|

Little Auk

From Classic Boat No: 108 (June 1997)

Little Auk and several other

classic designs can be

bought as kits from Swallow Boatworks |

SAILING IS a wonderful way of learning the consequences of your actions. The best way, of

course, is alone in a small dinghy, preferably one you've built yourself, so that there is

absolutely no-one else to blame for the mistakes. There

must be a fair number of people whose first water experience took place on some version of

the "old pallet stuffed with pieces of polystyrene and bedsheet sail". This

certainly teaches balance, if no great windward skills. Yet, despite the amateur status in

the boatbuilding field of most would-be sailors, it is not now necessary to start quite so

far back in the evolutionary cycle. There are several kit boats on the market, requiring

varying degrees of woodworking skills. |

| One of the smallest, and surely one of the

simplest, is the 10ft 2in (3.lm) Little Auk. She is designed by Nick Newland, a product of

the Royal Naval College at Greenwich, whose career as a naval architect has involved him

in the design and construction of everything from aircraft carriers to submarines. Nick

knows how satisfying it is to see a vessel take shape under one's hands - whether inside a

computer or a garden shed - and it is to enable the amateur to experience such

satisfaction that he has put such thought in to his design. |

|

| Though Nick does supply finished boats and hulls for home

completion, his main intention is to bring to the market a kit boat such that the

potential sailor can play a major part in the creation. Bearing in mind that sailing and

boatbuilding are different skills, Nick has concentrated on making the process easy and

enjoyable for woodworkers of most skill levels, with a boat that he hopes can accommodate

the same range of sailing skills: "If you can use a plane," says Nick, "you

can build the Little Auk." |

|

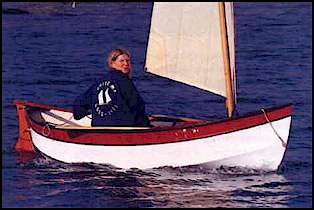

Double-ended, with a beam of 4ft 4in (1.3m) she is

small enough to fit into a garage and simple to assemble. There are two wide panels each

side of 4mm (1 /4in) ply with slightly vee-ed bottom, strengthened and protected by fairly

substantial bilge runners. Construction is simple: the tried-and-tested 'stitch and glue',

sealed with WEST epoxy. The panels are laser-cut, the holes pre-drilled to take the copper

wire stitches. To create the overall shape of the boat you just lay out the pieces and sew

them up, so that after only a short day's work, one can see the hull coming together. |

| The seams are then glass-taped with epoxy and you're onto the

next stage, which is no more complicated. All the pieces of hardwood that transform the

bare hull into a solid little sailing craft are mahogany, cut to shape and size, even down

to the rounding of the edges. This means that a professional-looking finish is a matter of

sandpaper rather than plane. The only bevels that Nick has left uncut are those at the

stem and stern as he feels that, however uniform it may look, each piece of plywood bends

differently. Rather than risk an ill-fitting joint that would have to be bodged with

filler, he has left them to each individual builder. |

| Being plywood, with bulkheads fore and aft, the

boat is strong for her hull weight of 651b (30kg) and even stronger for the bilge runners.

At the gunwale, the end-grain is protected by a mahogany capping which runs round the

whole boat, with triangular knees at the stem and stern. Cheeks take two pairs of

rowlocks. |

|

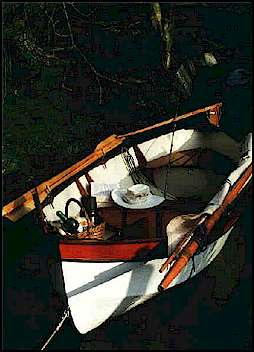

| Her appearance is enhanced by a pretty sheer and wide band of

contrasting colour that breaks up what could be rather slab-sided top-sides. The

sternsheets are made up of two curving side-pieces with a centre triangle that can be

removed to insert a buoyancy bag. Another is strapped under the middle thwart. |

|

Forward, the daggerboard casing and mast step are

models of simplicity. A single piece of mahogany nests on a support right in the bow,

running aft over the bulkhead to form the cap-ping for the daggerboard trunk. The mast is

stepped through a keyhole in this into a step just forward of the bulkhead. |

| The rudder has a relatively wide, shallow blade, fixed for ease

of construction, which extends just below the level of the keel. When I asked Nick whether

it wouldn't have been better to forego some area rather than risk damage when grounding,

he pointed out the long upper pintle, which allows it to slide up, and there is the added

provision of a pin on a lan-yard securing tiller and rudder to the boat. |

| She has that most straightforward of rigs, a

high-peaked lug, with the mast short enough to fit into the boat and needing no stays. The

spars are supplied already roughed out. The halyard is attached to the yard about a third

of the way along it, leading through a dumb sheave at the masthead to a cleat at the foot.

To step, the mast is dropped into the keyhole in the fore-and-aft thwart and swiveled 180

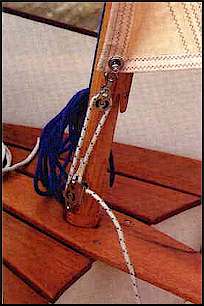

degrees to lock it into position. The sheeting

arrangements are unusual. As the little Auk has no transom and there is no obvious place

for the customary fixed sheet horse, Nick has come up with an ingenious adjustable rope

horse involving lance cleats, as used on racing dinghies. |

|

| Rather than having the mainsheet block shackled around the

horse, the rope horse here has a loop spliced into the middle of its length, through which

the sheet block is shackled. The ends are led through the lance cleats positioned on the

gunwale at each aft quarter. The correct sheeting position when hard on the wind is with

the loop at the leeward cleat. When tacking, one frees the horse and, as she comes through

the wind, hauls it over to the other, newly leeward cleat. The result is a sort of

traveler in reverse, an interesting solution to the ever-present problem of sheeting

arrangements on a small double-ender. |

|

Nick brought his own Little Auk by car from

Cardigan to Falmouth, proving she is 'car-toppable', with none of those hidden pounds that

make you wonder what sort of Hercules the ad-men employed for the brochure. It is more

convenient to have a person at either end when lifting or lowering the boat, but it is

possible to do it alone - a sensible feature on a boat so suited to single-handing. |

| Her spars, including the sail bent onto the yard, fit in a bag

inside the hull and rigging her is simple. The oars extend out from the bows over the

forward rowlocks, but it is difficult to accommodate them safely anywhere else. In sunshine and a gentle breeze we discovered that sailing the Little Auk

takes a little getting used to, but Nick is always open to suggestions. The seated

position is sideways on the centre thwart, with one's feet aft so as to manipulate the

horse. There's a knack to it that, once grasped, wasn't difficult. |

| Going into a tack you put the helm down and,

leaving the boat to carry on through, you free off the horse at the lance cleat next to

your hand. As she goes through the eye of the wind you slide along the thwart, hauling in

the other end of the horse as you go. I found it disconcerting at first, turning my back

on the bow during the operation as well as keeping hold of the mainsheet, but we never

missed a tack, though there were some pretty untidy ones. Luff tension is adjusted via a tack line through a block at the foot of

the mast. The conditions I was sailing in, with a wind shadow near the shore and a rising

3 further out, meant that I was playing the tack rope like a sheet. Luff tension makes a

significant difference to the set of a lug sail and what was appropriate for the stronger

breeze was too tight for the calms. One can split the difference, of course, but it's

satisfying to have it right and with the line handy there's no reason not to. |

|

| The daggerboard is adjustable too, with a simple wedge. Nick

had told me she would sail to windward with the board up, and I must admit that I doubted

him, as Little Auk hasn't much keel. But sure enough - probably because of those bilge

runners - we ghosted around a windward buoy with no trouble. |

Going like a

train

| Off the wind, she went like a little train and here the horse

arrangement really came in useful. The loop can be eased out so that the sheeting point is

outboard, allowing the sail, a little beauty cut by Mark Williams of Ratsey Sail-makers at

Milford Haven, to set really well. |

| When the wind piped up, I scooted back in to more

sheltered water and, wrapping the painter round the sail to douse it, set to with the

oars. With 7ft (2.1m) oars and such a light hull, she flies along. |

|

|

Back at the slipway we discussed

little Auk's pros and cons. Though I felt that the adjustable-horse added complications to

the superbly simple rig, I could think of no better solution. One could compromise by

leaving it cleated with loop amidships without too much loss of sail shape. But, as with

the luff tension, if you want harmony, you have to tune your instrument. I would however

recommend a brailing line. It makes furling so quick and easy and need not interfere with

the set of the sail at all. The hull kit, which

includes everything except the paint, costs £820, with the sailing accessory pack a

further £350. Completed, ready to sail boats are an added £875, all including VAT. |

| Nick has certainly thought through the design and

the practicalities of amateur building with a blow-by-blow manual and 8am-lOpm helpline. Little Auk fulfils her brief admirably. She's good to look at, simple to

build and fun to sail. Though designed primarily as a 'car-topper', she is a versatile

yacht tender, easy to lift, capable of carrying four adults under oars, yet perfect for a

quiet solo sail around the anchorage. The only problem I can see would be in wresting her

away from the children. |

|

|