|

Somerset

by Martin Ellacott ellacott@mnsi.net

Somerset represents the latest endeavor

in a series of small boats that I have built, and was designed by Sam Devlin of Washington

State. The hull is built of 1/2"; exterior grade plywood, good two sides. All

the exterior wood is Brazilian mahogany. The decks are strip plank mahogany and West

System epoxy. As a matter of fact, West epoxy was used exclusively for all coating,

gluing, and glassing operations. The bottom of the 1/2" hull has a 1/4" layer of

plywood cold-moulded to it and is covered with 2 layers of 6oz. fiberglass. The sides of

the hull and the cabin roof have a single layer of 6oz. glass. The 3/4" decks

are a lamination of 3 layers of 1/4" plywood formed over the bulkheads. |

The transom, cabin roof and the top of

the motorwell cover, were made the same way except that separate forms had to be built

first. From all appearances, the boat looks as if it has an inboard motor, when in

actuality a 60HP outboard motor is bolted to an interior transom, hidden under the motor

cover. All bulkheads and floors are 3/4", exterior grade plywood, with the

interior of the hull given several coats of epoxy. |

|

The interior joints and bulkheads are

filleted using a combination of screened mahogany sawdust and epoxy, and then triple

glassed. The exterior seams and joints are all double glassed. When the hull was

returned to the shop after being turned over, the deckhouse was totally pre-fabbed,

waiting for warmer weather so it could be finished outside. When finished, Somerset

will have all the necessary equipment for this small coastal cruiser to spend extended

periods of time away from her home port in Sarnia, Ontario. |

#1.....After 14 months, Somerset

finally emerges from the shop. At this point, the hull is completely finished and the

interior structures have been roughed in.

|

|

|

#2..The main bulkhead has been

reattached. It had to be cut in two to accommodate turning the hull over, and later,

moving it out of the shop. It has also been splined to maintain its integrity.

|

#3...After end of the boat, showing the

3/4" laminated transom and cockpit drains.

|

|

|

#4.....Attachment of the pre-fabbed

cabin side. Also shows some of the detail of the motor cover.

|

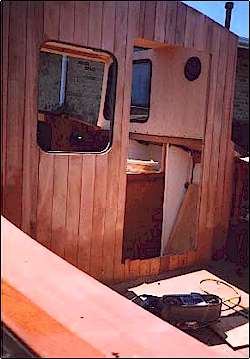

#5.....Cabin sides permanently glued

and screwed in place. The window shows the epoxied insert that has been routed out to

accommodate the 3/16", tempered glass which is flush fitting.

|

|

|

#6....Exterior of the deckhouse is

completely finished. The companion-way door slides horizontally for access to the cabin.

|

#7......Finished exterior, showing the

mooring bit and the scupper for the footwell located at the bow.

|

|

|

#8.......Pitman crane and lifting

harness. In this position, it can be seen that about 14" of the after end of the keel

have been removed to facilitate sharper turns in confined areas.

|

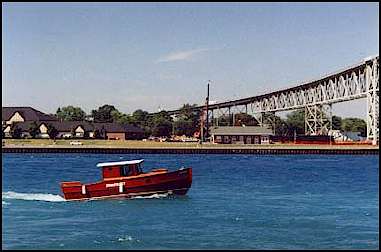

#9.....In the water at

last,approximately 2 years from the start of the project. The bridge in the background

joins Sarnia, Ontario and Port Huron, Michigan. This area is one of the busiest waterways

in Canada.

|

|

|

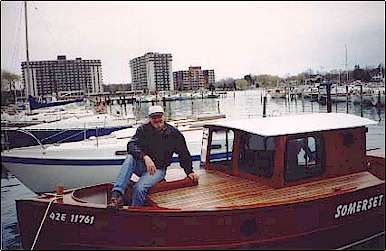

#10.....Boat and builder in the Sarnia

Yacht Club at the end of the sailing season.

|

|