finishing

Glue in the 1/8"x1"

bottom slats

Painting the Hull

Paint the hull with the colours

of your choice, but make sure that they are highly visible. The

secret of a good paint job is not in the use of expensive marine

paints, but in careful preparation.

To prevent eye glare, use a

flat paint on the topsides.

Use non-skid porch paint on the bottom inside the cockpit.

Rudder

The rudder for the car-topper

is a kick-up rudder.

Gunwales

Rip the gunwales

at a flare angle from a 13' - 1"x2"

batten. Plain varnish them, or paint them in a contrasting, bright

colour. Screw them to the hull after the hull is painted

Trial Rigging

Before you spend a lot of money

on rigging, make a mast from a 12'-2"-ID

PVC pipe with a 12' - 2"x2" slat stuck

inside the pipe. Make a lugsail, from a 10'x12'

polyethylene tarpaulin. With this trial rig you will find out

how the boat performs

Total costs

Without skimping on the hardware

and the fittings you will stay within your budget of Can$400.

For this bargain, I got three times as much fun than from buying

a real Laser: First, the fun of building the boat, second, the

pleasure of sailing the boat, and thirdly, the fun of “laughing-all-the-way-to-the-bank”

by saving myself 95% of the costs. Not a bad deal IMHO.

Barend

Migchelsen

(Click

here to go to Barend's book page)

|