|

1. Building Report

2. Sailing Report

Part I - Building

Basic

Concept Basic

Concept

The conception of the P5 is a light car-toppable proa for 1 to 2 sailors.

Both hulls are multichine designed for plywood/epoxy (stitch&glue)

building. The total weight should be 70-75 kg. The basic idea of the boat

is borrowed from Gary Dierkings strip planked

TARAWA.

Cutting Plans

The main hull has three parts: lee plank, luff plank up and luff plank

down. Every plank could made from mirrored halfs from 4mm plywood. Next

step is to glue a stringer (20x20mm) along the upper edge of the lee plank

(may be a second one into the middle) and of the upper luff plank for

fitting the decks later. Annother stringer should fixed at the below edge

of the upper luff plank. For more stablity use a keel batten (20x20 mm) as

backbone. Then the traditionary holes through the below edges of the lee

plank, keel batten and below luff plank.

Please

Note: All cutting plans and instructions are only proposals!

Building Pictures

Hull

Cut out planks with bulkheads

Main hull set into the support???. It's useful to build the support very

strong,

because the multi chine hull is unstable before gluing.

First the put the lee plank into the support, then the keel and the lower

luff plank. Next, stitch all together with copper wire. If all is

perfectly arranged glue it together with epoxy putty/glue. After the glue

has dried strengthen the keel section and the connection of the luff

planks with stripes of 200 gr fiberglass.

If the hull is stable, you can insert the cockpit floor and the beam

fittings. Pay attention to the paddle fittings. They should be match the

length/diameter of the paddle you use.

See details

Finally, fit the small decks and the wood poles for the webbing between

the beam fittings. Now all woodwork has finished and you can start sanding

the surface ...

The ama is built just like the main hull (aka). It's simpler because the

hull is symmetrical and it straightens itself after putting the bulkheads

in.

Ama ready for sanding and coating. Here you can clearly see the

arrangement of the poles between the beam fittings.

See details

For the first time both hulls are fitted with the

surf mast beams and with the 'test' sail made of polytarp.

Rig

The rig functions like a seesaw. By changing the bow after shunting

you pull down the yard with the sail to the new bow.

A good example is this rig at the

homepage of

Gary Dierking or in the Gibbons-Special at

multihull.de. This

Gibbons/Dierking rig has a simpler handling in opposite to the Crab Claw

sail. Also you should do easier maneuvers at the overcrowded lakes here

(Remark: This I thought before I tried it in reality. See 'sailing

experiences' below).

Fittings and running lines 1

Fittings and running lines 2

Sail

The Gibbons/Dierking rig has the advantage (like the Crab Claw) of needing

no shaped camber, so you can cut it yourself. I used a white standard

polytarp like you can get here in homeworker shops, double glued tape like

you use for carpet and to protect the overlapping parts, a special repair

adhesive tape.

Cut of the sail out of a minimal

tarp

Cut of the sail measurement (for first test)

Detail Views

Drawing - Hull Arrangement

Drawing - Beam fittings, Webbing

Drawing - Construction - Paddle fittings

Drawing - Yard connection

(now out of date, because no bamboo was used.

Used windsurfer masts are cheaper in Germany)

Disclaimer:

The plans of the P5 are free for building a boat for private use.

Commercial replication is not allowed. For rightness of all plans and

advices are no guaranty is given. Most parts in this descripton have only

a character of proposal and must be verified by the builder himself. Be

creative and courageously - and you can sail a P5 like me!

Part II -

Sailing

The Difference between Theory and Reality

The boat was finished to the extent that we did not know what else

could be done. From here, only experience would show us what was

missing: and this is exactly what happened.

Before the sailing story, some hints for building:

- Use 1-2 stringers for every hull side, otherwise the 4 mm plywood

makes visible cambers between the frames. The sleight additional weight

more will be justified by a better view and naturally, more stability.

- The windsurfer masts we used for beams an mast were not stable

enough. They will not break, but they are too limber for this

application. The whole structure of the boat would be too flexible,

which would have a bad influence on the rig and sail shape. A stiffener

of carbon roving makes it somewhat better, but for a future boat I would

use alloy pipes with a diameter of 50 mm and 3 mm thickness.

At last we were ready for launching. Transporting on top of the car

is absolutely easy. The beams rest on the side to side braces of the car

top carrier. In ten minutes the boat was ready to go on the car's

roof....

....and in a half hour, the boat was assembled and ready for sail.

The First Trip

It was a beautiful day, except that the wind was gusting to force 5.

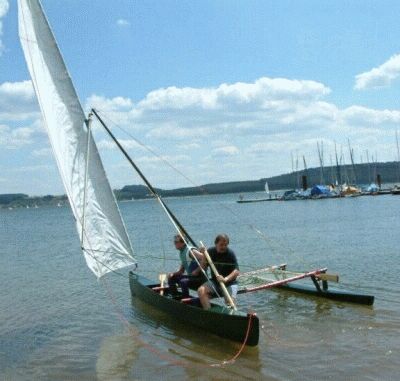

Nevertheless, this was the day! As soon as we assembled the boat, we

were on the water - a little prematurely - but we would finally sail.

(The first contact with its element. Here you see

the large leeward bend of the mast made among others by the curve of the

beams)

For us, however, fate had prepared something else. Because of the

tendency of the boat to luff, we made a big curve directly into the

foot bridges of the nearby marina. We stayed ashore until all the lines

were sorted. Fearlessly we pointed the bow toward the middle of the

lake, and ran, close hauled, into the 'open sea'. In fact pretty

successfully, as we sailed very fast, although the two of us were 2/3 of

the total displacement.

Steering, by moving our bodies along our sitting plank to change the

center of displacement, was very hard because of the gusty wind and the

boat's tendency to luff. The steering paddle seems to have no effect. The

result was that we sometimes got a gust from the 'wrong' side and the rig

came down to the wrong side too. But because it was held by rubber ropes,

nothing was damaged. The wind had, in the meantime, reached permanent

force 4 and we had no chance to set up the rig again. The paddling home I

don't need to describe ... we we used the time to talk about the 'Why'.

(The yard is bend to much astern. But in principle

the 50 $ sail looks good)

The Experiences And The Redesign

Basically, it was a positive experience. The boat floats almost

exactly at the theoretical CWL and carries two sailors who weigh about 150

kg (with a boat weight of nearly 75 kg). The asymmetric multichine hull

allows it to sail close hauled with acceptable leeway. The hulls/beam

connection with a simple webbing proved strong enough. Also the polytarp

sail was effective enough to give a good speed.

The following figures show something about the

'accidental research'

The figure above shows how the curve of the beams

and the sitting plank, where the mast stands, cause the mast to bend.

Additionally, stretching of the shroud exacerbated this effect.

Moving the CE by shortening the sail and

controlling the clew at the boom should optimize the sail shape.

Problem after the mast extension. The Schot angle

becomes smaller and the sail is more strongly distorted.

Additional

trim possibilities

Following changes were made before the next test sail:

- Stiffening the beams and the mast via carbon rovings

- Stiffening the sitting plank

- Lengthening the mast by 50 cm to bring the CE nearer to the bow

by arranging the yard more vertically

- Clew control at the boom

- Doubling of the rubber ropes to make the rig stiffer

- Shortening all lines to their necessary minimum for simpler

handling and to prevent catching oneself ;-)

Second Test

It was a beautiful summer day at the Brombach reservoir for the second

sailing test. The wind offered a 2-3 force breeze - great conditions!

After an hour of sailing we came back to our starting point. In that time

we had an eventfull trip. We tested the steering by moving the center of

gravity and controlling the sail trim. It functioned well. Moving to the

bow causes the boat to fall off, and moving astern means heading up. But

all must be done alertly and with a lot of feeling. The boat accelerates

rapidly - you must immediate close in the sail - and in the same time move

back with your body(s). The P5 is no boat for 'coffee sailors' (which in

German means 'cushy'), you are continually occupied. If you are sailing

with two aboard, permanent cooperation is needed:

Go to front, go back, pull here, etc.' ,

especially during shunting maneuver.

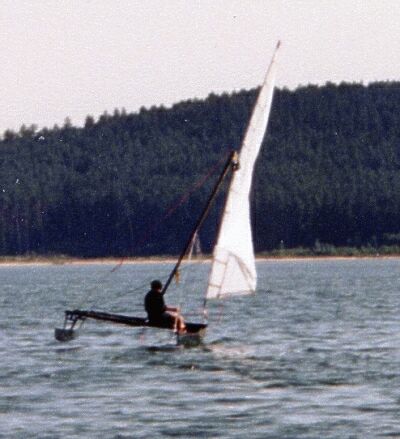

After the first test run I risked a single-handed trip. Alone, you

are much more tranquil because you quickly get the right feeling for the

boat and move automatically in the right direction. Also the speed

increases naturally with less weight aboard and so I could sail the first

meters with a flying ama.

Of course, this Bavarian lake is not the original home of a proa.

Constant turning and gusty winds are not useful conditions for sailing

such a boat. As quickly as it accelerates, it stops - and if in the

meantime the wind turns - you get it from the wrong side. The only potion

is to turn the boat with you paddle. BTW, as an Atlantic proa the P5 runs

surprisingly fast ;-).

At last, a word about the steering paddle. On a close reach you

don't need it, it hinders more than it helps. By moving the center of

gravity you can steer until you are on a beam reach. Downwind, you must

use the paddle.

Here you can clearly see that the lower part of

the sail has too much 'belly'.

Summary:

The P5 is a basically well-tried boat. It's a fun machine for

sailors who need an alternative to 'boring' beach catamarans. With a

better sail shape and maybe better sail cloth, I believe the P5 should

sail as fast as a comparable beach catamaran like a Hobie 14. And if not,

I promise you will sail it with at least twice the joy.

Next year we will change the rig to a Crab Claw Sail to compare the

rig types. We will inform you.

Othmar Karschulin/Phil Young

www.multihull.de |