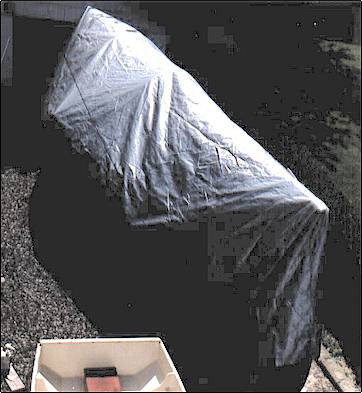

"Conestoga

Cover"

30 Degrees; rain & sleet; gray and overcast.

No great problem with my sailboat wrapped up in my back driveway. There

is about a 20 degree higher temperature under the Silver-gray plastic tarp;

even in weak sunlight. The wind fluttering the fore and aft portions of the

cover will both ventilate {to prevent mildew} and act as a Ďself sheddingí

action for snow.

It also gives me a boat workshop.

MAKE SURE the boat is SECURED to the trailer {or yard stands} and that

the TRAILER IS SECURE on JACK STANDS or HEAVY DUTY SUPPORTS.

Your typical micro- or mini-cruiser has a bow pulpit. {If not, this is a

wise investment to think about installing.}. The "trailerables"

have some sort of mast crutch that fits the rudder gudgeons. If you donít

have one there are the handymanís staples of 2x4's or PVC pipe readily

available. Pad the top of the bow pulpit; I use a split section of HEAVY

RUBBER GARDEN HOSE.

Suspend the mast across the protected pulpit forward and the mast crutch

aft; adjust the mast position so that only 2 or 3 feet projects behind the

transom. Disconnect any shrouds if necessary. If your trailer tongue sticks

out beyond your bow by 4 to 5 feet it can be protected by the cover and a is

a securing point as well. Make a support for the middle of the mast;

mine is a simple piece of 2 x 4 held in the tabernacle. This will prevent

"bowing". I secure the mast ends with inexpensive rubber straps.

Cheaper then ĎBungee Cordí for winter use.

Everybody either has worked with "plastic pipe" or has seen the

stuff in the local "hardware emporium". Itís usually indicated

as "Schedule 40" or 60 or 80, etc. depending on itís intended

use. This, because of CODE, is printed along the length of pipe itself.

"Plastic" pipe by itís very nature is a thermoplastic

material. That is it softens with heat, and printed on the pipe is the key

... " not for use above 140F". A little applied logic about safety

margins, wall thickness, volumes, and curves, and I had it.

At sea level water boils at 212F, PERIOD. No matter how long it boils it

wonít get above that temperature. There was my constant. The pipe was

HEAVY gauge PVC water pipe, NOT the translucent plastic or gray drain pipe.

I wanted; several "hoops" from the bow pulpit to the aft mast

gallows, looped over the supported mast. With padded blocks of

wood for feet, resting against cleats or toerail, they would act as

"flying buttresses" and take the strain of the cover, NOT the

mast.

To get the proper "curve" I measured gunnel-to-gunnel at the

points of intended support. I then calculated the VOLUME per INCH (inside

diameter) of the pipe. I used Ĺ inch for pulpit and gallows, 1 inch for the

rest. A 2"x4"x 8 feet long ( my West Wight Potter,

"QUAHOG" has a 7ft max beam), a ladder and some shock cord was my

"forming jig". Depending if you have help or not, you may need to

have some pegs and a drill.

Secure one end of the pipe to the 2x near one end. (Drill a

DEEP hole, use a THICK peg, secure the pipe AGAINST the peg with shock cord)

Wrap it well with the shock cord. This will be the "base point"

for all bends. Measuring from there mark where the other end,

(beam-to-beam), will be. Now youíre going to need some muscle and CARE.

BEND the free end up to which ever mark is desired, and SECURE it with the

shock cord. THERE IS A LOT OF STRESS HERE, SO BE CAREFUL. Place the 2x over

the ladder, or some other place which will allow access to the OPEN ENDS of

the pipe and the curve to hang down. Measure the CURVED AREA; tangent around

to tangent, as if it were half a circle. MULTIPLY that times the VOLUME per

INCH for how much BOILING water to use. DONíT FILL the

pipe, it will form a CIRCLE, you may lose your attachment points and be

scalded. For a SMOOTH curve, use a funnel and pour HALF

the calculated quantity of water into EACH END of the pipe. [If you

do this when itís cold the curve develops almost magically; itís fun to

watch it equilibrate itself ] After the curve has "settled" spray

it with cold water, then lay the whole thing down and flush it with cold

water.

It really takes longer to describe than to do. Really no waste; 10 ft

sections of pipe are standard, can be joined for longer lengths, and just

about last forever. The "jig" is any 2x4 and can then be used for

whatever else you want, and everybody has lengths of "bungee

cord".

Pad the top "side" of the mast. Old sheets, blankets, towels,

or sails . . . anything that will prevent chafe or puncture. Pad the ends

too . . . I padded and used plastic buckets.

Now comes the reason for all the padding.

A 19ft x 25ft "Ultra Heavy Duty, PLASTIC COATED, guaranteed for 3

years" silver-gray tarp only cost $45.00 - - - BUT you CAN

PUNCTURE IT. Get a hank of polyester tie-down line, use the grommet points

and GENTLY PULL the tarp over the "ridgepole"

created by the mast. Wrap the tarp around the boat {and trailer tongue, if

desired} and tie it down snugly but not "bowstring tight".

The fact that you are above the ground, and the ends of a rectangle are

wrapped around, allows air circulation. Now, even if you donít go aboard

until spring, you wonít have mildew growing over everything. With a

transom mounted boarding ladder, or a short step ladder and a little advance

thinking on your wrapping technique, itís an easy matter to get in and out

of the cockpit.. The amount of headroom you have depends on your mast crutch

arrangements.

![]()