I actually got the hull of my

Puffin 28 turned over on July 6th, but I've just been having too much

fun to update the

website.

Well, it wasn't all fun--my best friend and sailing buddy out here died

earlier on that day, and that has added some symbolic triumph to the

event, but I'll get to that part of the story in good time.The

roll-over went exactly as planned, and took me less than two hours,

working alone. There was additional time spent in preparation of course,

and afterwards to get the boat onto the cradle and leveled, but the actual

'event' was amazingly fast, uneventful and simple, but profoundly

emotional as well.

|

Model of Puffin 28 |

To recap the process, I had floated a few ideas on the roll-over

since the building began. I considered the usual methods, like slings and

tires and so forth; or building some sort of semi-circular framework, or

thirty friends and lots of beer (I don't have 30 friends!). I really

hadn't settled on anything, just figgered with my previous experience as a

rigger and millwright, it was no big problem, and I'd let events lead me

to the method in good time. About a year ago, I stumbled on a website of a

guy building a similar sized, but slightly smaller boat. He rolled his

boat by attaching two brackets to the boat, one at each end, that served

as pivots. The upside-down hull was lifted slightly, the structure

underneath removed (strongback, bracing, etc) and the boat simply pivoted

like a chicken on a bar-b-que rotisserie, then set on a trailer. The more

I thought about this as the project approached the roll-over point, the

more I liked it. I did some careful measurements, and it looked like the

boat could be pivoted right in place, with about one inch of room to spare

under the roof.

I made the final decision to go with this method, and started

hunting up junk and steel around the place to build my pivots. I did no

formal engineering, just relied on seat-of-the-pants and past experience,

and I let the materials I found dictate the design. In essence, both

pivots are simply pipes that extend a short distance horizontally, one at

each end of the boat. The rest of it is the mounting and bracing needed to

attach the pivots to the hull, and keep them rigid enough to support the

boat thru 180 degrees of free rotation. I added up all the materials that

had gone into the hull at that point, and estimated a weight of about 2300

pounds--relatively light--and now I had an idea how strong the fixtures

needed to be. Just some welding and burning and head scratching--about

three day's worth, and I'd have my pivots.

|

bow pivot |

(A few years ago I built a large hoist similar to a Travel Lift

without wheels, and lifted my 8500 pound Columbia sailboat a few feet in

the air from poppets and blocking on the ground, and lowered it onto a

flatbed trailer, then welded supports in place, and transported the boat

myself 400 miles into Mexico. Rolling this Puffin was not a big concern as

far as size or weight. I even still have the hoist if I needed it.)

For the bow pivot (right), I used a piece of 4" channel iron about

16" long. This fit nicely over the stem. A piece of 1-1/4" steel pipe

about a foot long was welded to the channel, so that it would project

level and horizontally. The pipe was braced to the channel, and also two

arms ran to the hull, one each side about two feet back from the bow. The

channel iron was bolted to the stem with two 8" wood lags, and the braces

mounted with 3/8" bolts drilled right thru the hull, with wooden pads

outside and steel plates inside to spread the load.

|

stern pivot |

For the stern, I welded up a similar fixture, except the pipe was

welded to a piece of 1/4" steel plate about a foot square, and this in

turn was welded to two angle irons about three feet long, forming

something like the letter 'H' layed on its side. Some additional bracing

of the pipe to the plate completed it. This fixture was thru-bolted to the

transom with six 3/8" bolts, and plywood pads and large flat washers on

the inside of the transom.

The height of the pivots, or the rotational axis of the boat, was

based on the half-width of the boat. I simply measured the widest beam,

about 9'-2" as it sits now, and placed the pivots half that plus an inch

above the ground. The idea was that the boat would not need to actually be

lifted, just the weight taken on the pivots, and the boat would clear the

ground and (by lucky coincidence) the roof as it rotated.

|

staging |

Next was the problem of how to actually lift the boat. I have four

3-ton chainfalls (hoists), plus a good assortment of jacks and chains and

slings and so forth, but how to hang the lifting gear was the question.

The roof over the boat house won't take that kind of weight, it's just a

light duty wood frame and metal roof. I did consider shoring up the

rafters at each end and hanging the hoists from them, but looked for a

better solution.

For the stern, I set up my staging, or scaffolding, the type made of

pipe frames commonly seen on construction sites (except I had made this

set myself years ago; I'm just that kind of guy). I hung one of the

chainfalls from one end of the staging, set up as close to the transom as

possible.

I have to detour a bit here--in the weeks prior to this, I had

welded up my cradle, discussed earlier on a previous page. I had dragged

this cradle (estimated weight of 500 pounds) with my pickup from one side

of my shop to the other, and then used chains and come-alongs to drag it

as close to the stern of the boat as possible, leaving me enough room for

my staging. The idea was, that once the boat was flipped over, I would

support it somehow, remove the staging that was in the way, and drag the

cradle under the boat. Then the boat could be lowered into the cradle. The

point of this little tale is that the cradle was next to the staging

(right), and I chained the staging down to the cradle, to keep it from

lifting, as all the weight of the boat (well, one end) would be pulling

down on one end of the staging, tending to lift the other end. The chain

is barely visible by the lowest step of the step ladder. The rudder turns

so easily that the wind has weathercocked it!

cradle

For the bow of the boat, I did some pondering, and decided the

simplest way was the best: I took a 4x4 post, and mounted a large eyebolt

at one end. This was actually a piece of powerline hardware (more

collected junk), an eyebolt welded to a heavy 'U' shaped plate, that fit

the post perfectly. I stood the post upright, and simply clamped it to a

braced 2x4 and the fascia rafter of my boat shed roof, to secure the top

(see picture above of bow pivot). For the bottom, the post and 2x4 were

lashed to a length of steel bar driven into the ground like a stake. All

it had to do was be kept in place, the pull would be almost directly

straight down. Another chainfall was hung from this eye.

All the above was part of the preparatory work in the week before

the actual roll-over. I had also been removing un-necessary structure from

under the boat for several weeks, and was down to a section of strongback

about 12 feet long, supporting two bulkheads in the boat, so most of the

space under the boat was open and clear--that in itself was exciting,

after crawling over all that stuff for more than a year. Now I could walk

around under there openly, and I cleaned up a year's worth of sawdust and

shavings and scraps, and raked my ground carpet clean.

|

I lifted the boat just enough to put tension on all the lifting

gear, then I built two sets of 'sawhorses', one at each end under the

boat. These were just four piles of stacked 8x16 cement blocks, with a 4x4

spanning two piles and running under the boat at each end. At this point I

removed all remaining strongback structure and bracing from under the

boat, except some cross bracing on the boat itself to support the shape.

This stage took several days. I let the boat down onto the two

'sawhorses', to make sure they would support the weight, and left the boat

there for a day. Then I lifted the boat just clear of the sawhorses, and

let it hang from the pivots for a day or so, to make sure everything was

happy. It was weird to be able to push on this huge hull with a coupla

fingers, and have it gently

sway. Now I was confident the fixtures and rigging would hold, and I let

the boat back down onto the sawhorses, keeping a tiny bit of tension on

the pivots as well. I was just waiting until the time was right. A few

people had expressed great interest in being around for the roll-over, so

I tried to plan things for the event. I didn't actually expect to need

physical help, like that friend we all know, "Manuel Labor", but some

company would be nice, one friend in particular, Ken.

It was during this period that my old friend Ken started to fail.

Ken had lung cancer about four or five years ago, and they removed an

entire lung and a portion of the other. He never came back 100% from that

insult, but at 67 he managed to go about his business, including sailing.

He took things easy and got out of breath easily, but we had just done the

two-day International Regatta down in Mexico in May on his Santana 22, and

he partied right along with all the rest of us. He seemed about as good as

he'd ever been.

He had previously promised to be there for the roll-over, and tho'

he said he couldn't help physically, he wouldn't miss it for the world. He

never actually laid a hand on Puffin as far as the building went, but he

was often hanging around, and offering advice, the loan of a tool, a

special piece of wood from his hoard, or just some comic relief. But in

the week or two leading up to the roll-over, he'd been complaining about

being tired, and not being able to catch his breath. He was staying inside

and close to home, and on oxygen.

Now, Ken had always been a good friend, a fellow woodworker and

cabinet maker, pack rat, boat nut, and we'd spent many hours and days

together over about twenty years--sailing, cruising, racing, working on

boats, drinking beer, telling lies, sharing the moaning chairs at each

other's shop, helping each other with our various projects and schemes.

Ken was always the best source of what I came to call 'lateral

thinking'--if there was some sort of problem or puzzle in some project or

another, Ken was great for coming up with some totally off-the-wall idea

or solution. I think when people are thinking real hard on a problem, they

tend to get into a sort of tunnel vision while considering solutions. Ken

could come up with some way of looking at things that was totally

unforseen--I called it lateral thinking, as his thought process would just

be going down a parallel tunnel--a different track-- to my own, but we'd

both end up at the same place. We had hashed over the various roll-over

schemes, and in the end, he liked this 'rotisserie' plan the best too.

Ken (picture

right) is the guy that gave me the steel basis for the cradle, as well

as two gallons ($250 worth!) of the VC Performance bottom paint, and even

gave me the HVLP sprayer to apply it! He said he wouldn't be painting any

more boat bottoms. In retrospect, I believe he was sending out clues of

his impending doom. Ken (picture

right) is the guy that gave me the steel basis for the cradle, as well

as two gallons ($250 worth!) of the VC Performance bottom paint, and even

gave me the HVLP sprayer to apply it! He said he wouldn't be painting any

more boat bottoms. In retrospect, I believe he was sending out clues of

his impending doom.

I saw him at home the morning of July 4th, and he was feeling

poorly, on oxygen and weak, but up and alert and his spirits were good.

His wife was worried, and thought he was declining, and wanted him to go

in the hospital--he refused, and said if he went in, he wasn't coming out

again. I brought a wheel chair to his house, and got him into it, and made

him promise me that if he got too bad, he'd go into the hospital. He said

he was just going to take it easy for the weekend, and he'd see his doctor

on Monday after the long holiday weekend. I left for the day to go to our

sailing club's picnic and get in some Laser sailing. When I got home

around five PM, I got a call from Ken's wife, they had rushed him to the

hospital in an ambulance. I went right in of course, and stayed by his

side until after ten PM. He was having great difficulty breathing, but was

still alert, and made me give a full report of the day's sailing and

stuff. We brought his wife home, and I planned to see him the next day.

I went about my boat building the next day, figuring to give Ken's

family time to visit and all, and I'd go in later that afternoon. I got a

call from Ken's wife late in the day, and she said Ken was 'going', and

I'd better get in there if I wanted to see him. Well, his wife is a bit of

a worry wart, and prone to anxiety attacks and so forth, so I figgered she

was just over reacting. I got to the hospital around 6 PM, and Ken was not

doing well at all, altho oddly he actually looked better, color-wise and

so forth. He was on morphine heavily, and nodding in and out, but he gave

a weak wave and smile when he saw me, and once or twice started awake

while we hung around the bedside, and asked "what'd I miss?" thru the

oxygen mask. I stayed by his side until about ten, along with another

friend. We had made his wife go get something to eat, with the rest of the

family. I fully expected to see him the next day. I was awoken at 6:30

Saturday morning, July 6th, and told he had died at 2:30 AM, just a few

hours after I'd left his side. I went directly up to his house, and of

course it was the usual madness, with friends and relatives coming and

going. We stayed all morning, but finally I had to leave.

We got home around noon, and my wife went in to town to do some

shopping. I was in a state of shock, and just sort of trying to absorb

this whole thing. I've never had a close friend die like this before. I've

seen people blown up or shot in Vietnam, but this was different. I

wandered around the shop and boat a while, just sort of lost. The boat was

sitting there ready to roll, and all of a sudden I got some sort of

inspiration. It was like an outside force put me on autopilot, and I

simply proceeded to roll that boat, without giving it much thought. I knew

it was ready, I knew it would work, and I said "why not?"

First I took the weight entirely on the chainfalls. I removed the

4x4 crosspieces and a row of blocks from each pile on one side of the

boat. I got mid-ship, and barely had to lift, and the boat gently tipped

down onto the blocks a few inches. I added a row to the other side, and

continued on, removing blocks from one side and adding them to the other,

so that the boat could not fall more than several inches if something

failed. Oh yes, I also set up a camcorder for time-lapse recording of the

event. I hope to post that here at some point, but it might be a

while--it's two hours of rolling condensed to about three minutes.

When the boat got to about 45 degrees, the block piles lost their

usefulness (visible at lower right in the picture below), as the

widest part of the beam was approaching the ground. I also noted the boat

was top heavy, or rather bottom heavy, as it was the keel and deadwood at

the top that were trying to spin the boat over. I rigged a rope around a

bulkhead (lower center), and attached that to a come-along chained

to one of the concrete piers for the roof posts. Now I simply eased the

come-along, and the boat continued to rotate in a slow and controlled

manner.

There was a bit of consternation when the boat got to 90 degrees, or

right on its side. I had laid some old carpet on the ground before even

building the strongback, so that was under the boat. Well, it seems my

'one inch clearance' had shrunk, and the sheer was scraping up the carpet

(rubbing on the ground) and also pushing up on the 2x6 rafters of the roof

as it rotated. Fortunately the sheer was not cross-braced in the contact

area, and if you look closely, you can see the flat spot in the

unsupported sheer between two bulkheads. I kept checking things, and

easing the boat over a few clicks of the come-along at a time, and since

it looked like it would make it, I pressed on--what else to do?

Once

the boat went beyond 90 degrees, it cleared the roof and ground, and it

was just a matter of winching it over until it was upright (or actually

letting gravity do its job, and simply controlling the process). I set it

down on the carpeted ground, with some blocks to keep it upright. At this

point I sat down, and actually realized that after almost two years of

building, the boat was safely right-side up. I was happy of course, but

also strangely numb--I said out loud in a clear voice "This one's for you

Ken!", and I burst into tears like a baby. I had my first real experience

of grief over the loss of my friend, and in a way, rolling the boat was

some sort of closure (I hate that word). I beg your indulgence for

the length of this tale, but it's certainly more than just a boat

rolling--at least to me--it's a sort of eulogy to a lost friend. And the

telling is some sort of relief as well. Once

the boat went beyond 90 degrees, it cleared the roof and ground, and it

was just a matter of winching it over until it was upright (or actually

letting gravity do its job, and simply controlling the process). I set it

down on the carpeted ground, with some blocks to keep it upright. At this

point I sat down, and actually realized that after almost two years of

building, the boat was safely right-side up. I was happy of course, but

also strangely numb--I said out loud in a clear voice "This one's for you

Ken!", and I burst into tears like a baby. I had my first real experience

of grief over the loss of my friend, and in a way, rolling the boat was

some sort of closure (I hate that word). I beg your indulgence for

the length of this tale, but it's certainly more than just a boat

rolling--at least to me--it's a sort of eulogy to a lost friend. And the

telling is some sort of relief as well.

My wife got home a short while later, and wandered out to Boat

Land--she was of course very surprised to see the boat right-side up, as

she'd only been gone about two hours, and it was upside down when she

left. She looked at it silently for a few minutes (I was still sitting

there, just having got done crying), then she said "you did it alone?"

Without thinking I answered "no, Ken was watching over my shoulder", and

burst into tears again. She hugged my shoulder and quietly walked away.

I no longer feel Ken's presence while I'm going about the business

of building, I'm sure he's moved on over his new horizon. But I'm also

sure on that morning, he paused at the start of his new voyage, and had

one last look over his shoulder, and he approved.

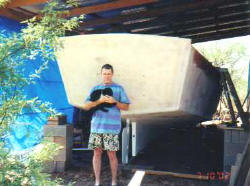

The

rest is an anticlimax, but should be told for enquiring minds. The next

day, I lifted the boat clear of the ground with the hoists and pivots, and

blocked it up...wooden blocks under the keel up front, and cement blocks

midship at the chines to stabilize it. I set up my 4x4 sawhorse on the

cement block piles again at the stern, to allow clearance for the cradle (the

blocks are visible at right. The builder's scowl is a parody of the cat's

expression, not a happy poser). The

rest is an anticlimax, but should be told for enquiring minds. The next

day, I lifted the boat clear of the ground with the hoists and pivots, and

blocked it up...wooden blocks under the keel up front, and cement blocks

midship at the chines to stabilize it. I set up my 4x4 sawhorse on the

cement block piles again at the stern, to allow clearance for the cradle (the

blocks are visible at right. The builder's scowl is a parody of the cat's

expression, not a happy poser).

The rest was just two days of dragging

the cradle under with a come-along (about one inch per stroke!) and chains

and so forth, and then lowering the boat into the cradle. Boat and cradle

were leveled accurately to make the interior work easier--not that there's

much level on a boat! |