Building

a Tortoise and a Daydream

by Warren Kyprie KF4call@aol.com

| I had been thinking about building a boat for a long time.

Sometimes I could actually see and feel myself out on this beautiful bright-finished

mahogany ketch with the whole family. On the other hand, I knew my free time and skills

were limited. Also, I had heard and believed that building and sailing were very

different, and that sailors often did not like boatbuilding. I didn't know if I would

enjoy building enough to persist until the boat was done. Despite the large size of my

dream, I eventually decided to build Tortoise, a 6 ft. 7 in. Phil Bolger design. |

| The small size of Tortoise didn't appear to fit

with my daydream. With a capacity of only one adult and a small child, I wouldn't be

taking out the whole family as I had visualized. Being "square" and with

external chines, it would not be described as a thing of classic beauty, |

|

| like the bright finished mahogany ketch of that same daydream..

So clearly the decision to build this boat did not fulfill the original dream of sailing

with the family in a classic boat. |

| With such a big, graceful daydream, why such a small plain

boat? I built Tortoise to answer two other questions that did not have to do with

appearance or capacity. The first was to find out if my limited building skills were

sufficient. The second question was about my stick-to-it ability. Would I get sidetracked

by something with a more immediate payoff, like going sailing? So the Tortoise project was

a "test" of my skills and the persistence. I chose to write this article because

I think other not yet first-time boatbuilders may have the same questions. Those other

articles on classic boat building can sure make the process seem intimidating. |

| I had never successfully built anything from wood.

There was a cigarette box I attempted in high school shop class. However, by the time I

managed to get the top piece square and approved by the shop teacher, it was the size of a

match box, not a cigarette box. The only other wood project was, as an adult, an attempted

bookcase. That project was actually very useful. Not because I ever finished it, but

because it helped my bride to have more modest expectations of the kinds of building

chores she could expect of me. I just couldn't seem to get the knack of working with wood. |

|

What about other boats besides the Tortoise? I looked at the 9

ft. "Rusty" design by George Strayer, a traditional dinghy. It was clearly the

classic look but beyond my abilities, even though it came with patterns. I bought the

plans for a Tracy O'Brien |

| designed stitch and glue 10 ft sailboat, "Meghan". It

was beautiful and had sweet lines, but the preliminary work seemed to go on and on, not

because it was so complex, but because I had to teach myself to do every little

preparatory operation. Not all was lost though, and from Tracy's detailed instructions I

learned to scarf really well. |

| I discovered Tortoise later. It's "square" shape

eliminated or reduced many technical problems and concerns. One of my biggest concerns was

getting the sides and bottom aligned correctly and symmetrically. The design and

construction method of Tortoise made this easier. The stitch-and -glue projects I had seen

required aligning all joints at once, while holding pieces together with wires. I worried

that this would produce a group of panels too flexible to stay in shape while the epoxy

hardened . Tortoise plans call for spacers to keep the sides parallel and the same

distance apart top and bottom. The external chines were already cut accurate at the

lumberyard so that accuracy also helped to line up and stiffen the components. |

| Other boats called for a variety of angles in almost all chines

and other joints. Tortoise rarely did. This because of the parallel sides (sheerline to

bottom as well as bow and stern to sides) of the Tortoise. eliminated most of them .

Matching the chine log to the curve of the bottom requires cutting angles, but the same

degree of precision is not required and There are plenty of visual cues to help. So there

was less worry about getting the hull together symmetrically. |

| There was no stem, and no need to rabbet sides to the the stem.

This was good because I didn't know what that term meant and I couldn't even spell it, to

say nothing of actually creating a rabbet. This meant that on the Tortoise there were no

precise angles to chisel out where the sides went into the bow. |

| The only other angle cuts called for on Tortoise are the top

and bottom of the bow and stern transoms. There were no internal frames or bulkheads to

make, as on other boats. Overall, I measured twice and cut once, still ending up with gaps

between pieces that were supposed to have been close fitting. These were quickly and

easily filled with epoxy thickened with wood flour with no ill effect. |

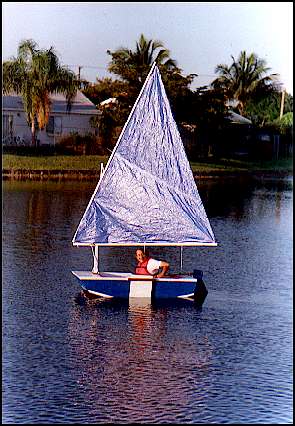

| The result of the Tortoise project? Success. I frequently sail

it on the small drainage lake behind my house. It can be picked up and carried by one

person and I find this to be a real asset. It feels stable, and I have not yet capsized. I

am also thinking about taking it on a 20 mile trip on a quiet section of the intracoastal

waterway. However, the most valuable thing it has provided me is the confidence to take on

a larger project, with reasonable expectation of a positive outcome. My skills seem

sufficient and my ability to stick with the task also seems appropriate. While the

Tortoise really is a very small boat, I feel that building it has helped me to make a

valid prediction about my ability to take on the next larger project. |

|

Based on what I learned about boatbuilding, about

my skills and about my persistence for long term projects, I am now building a 12' Bolger

designed "Oldshoe". Still not quite the bright-finished classic of my dreams,

but at least big and safe enough for the whole family. Maybe the third project will be

that bright-finished beauty. Would I do it

again? Absolutely, only this time I think that I would build the "Big Tortoise".

It is about 18 inches longer, and would probably have the capacity for two adults if they

only require a small amount of personal space. |

| It does not appear to me that building the bigger Tortoise

would be more complex than building the smaller. |

|

SOME THINGS I LEARNED ABOUT BOAT BUILDING

Plan the order in which you assemble the beveled

transoms. Do not glue together first, then cut the bevels. Cut the bevels individually,

then assemble the transoms. I didn't do this and the transoms ended up too narrow. Payson

describes the reason for this on page 42 of "Build the New Instant Boats".

When putting on the bottom, a small mistake in the

angle at the stern transom can result in a much larger failure to line up at the bow. If I

was doing this again, I would consider assembling with temporary screws first, then

disassembling, putting on epoxy and refastening with the permanent screws. If not, mix

small batches of epoxy and work slowly.

It is possible to make cuts of sufficient accuracy

without a table saw. Bevels with a circular saw were within 2 degrees. I filled the gaps

with thickened epoxy. No problems so far

Remember, "things take more time than they

do". I developed a habit of setting goals according to the amount of time I wanted to

put in, not by defining a particular task I wanted to finish that day.

Building a small boat or an "instant"

boat seems very different from a traditional carvel or clinker plank on frame boat. Don't

make the mistake of allowing the apparent complexity of traditional construction defer you

from trying a Tortoise.

I found Time management skills to be as important

as boatbuilding skills. If I didn't make working on the boat a key goal for the day, it

probably would get squeezed out by other less important tasks. There is a video on goal

setting by a fellow named Covey that I saw briefly just once, and these ideas seemed to be

helpful to me.

I've heard it said that it will take almost as long

to put on an excellent finish as it took to build the hull and I believe it. I am happy

with less--- a "workboat" finish of brushed Acrylic Latex exterior house paint

over Kilz primer with the surface sanded with 60 grit paper.

I modified the plans and put the mast at the

midline, used an external daggerboard and a kick-up rudder of my own design.

When I refer to the "Big Tortoise", some

people assume I mean the "Brick", another Bolger boat. They are not in the same

series.

For me, joining an internet users group on

boatbuilding made the whole process more fun, and the consultations were very helpful.

|